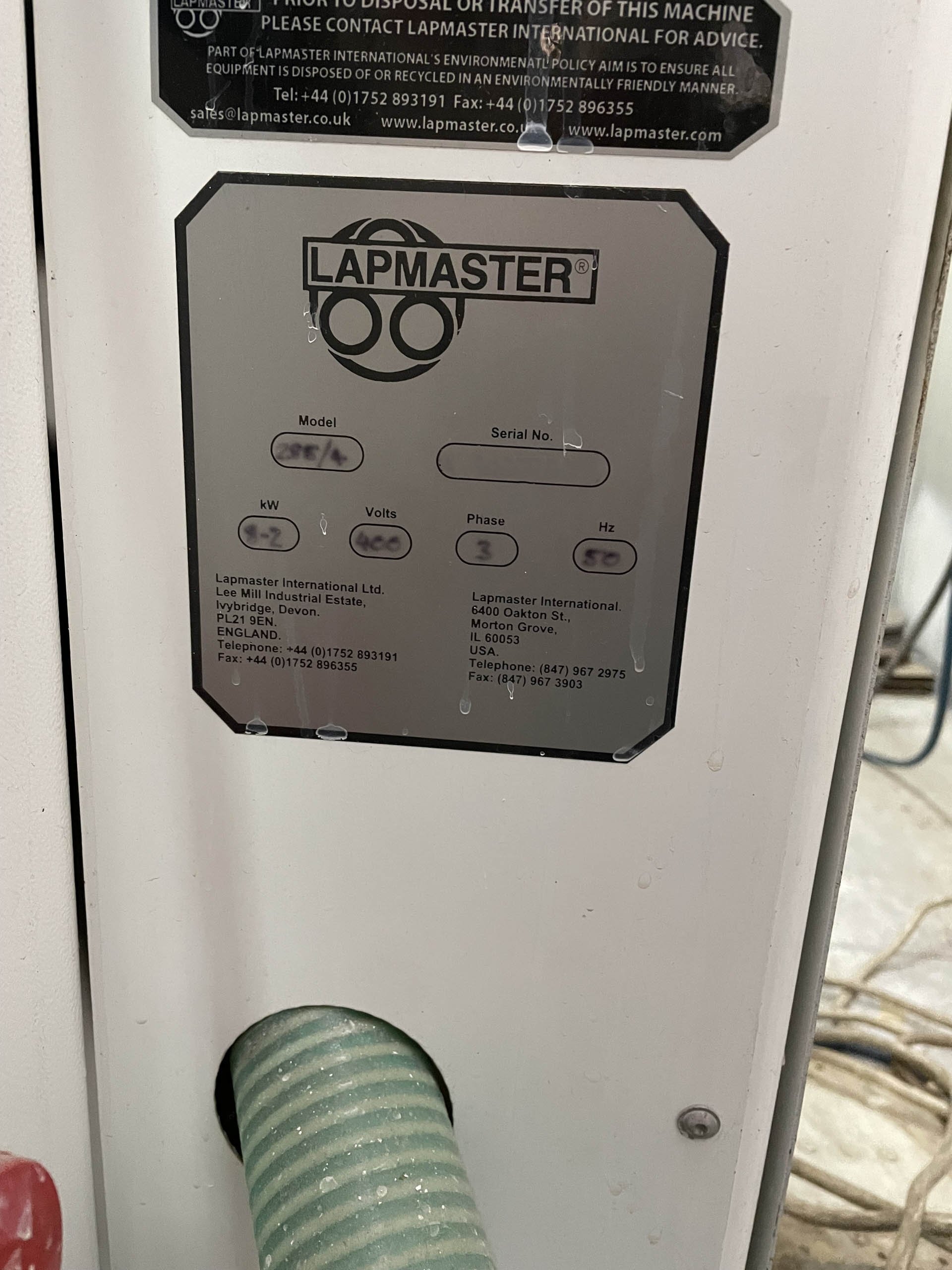

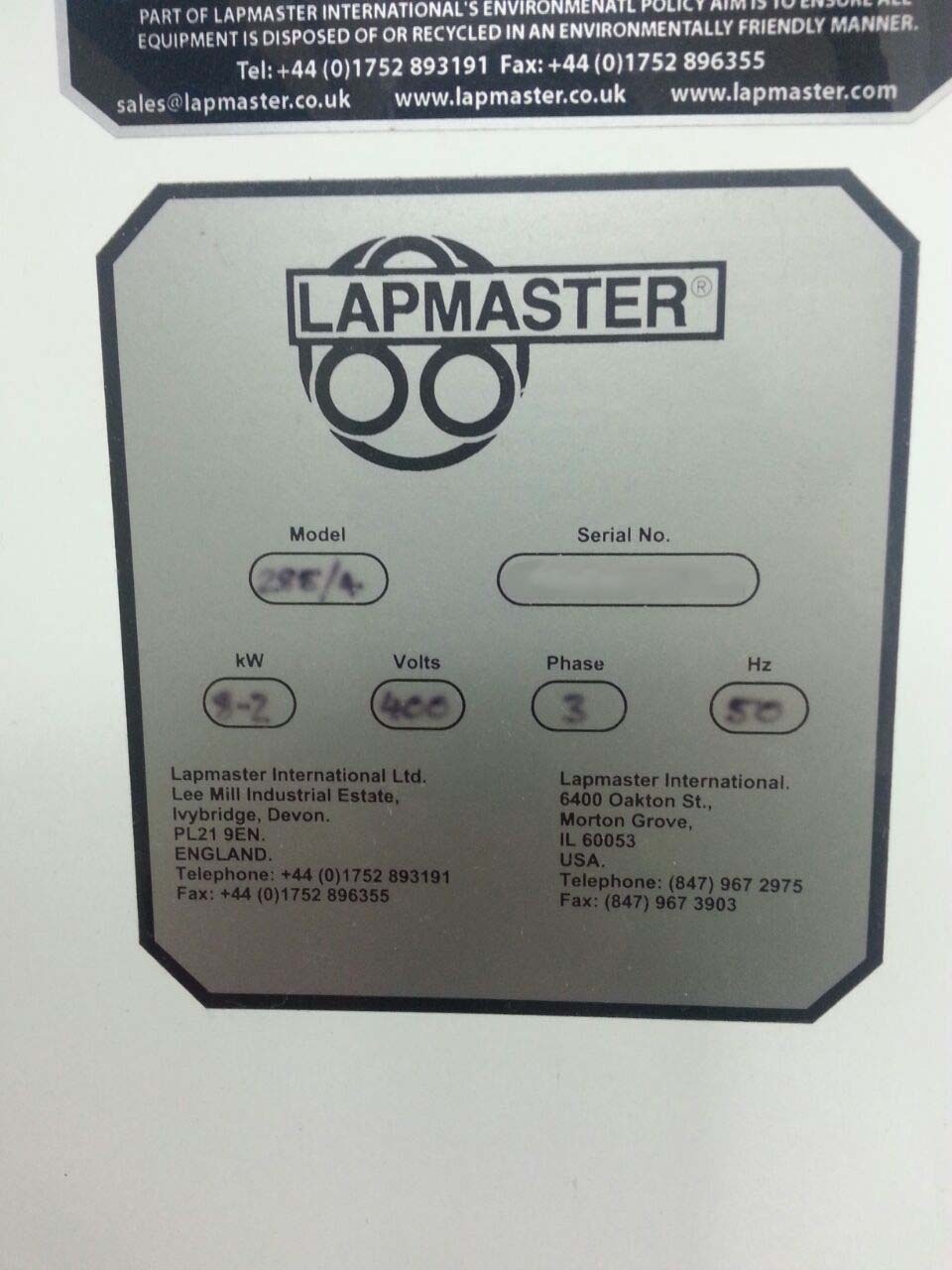

Used LAPMASTER 285/4 #9387801 for sale

URL successfully copied!

Tap to zoom

ID: 9387801

Wafer Size: 24"

Polisher, 24"

Plate size: 610 mm

Correction discs for the plano plates

2006-2007 vintage.

LAPMASTER 285/4 Wafer Grinding, Lapping & Polishing Equipment is a state-of-the-art polishing system used mainly in semiconductor fabrication processes. The unit has two mechanical platforms - a 285mm worktable and an external 4-axis control platform, which can accommodate up to four workpieces at once. It is driven by a 13 amp motor and is enclosed in a housing that is dust-proof and impermeable to fluids. It has a built-in thermal management machine to prevent damage to the workpieces due to excessive heat. LAPMASTER 285 / 4's grinding and lapping procedure begins with a calibrated carrier plate, which is loaded onto the external platform with an adjustable clamping force. This carrier plate houses a fixed grinding wheel and a rotating lapping plate. The force of the clamping can be adjusted by a controller to ensure efficient contact between the workpiece and grinding wheel. With a constant velocity, the grinding and lapping process can be applied on either side of the workpiece. To achieve uniform polishing, 285/4 utilizes a proprietary closed loop tool that locks onto the optical signals emitted by the workpiece. This feedback is used to adjust the speed of the motor to minimize any irregularities in the polishing process. The asset also includes an integrated end-of-cycle detector, which verifies the quality of the wafer's surface to ensure it meets the highest standards. 285 / 4 is also programmable, with up to 500 programmable settings for various applications, such as slotting, drilling, and edge profiling. Its software is also capable of storing up to 1000 recipes for repeatable polishing jobs, optimizing the throughput and saving processing time. Additionally, it can be operated remotely for greater convenience. The model is ideal for precision wafer processing, and is designed to provide the highest quality and repeatability possible. LAPMASTER 285/4 is an efficient and reliable equipment for a variety of applications, making it a top choice for many semiconductor manufacturers.

There are no reviews yet