Used CPA / KURDEX 9900-1 #9173356 for sale

URL successfully copied!

Tap to zoom

ID: 9173356

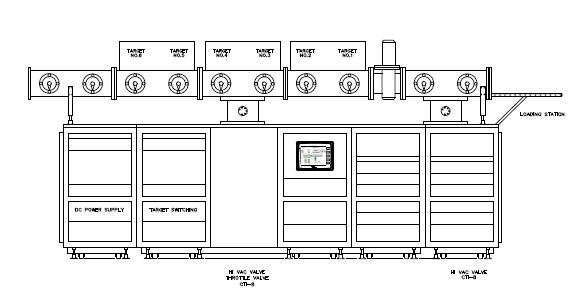

Horizontal in-line sputtering system

Entry / Exit load lock:

CPA Chamber

CPA Load lock valve

Load lock chamber 26"

Single pallet operation

12” x 24” Sputter zone

(1) Al Pallet, 15.5” x 25” x .25”

MKS 924 Multi-gauge for vacuum

Measurement ATM to -8 Scale

Pallet sensors

Process chamber:

CTI CT-8 Cryo pump

VAT Hivac valve

MKS Throttling valve

CTI 8500 Compressor

MKS 972 Multi-gauge for vacuum

Measurement ATM to -8 Scale

(2) Gas system with VCR gas lines

(2) NUPRO Isolation valves

(2) MKS MFCs for Ar 200 sccm , O2 50 sccm

MKS Variable throttle value

MKS 390 Baratron gauge

Chain drive transport system

AE Pinnacle+, 5 kW DC power supply

With sync cable

(4) CPA Process chambers:

(6) CPA 4.75” x 15” DC Magnetron assemblies

(6) Targets shielding

(1) CPA Process chamber

Oven run

Control system:

Opto-22 PLC

Monitor-simple PLC

Manual and auto control modes

Recipe control

(2) Stepper motors

I/O Wiring

SMC Soleniod block

UL Approved power box with EMO

CPA Optical pallet sensing system

With controller and sensors

RGA:

LEYBOLD Transpector

Installed with isolation valve

Dry pump.

CPA / KURDEX 9900-1 sputtering equipment is a magnetron-based system specifically designed for thin film deposition applications. It is a high-precision, multi-target unit that is perfectly suited for sputter-coating with a variety of materials. CPA 9900-1 has a maximum deposition rate of 0.3 Å/s, a target-to-sample distance range of 3 to 10 cm, and a maximum substrate size of 9 inches. It is also capable of sputtering both positive and negative targets. The machine is powered by an automated Argon-ion source and is equipped with a special, ultra-high vacuum (UHV) triple target magnetron sputtering gun. KURDEX 9900-1 is equipped with a variety of features, including a touch-screen display for ease of operation, a fully enclosed design for safety, and an LED display for target monitoring. The tool is additionally equipped with a PLC (Programmable Logic Controller) for optimized automation and precise control over the asset's sputtering processes. The model can also be integrated into an automated production line, allowing for fast and efficient sputter-coating of increments in patterned thin films. 9900-1 uses a high-power, specially designed plasma generator to create the optimum sputtering conditions. The sputtering parameters in this equipment are highly adjustable and can be programmed for optimum results. The maximum process temperature range is 0-1000˚C, and the maximum power output is 8kW. The system is further equipped with a water-cooled shield to ensure safety and reliability. CPA / KURDEX 9900-1 is an ideal choice for high-performance thin film deposition applications. Its exceptional precision and speed make it well suited for quickly and efficiently sputter-coating with a variety of materials. The unit is also equipped with several safety and monitoring features to protect the operator and the substrate from any potential interference. CPA 9900-1 is an accessible and cost-effective option for high-precision, high-performance sputtering applications.

There are no reviews yet