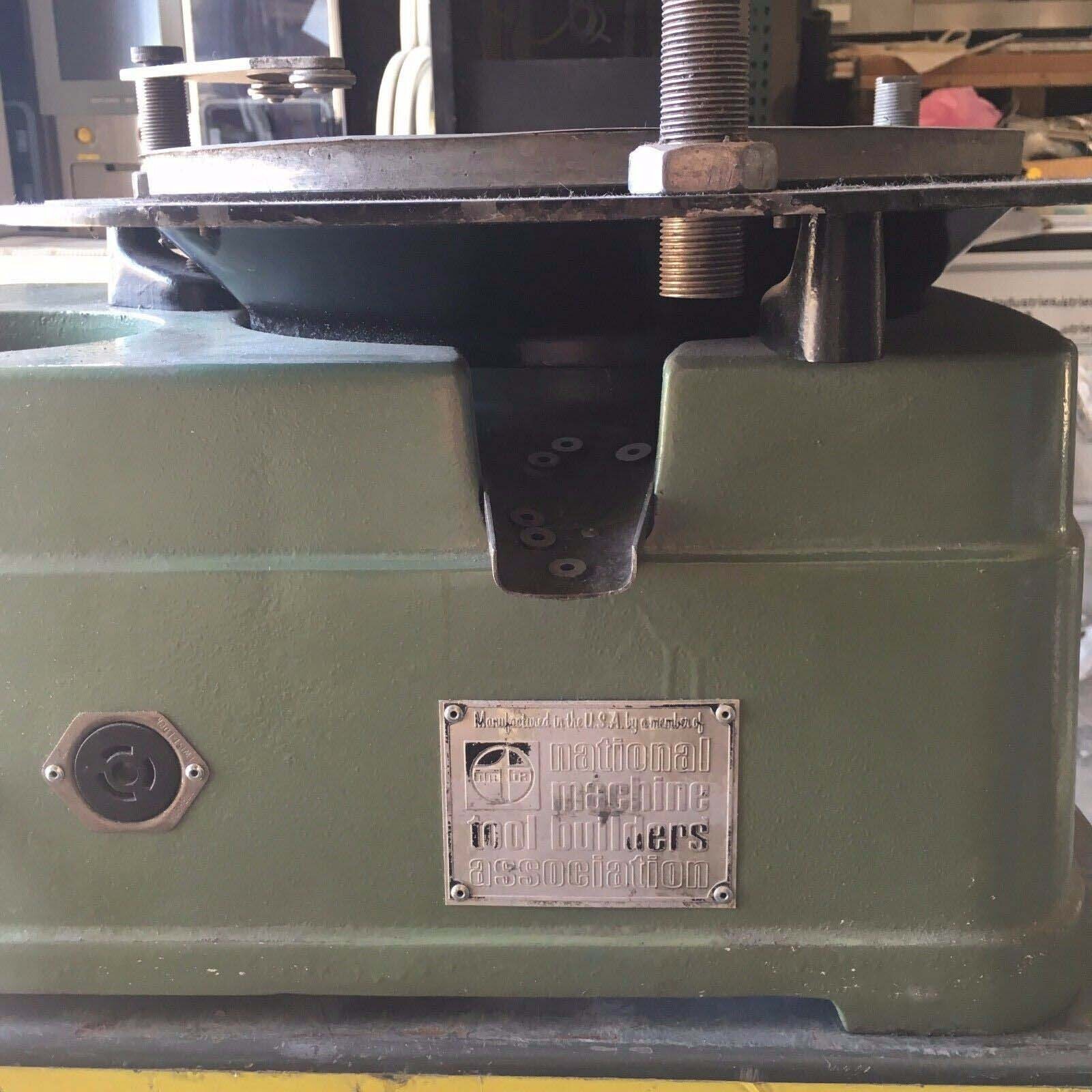

Used LAPMASTER 15 #9329331 for sale

URL successfully copied!

