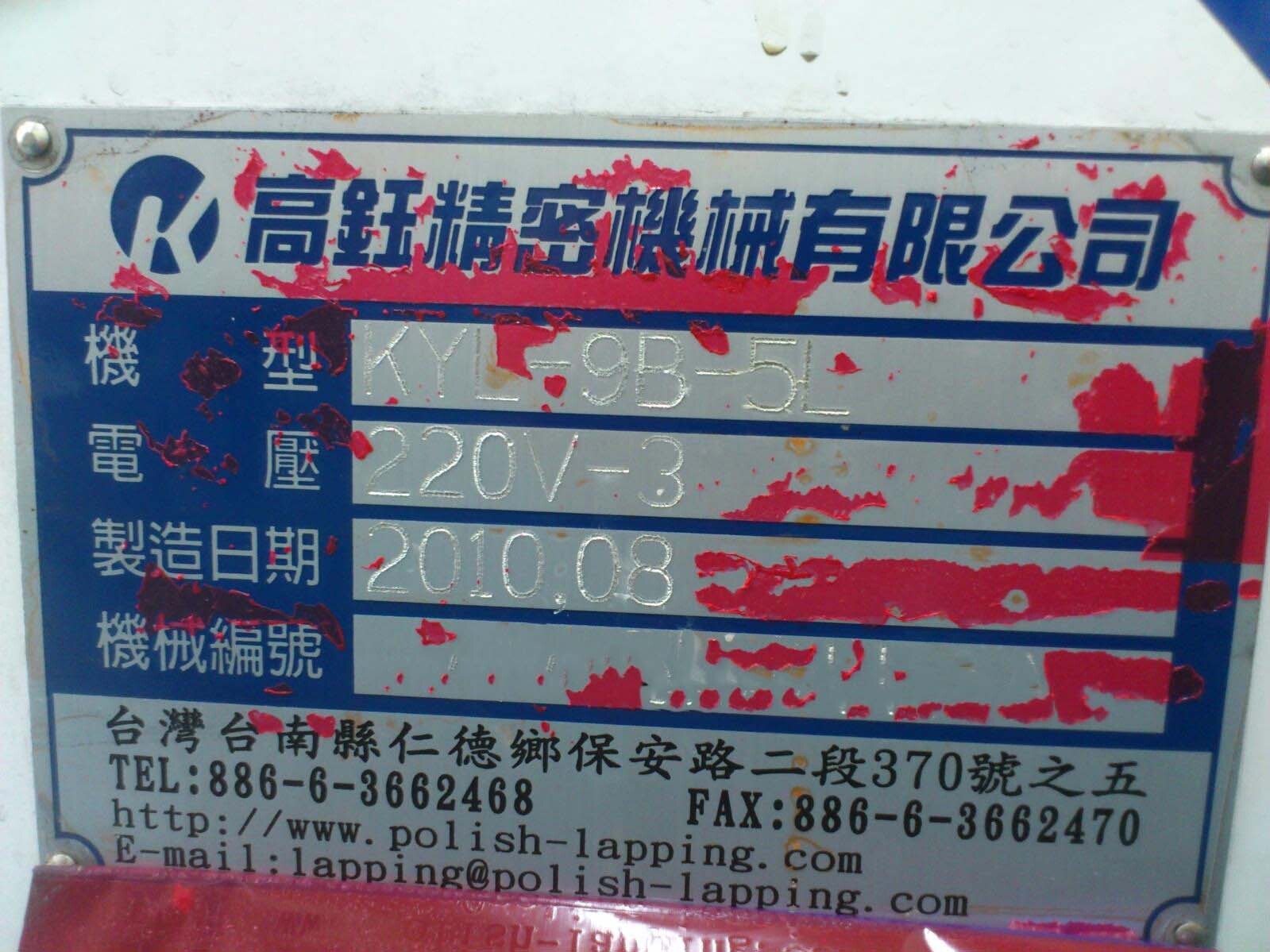

Used KAO-YU PRECISION MACHINERY KYL-9B-5L #293638088 for sale

URL successfully copied!

