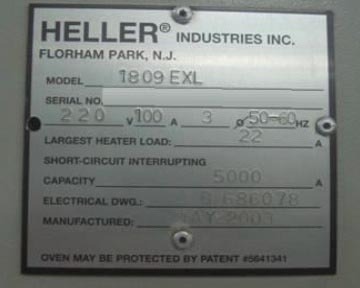

Used HELLER 1809EXL #9067198 for sale

URL successfully copied!

Tap to zoom

ID: 9067198

Vintage: 2003

Reflow oven

Nitrogen

(8) Zones

Flow: Left to right

Front fixed rail

Lead free

220V

2003 vintage.

HELLER 1809EXL Reflow Oven is a high-performance, mid-level reflow oven designed for bakers in industrial settings. The machine is well suited for producing large-scale reflow soldering projects, as it incorporates several advanced features and processes. Measuring 3.23 feet wide, 4.5 feet deep, and 7.56 feet tall, HELLER 1809 EXL houses a wide reflow chamber that is able to accommodate full-sized panel boards without a need for an auxiliary board loader. This helps to streamline the production process while maximizing component placement accuracy. Additionally, the unit features eight independent heating zones, each capable of selectively heating the top or bottom of a board with precision. For optimal temperature control, 1809EXL reflow oven is equipped with three different temperature profile modes: Hot Air Knife, Zone, and Crossover. The Hot Air Knife mode is used for items which require a high-temperature preheat stage prior to soldering. The Zone mode selectively heats the top of the board with steam while simultaneously cooling the bottom of the board. Finally, the Crossover mode maintains comparable temperature across the reflow chamber by advancing the hot air knife across the reflow chamber's surfaces. 1809 EXL also incorporates several safety features, such as a safety-rated gas leak detector with automatic shutoff. Additionally, the unit has a variable speed exhaust port, which helps to remove heat-sensitive components from the operator's work area. For convenience, the machine offers a pivoting front loading door, as well as two different types of conveyor rollers: traditional and ventilated rollers, depending on the work order. HELLER 1809EXL Reflow Oven is designed to provide reliable performance and maximum efficiency to bakers in medium- to large-scale settings. Its wide variety of features and settings make it versatile in both standard production processes as well as those which require significant customization. The machine is also highly configurable, making it easy to custom tailor it to a given application.

There are no reviews yet