Used ZEUS TS1400-H #9188133 for sale

URL successfully copied!

Tap to zoom

ID: 9188133

Wafer Size: 6"

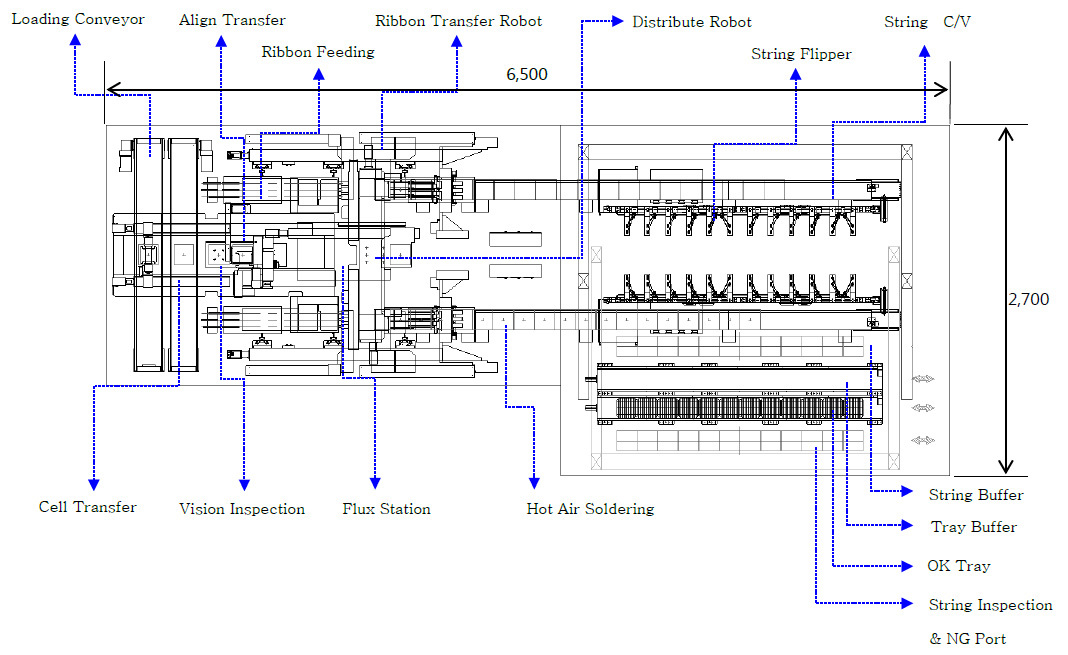

Tabbing / Stringing system, 6"

Specifications:

Type: Auto

Cell type: 2 & 3 Bus bar

Solar cell size: Mono and multi cell

Solar cell thickness: >160μm / 180μm mono (standard)

Cell: Auto

Magazine: Manual

Ribbon: Auto

Ribbon roll: Manual

String: 1~12 Cell (Auto 8~12 cell)

Ribbon:

Ribbon type: Pb & Pb free ribbon

Ribbon width: 1.5 mm, 2 mm

Solar cell spacing: 1.5-30 mm / 2.0 mm (standard)

Solar cell spacing accuracy: ±0.3 mm / 2.0±0.3 mm (standard)

String length: 156-1920 mm, ±1 mm

Vision align accuracy: ±0.1 mm

Ribbon position accuracy: ±0.3 mm / based on bus line center

Throughput: <1,400 cells / hr [cell to cell: 2.5 sec]

Breakage: <0.3% / base on the H/W issue [180um]

Technical availability: >95%

Noise level: Maximum 72 dB(A)

Electricity: 3Ф 380 V, 60 Hz, 66 kW

Compressed air: 0.6 MPa, 3000 L/Min / (8) Ф12 tubes

Gen exhaust: <360 m3/h / Ф200

Heat exhaust: <360m3/h / Ф125

Configuration:

(2) Loading conveyor units, free flow top chain conveyor

(10) Magazines, cell stock: 200EA/Magazine

Cell Wafer transfer robot, 2 axis cross robot (cell W/F transfer)

Align transfer robot, 4 axis linear

Vision inspection unit, 5 MP CCD camera, back light (LED)

NG port, NG bucket

Flux station unit, flux nozzle (dispensing type)

Distribute robot, 2 axis linear (cell W/F transport and distribution)

(2) Ribbon spool units, spool diameter: Ф160≥

(2) Ribbon feeding units (clamping / stretching / bending / cutting)

(2) Ribbon transfer robots, vacuum type

(2) String C/V unit, steel belt type, heater & vacuum conveyor

(2) Soldering units, hot air soldering

(2) String flippers, string reverse

String buffer, tray supply unit [steps: 5] + OK tray unit [steps: 5]

Signal tower & melody, warning and alarm

(5) EMO S/W, emergency switch

Operation panel, top swivel type orthotic

Includes:

Control panel

PLC / Electronic parts.

ZEUS TS1400-H is a high efficiency, state-of-the-art solar production equipment designed to produce the highest quality photovoltaic panels with maximum efficiency. TS1400-H employs a range of advanced production technologies to deliver unprecedented performance and reliability in the production process. ZEUS TS1400-H utilizes ultra-thin film deposition technology to ensure optimal energy conversion from sunlight. With a film thickness up to 0.060mm, the deposition equipment is able to achieve extremely precise conversion efficiency, while maintaining superior stability over the long-term of a photovoltaic panel's life. TS1400-H also features an automated cell positioning system, which increases production throughput and reliability. With a precision of up to 2µm accuracy, this unit significantly reduces cell misplacement, which can improve efficiency and ensure the highest quality of production. ZEUS TS1400-H also utilizes a highly accurate laser scribing machine, which performs the critical task of cutting photovoltaic cells for connecting and stripping. This allows the panels to be created in a fraction of the time compared to conventional scribing processes, while ensuring precise and reliable connections. TS1400-H also features the latest in inspection and testing automation, with defect detection capabilities that can provide a reliable assessment of the quality of the photovoltaic output. With sophisticated vision algorithms, the automated inspector uses a range of features to assess each cell for production quality. Finally, ZEUS TS1400-H comes with advanced software for tool control and analysis, as well as various safety features including emergency stop and safety fencing. This allows for easy integration into existing production systems. Overall, TS1400-H provides the highest levels of quality and performance, thanks to its advanced production technologies and sophisticated automated inspection and testing systems. It is designed to deliver reliable production of high quality photovoltaic cells, without sacrificing quality or efficiency. This cutting edge technology makes ZEUS TS1400-H the perfect choice for any photovoltaic production application.

There are no reviews yet