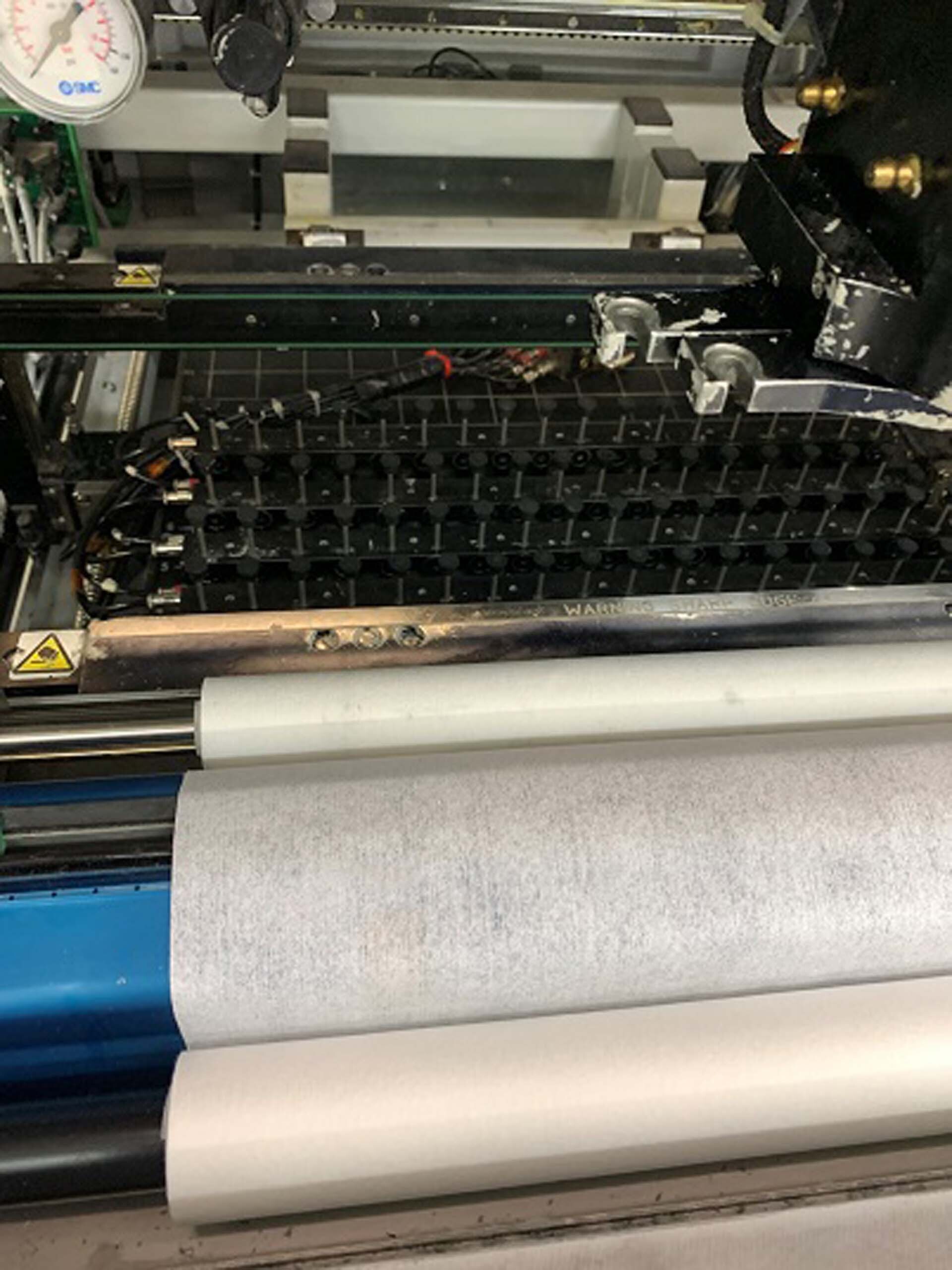

Used DEK 265 #293634528 for sale

URL successfully copied!

Tap to zoom

DEK 265 screen printer is a versatile and highly customizable instrument developed by DEK that meets the industry's needs for high-volume automated production. 265 is a robust and reliable machine capable of delivering high precision performance in a range of printing applications. DEK 265 has been developed to create a streamlined, cost-efficient and accurate printing solution that meets the industry's most demanding print requirements. 265 offers a variety of features to make automated production more efficient, accurate and reliable. A sturdy and robust chassis offers enhanced rigidity, enabling optimisation for accuracy and stability. The powerful user-friendly controls allow for faster setup and more intuitive operation. Wear-tested and precision components ensure a lifetime of repeatable and reliable use. DEK 265 is designed for high-volume screen printing applications. The tool-less stencil exchange equipment allows for faster and repeatable setup and effortless production changes. The precision registration system ensures accurate location of parts on the substrate. The advanced vision unit ensures precise placement of parts on the substrate and enables part visibility during production. 265 is a flatbed screen printer, which minimizes cycle times and maximizes throughput. The rigid construction allows for repeatable printing accuracy, while an adjustable squeegee motion profile ensures optimal stencil cleaning and printing performance. The optimized design and construction effectively resist heat, allowing for consistent curing temperatures, while conformal-coated PCBs can be reliably printed. DEK 265 is a true all-in-one production platform, offering integrated in-line conveyors, aerial vision inspection and a high-performance electrical feeder. The integrated material handling machine helps to ensure repeatable and accurate part recognition. The high-performance electrical feeders have been designed to meet the demanding needs of high-volume automated production, with features such as global index and de-panel operation. The integrated in-line imaging and inspection systems enable 265 to provide the automated, high-precision production demands of the industry. The tool inspects up to 12 layers of the substrate for defects, ensure that each part is accurately placed for paste printing, inspects solder paste before print, inspects the board for correct pattern placement, and performs post-print inspection. DEK 265 is a versatile and customizable printing solution, proven to optimise production operations. With its robust, reliable construction and versatile features, 265 offers a streamlined solution that meets the industry's most demanding needs.

There are no reviews yet