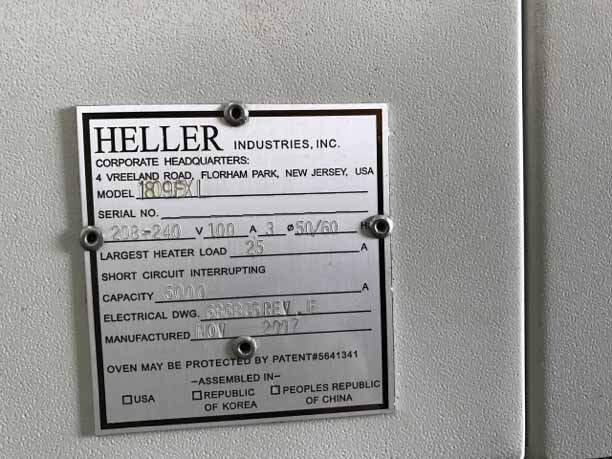

Used HELLER 1809EXL #9177774 for sale

URL successfully copied!

Tap to zoom

ID: 9177774

Vintage: 2007

Reflow oven

Left to right

Mesh and chain type

2007 vintage.

HELLER 1809EXL is a reflow oven. It is a full-featured, configurable model that provides fast, uniform and reliable heating to support a range of PCB assembly and rework operations. HELLER 1809 EXL offers convective, vapor phase and infra-red reflow heating technologies for excellent performance on component accuracy and device reliability. It is an ideal machine for use in electronics production due to its easy-to-use operation, precision temperature control, sophisticated air flow management, and the optional integrated capture equipment. The maximum temperature of 1809EXL is 500°C and the maximum convection heating is 28°C above set temperature. Pre-heating time on standard production boards is less than 3 minutes with an atmosphere temperature of between 20°C to 25°C. Post cooling time with a HP roll module is less than 8 minutes. The reflow oven also features a built-in PLC panel for easy operation and fault diagnosis and allows profiles to be stored, copied, and edited. With the optional profile recording, the machine can capture waveforms from the output sensors (IR 1 and IR 2) enabling complete traceability and quality control. The included air flow management system features adjustable temperature nodes for up to 10 lateral zones, allowing users to adjust each zone's temperature independently for greater accuracy. In addition, the integrated O2 gas sensor unit helps operators keep the reflow atmosphere oxygen levels low enough to keep adhesive processes free from oxidation and provide improved product soldering quality. The oven also features a split chamber design, providing flexible setup with separate top and bottom heating zones. 1809 EXL is designed for maximum safety and convenience, featuring a sensor-based door closer and exit zone cooling machine that cools the Profile while the lid is still open. The overall dimensions of the machine are 721mm (w) x 705mm (d) x 2296 (h), and it also includes a robust collection of alarms and warnings with full operating history logging. It provides excellent performance even when processing complex components and PCB's with high densities, making it an excellent choice for a variety of production and rework operations.

There are no reviews yet