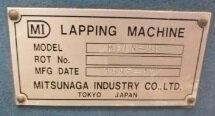

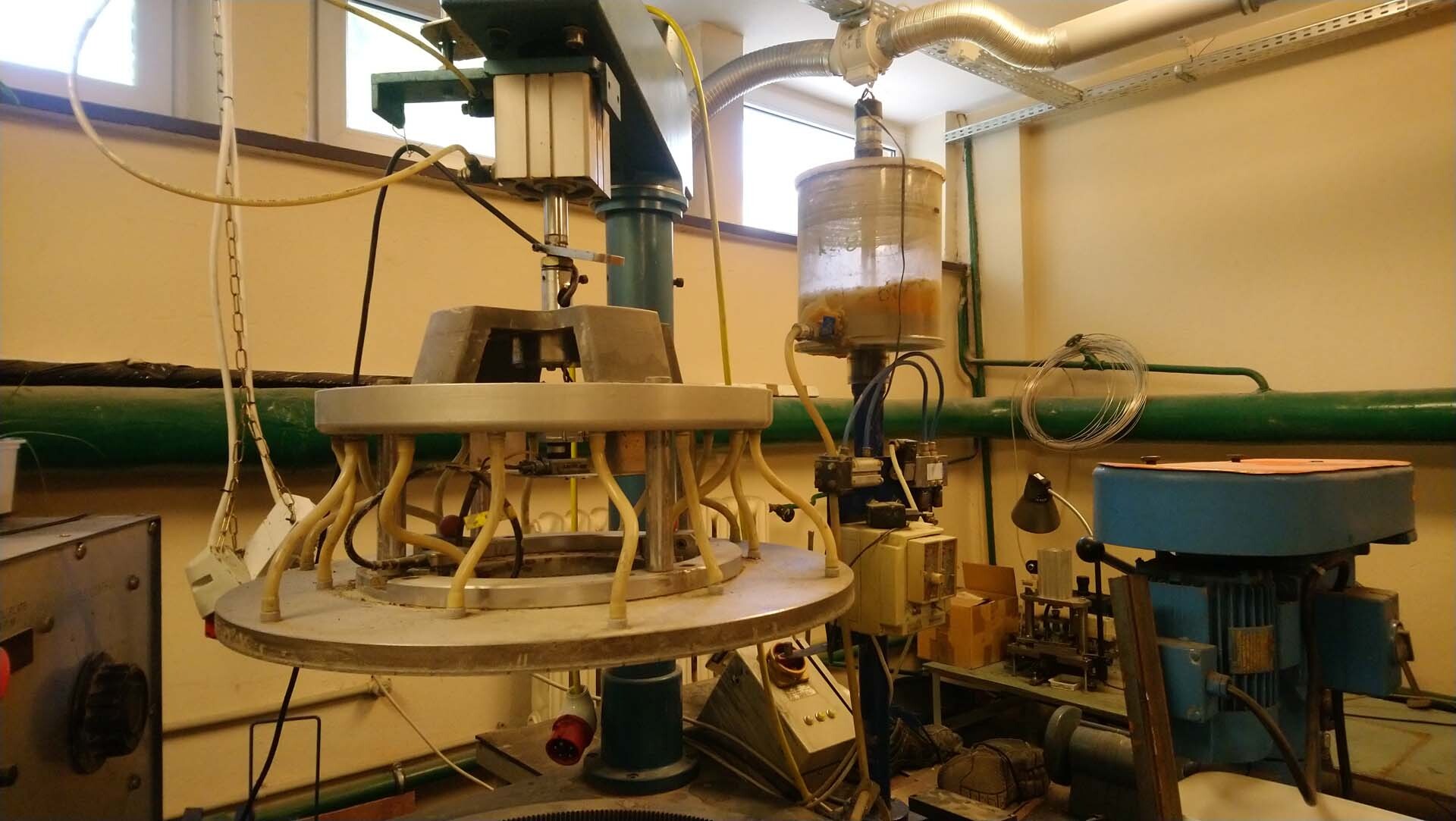

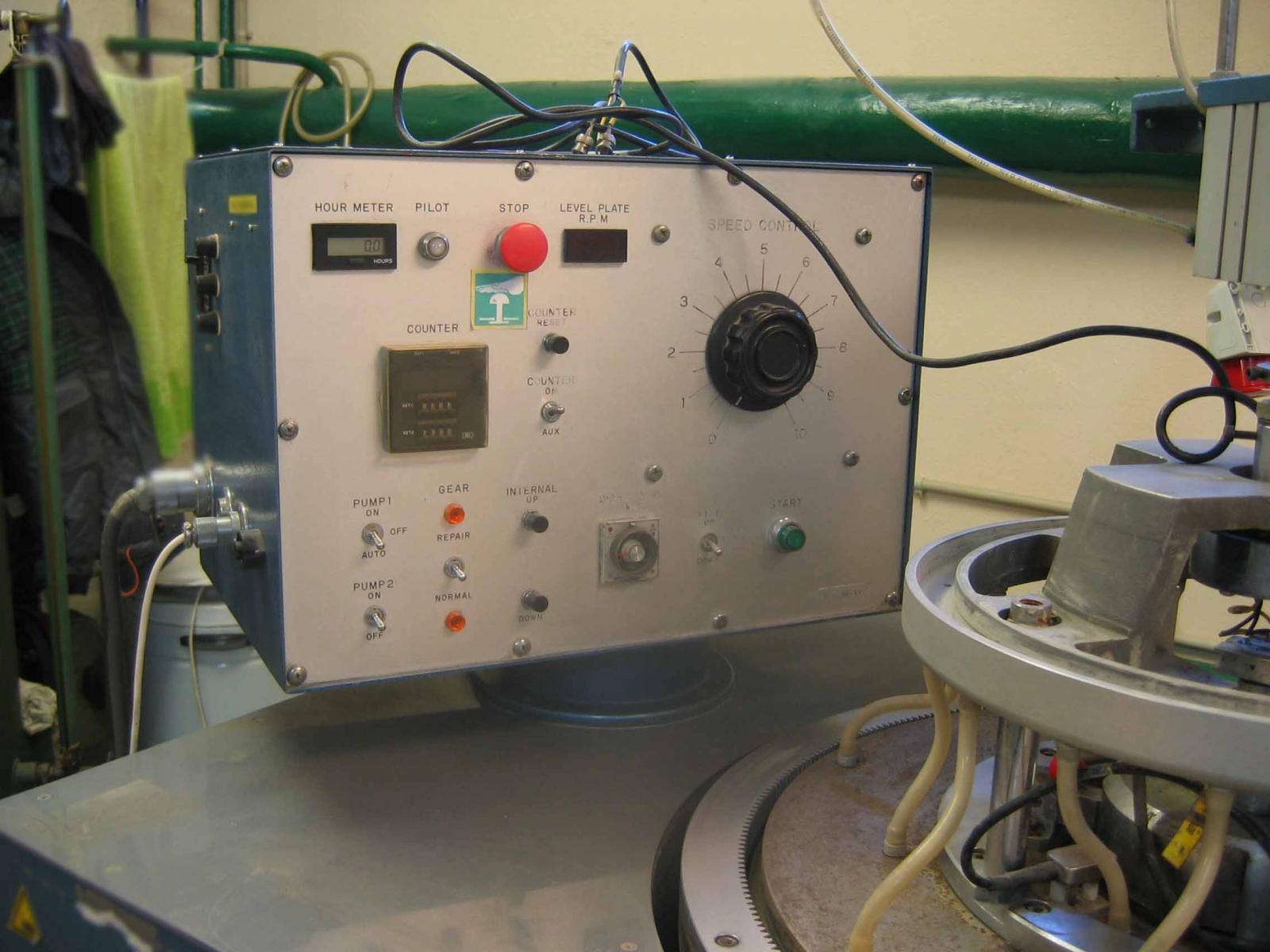