Tap to zoom

ID: 293638088

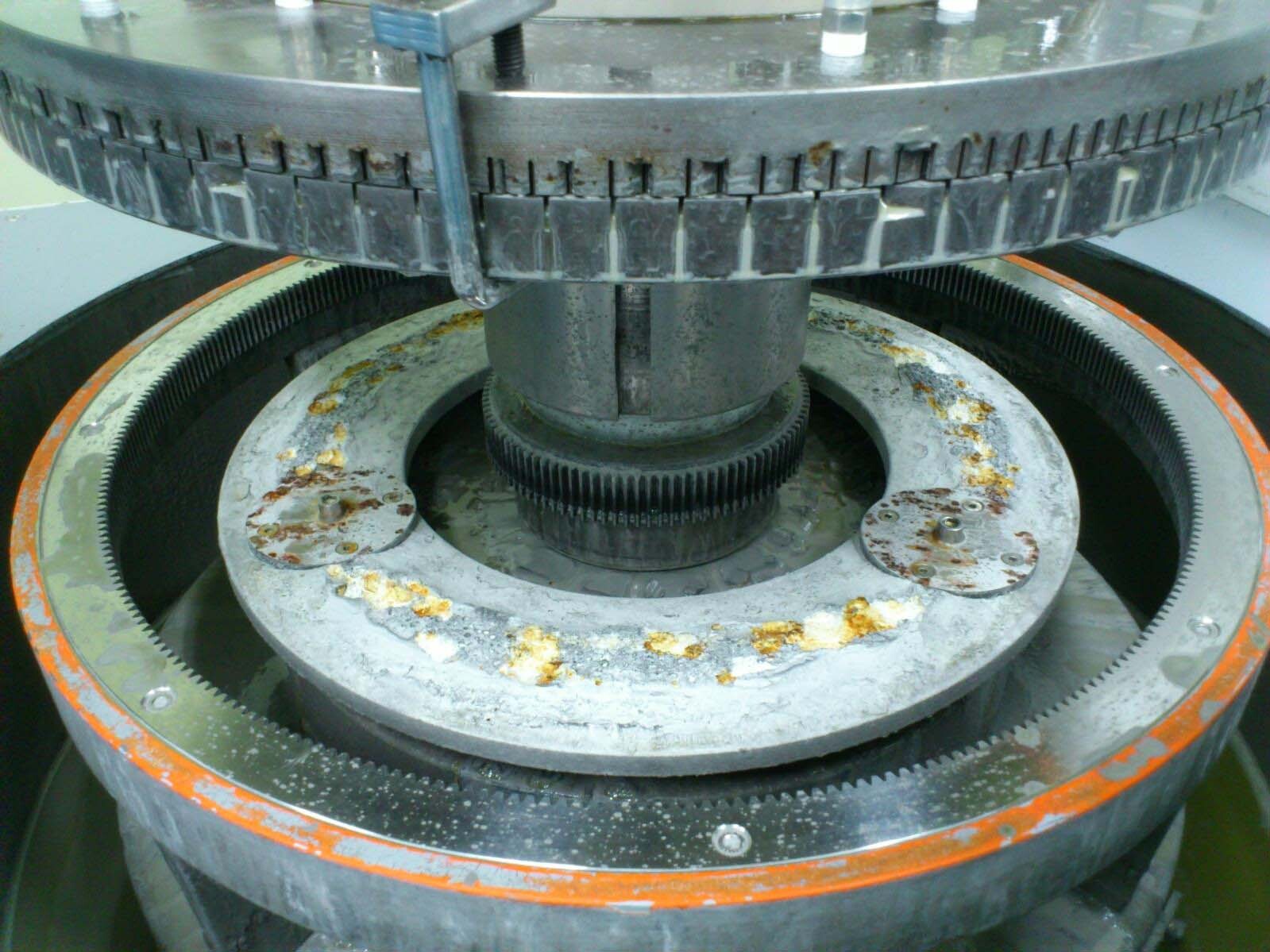

Double sided lapper / grinder

Maximum diameter: 200 mm

Minimum thickness: 0.15 mm

Maximum thickness: 70 mm

Speed of lower plate: 0-60 RPM

(5) Clamping apparatus

Driving motor: 6.75 kw

Slurry motor: 0.4 kw

Air pressure: 6kg/cm²

Power supply: 220 V.

KAO-YU PRECISION MACHINERY KYL-9B-5L wafer grinding, lapping, and polishing equipment is designed to accurately shape and finish components for a variety of applications. This system utilizes a combination of grinding, lapping, and polishing techniques to process silicon and compound semiconductor wafers, flat components, and ceramic substrates. KYL-9B-5L is specifically designed for dual-sided processing and features automated, in-situ tool monitoring and control capabilities. KAO-YU PRECISION MACHINERY KYL-9B-5L features a PLC-controlled main drive motor which allows for precise control of the wafer's angular displacement and velocity. This unit is also equipped with a high-precision up/down reciprocating linear slide unit that enables the grinding head to effectively and accurately traverse the full length of the wafer. KYL-9B-5L also includes a servo-driven platform for precise end effector positioning and load handling, allowing for precise power/torque control. In addition, this machine utilizes a rotating diamond abrasive grinding wheel for precise wafer grinding. The grinding head also features a motorized wafer rotation mechanism, providing precise control of the wafer's rotation angles and speeds. KAO-YU PRECISION MACHINERY KYL-9B-5L also includes a customized frequency inverter and PLC to ensure optimal grinding, lapping, and polishing performance. The lapping station of KYL-9B-5L is equipped with an advanced servo-driven table tool that ensures precise repeatable motion of the lapping plate. This precise motion also ensures that the lapping plate contacts the wafer surface uniformly. The polishing station of KAO-YU PRECISION MACHINERY KYL-9B-5L utilizes a precise linear slide asset with a range of 180° of motion, offering the best in polishing performance. KYL-9B-5L is designed according to the customer's precise requirements, providing ultimate versatility and flexibility. KAO-YU PRECISION MACHINERY KYL-9B-5L is not only capable of spindle speeds up to 160,000rpm, but also features a wide range of process parameters which can be adjusted to meet the requirements of any specific application. Automated, in-situ monitoring and control during and throughout the entire process also ensures consistent quality control. Furthermore, KYL-9B-5L also offers several options for post-processing, including electron beam lithography, etching and chemical-mechanical planarization (CMP). Along with these post-processing options, KAO-YU PRECISION MACHINERY KYL-9B-5L also includes a range of data acquisition and evaluation software, allowing for easy integration with existing process control systems. Overall, KYL-9B-5L wafer grinding, lapping, and polishing model is an advanced and precise tool capable of producing the highest quality finished products in a wide range of applications. With its advanced servo-driven motion, precise linear slide equipment and customizable process parameters, KAO-YU PRECISION MACHINERY KYL-9B-5L ensures optimal performance and a consistent result, whether for research, industrial or metrology purposes.

There are no reviews yet