Used DISCO DAD 2SP/6T #48113 for sale

URL successfully copied!

Tap to zoom

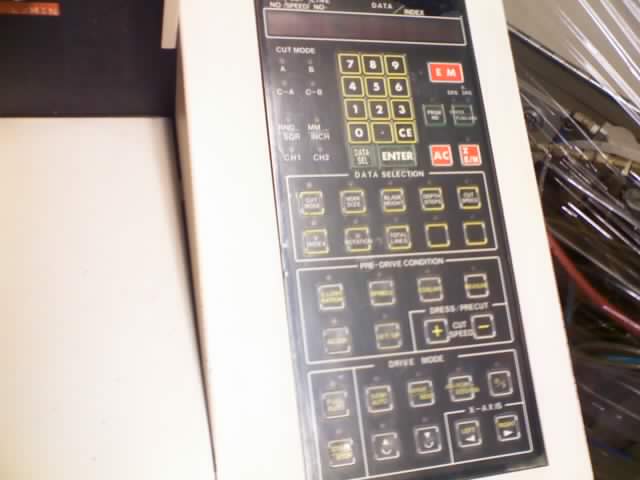

DISCO DAD 2SP/6T is a "scribing / dicing" equipment used to produce high-precision, repeatable and accurate parts made of hard and soft materials. This system is comprised of an electrospinning and scribing tool, with a total of six working axes. The electrospinning tool contains two motors and a tachometer. These motors spin at speeds ranging from 2 to 36,000 rpm and are individually adjustable. This allows for a wide range of possible diameters. The scribing tool has six axes of work, which allows it to produce more complex shapes. The unit features a cutting-edge digital control machine that is able to read a CAD file and convert it into machine commands. This makes it easy for users to program their own shapes and easily make changes to existing programs. The tool also features a pattern recognition and correction asset. This helps reduce downtime and increases accuracy of parts being produced. DISCO DAD 2SP/6T is also integrated with various materials compatibility features. It supports a wide range of materials such as copper, stainless steel, aluminum and titanium. Also, it is capable of cutting both hard and soft materials, making it an ideal tool for precision parts fabrication. This model also has a variety of options available in terms of performance enhancements. For example, it can be integrated with servo-controlled feeding technologies that can enable production of parts with much greater accuracy and detail. It also has an offline programming function that allows users to program their designs and shapes without having to worry about machine setup. In summary, DISCO DAD 2SP/6T is a highly advanced scribing and dicing equipment that is suitable for a variety of applications. It is capable of producing parts of high precision, repeatability and accuracy with its two motors, tachometer and six axes of work. The system also has integrated material compatibility and performance enhancement features, along with an offline programming feature. This makes it a highly effective tool for precision part production.

There are no reviews yet