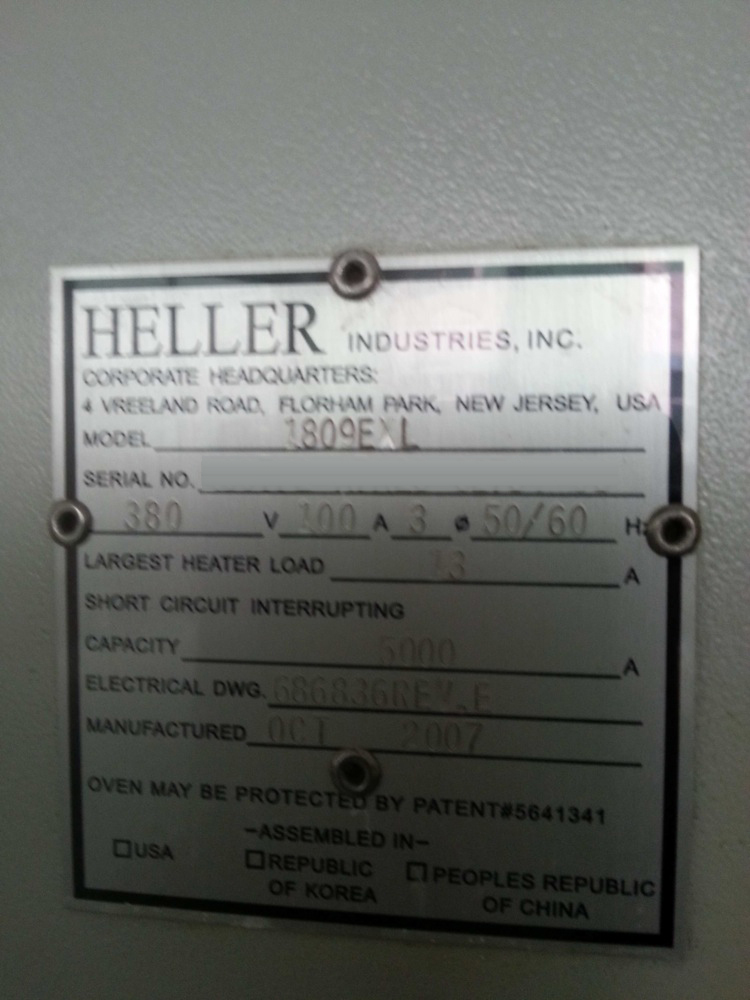

Used HELLER 1809EXL #9040486 for sale

URL successfully copied!

Tap to zoom

ID: 9040486

Vintage: 2007

Reflow oven

Hours: 40,214

Center board support

Uninterruptible power supply

Automatic chain oilers

Computer with software installed

Installed software supports CBS

2007 vintage.

HELLER 1809EXL is a high performance reflow oven designed for use in automated soldering processes. It features a fully programmable advanced temperature control equipment, allowing users to adjust the reflow profile to suit their specific applications. Utilizing advanced microchip based PID system, HELLER 1809 EXL ensures extremely accurate temperature control at all points in the reflow process. The reflow oven is capable of holding up to 500 x 50mm size boards and accommodates 960mm long product leads. High speed conveyorized operation ensures product accuracy at speeds of up to 20,000 parts per hour. The integrated thermal monitoring unit provides real-time thermal data and graphical feedback which records the entire process. This allows users to retrospectively analyze the process and condition of their entire reflow operation. 1809EXL is equipped with a self-contained thermal source, consisting of four heating elements placed within the reflow chamber. These heating elements are configured to produce a uniform heat profile, allowing for a reduction in energy consumption without compromising the quality of results. The oven is equipped with an advanced airflow machine which eliminates hot spots and delivers superior process uniformity to the solder joint. The new low-air flow tool produces a gentle turbulence which carries the board smoothly through the reflow process and evenly distributes heat throughout the chamber. An integrated data logging asset allows for performance data to be tracked and stored for future analysis. The model also features an intelligent auto-tuning equipment which allows for optimal tuning of the oven each time it is powered up. Overall, 1809 EXL Reflow Oven is an advanced and reliable solution for automated soldering processes. The reflow oven offers superior reflow performance, improved process uniformity, reduced energy demands, and control over the process environment. Users can be assured of reliable and top-quality finished products.

There are no reviews yet