Tap to zoom

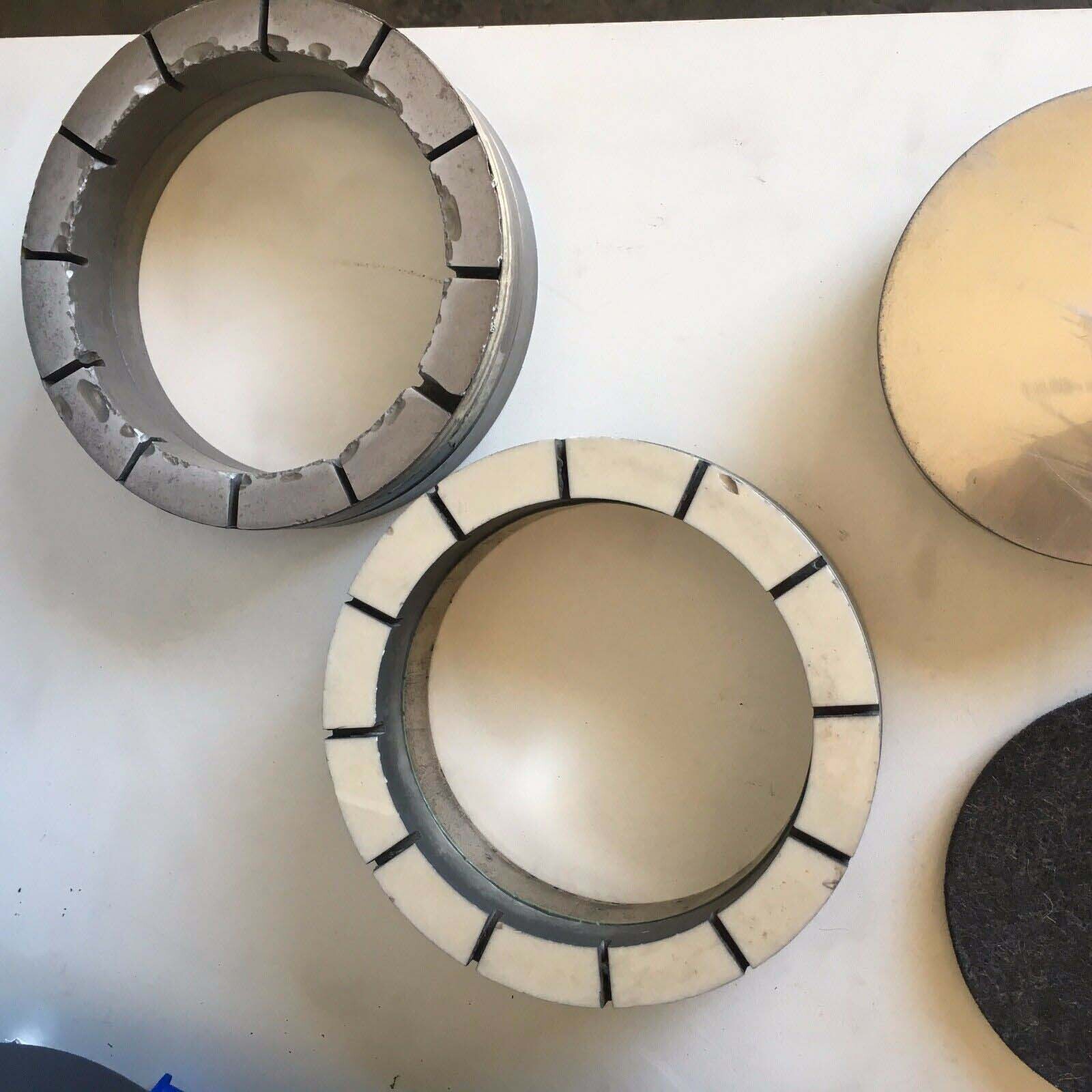

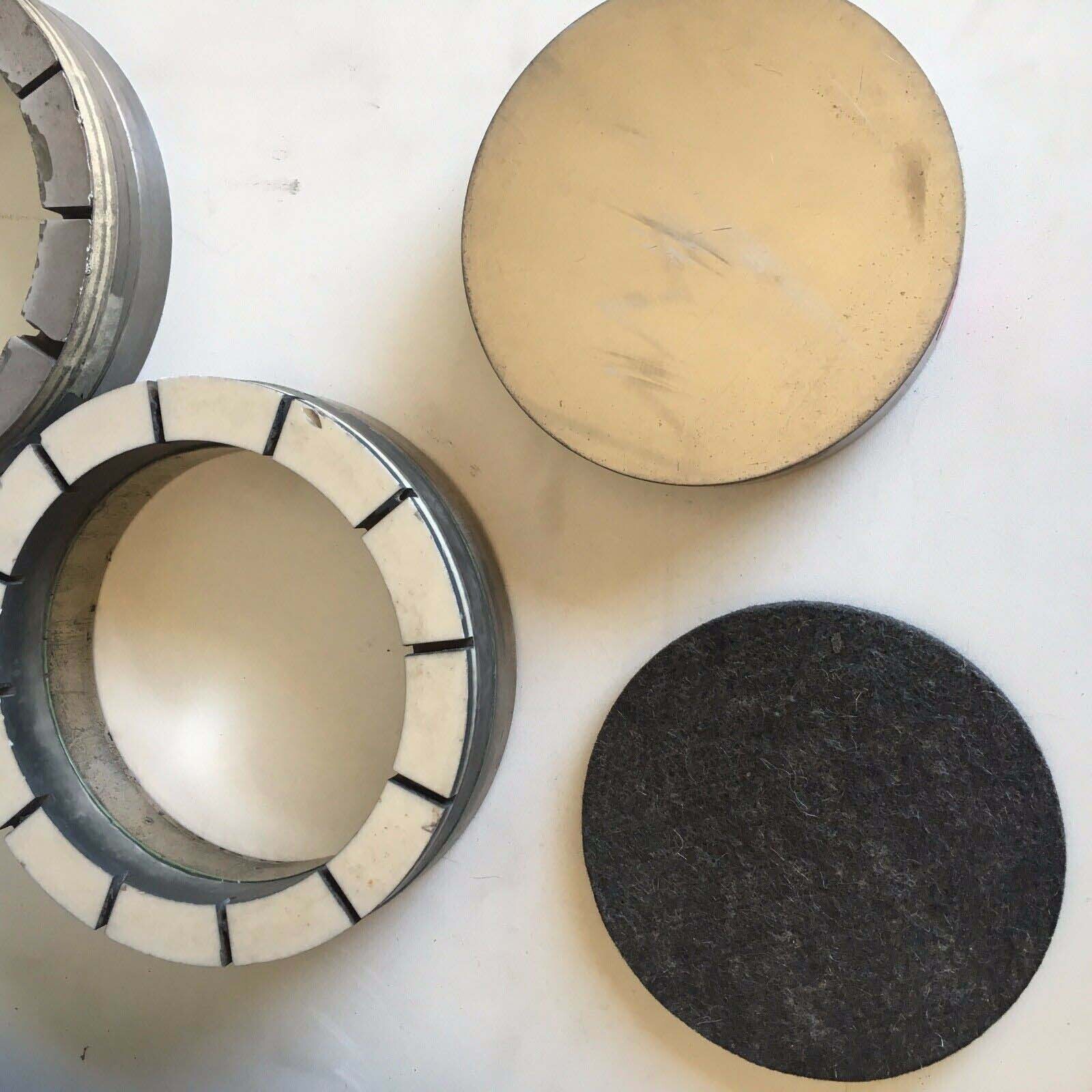

LAPMASTER 15 is a wafer grinding, lapping and polishing equipment that is designed for small to medium sized components such as wafers, semiconductor die, MEMS and optics devices. The system integrates a wide range of unique features such as a double sided rotating drum, a variable speed drive, and an overhead robotic arm. The unit is capable of automatically handling up to 15 individual wafers at a time with minimal operator input. The rotating drum is the core component of LAPMASTER 15 and is designed to enable uniform wide-area grinding, lapping and polishing of components without scratching or leaving surface marks. The drum is driven by a high-torque variable speed drive and is suitable for a wide range of applications. The drum can achieve rotational speeds of up to 3500 RPM with a precision of ±0.2%. The overhead robotic arm is responsible for loading and unloading the wafers from the machine and can be adjusted in height and orientation to accommodate wafers of different sizes and shapes. The arm is capable of moving a single wafer or up to 15 wafers at once, with a precision of ±0.1mm. The arm is also equipped with a laser sensor which monitors and maintains the wafers' position during the lapping and polishing process. As part of LAPMASTER 15 package, a user-friendly software interface is included to adjust the settings and monitor the machine's performance. The software includes a range of predefined parameters and presets for various lapping and polishing operations, which can be further customized by the user. Furthermore, the software can be used to create custom processes and save them for later use. In addition, 15 comes with a complete set of consumables to ensure correct operation and the highest possible quality results. This includes abrasive films, diamond compound, and diamond abrasive strips, which are all designed specifically for use with this machine. All in all, LAPMASTER 15 is an ideal wafer grinding, lapping and polishing solution for small to medium sized components. The tool's combination of features, robust software, and consumables makes it an ideal choice for the precision fabrication of delicate components.

There are no reviews yet