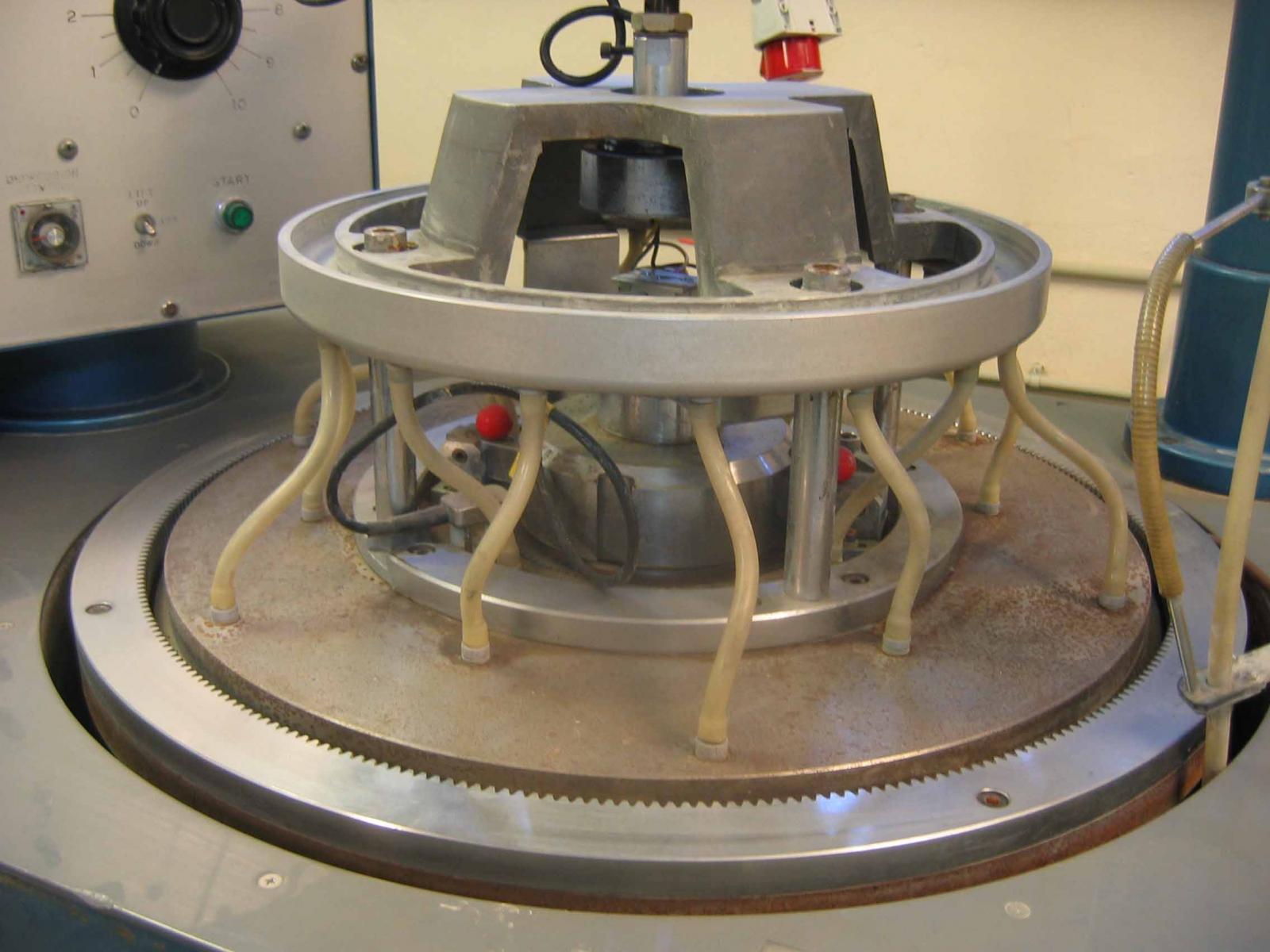

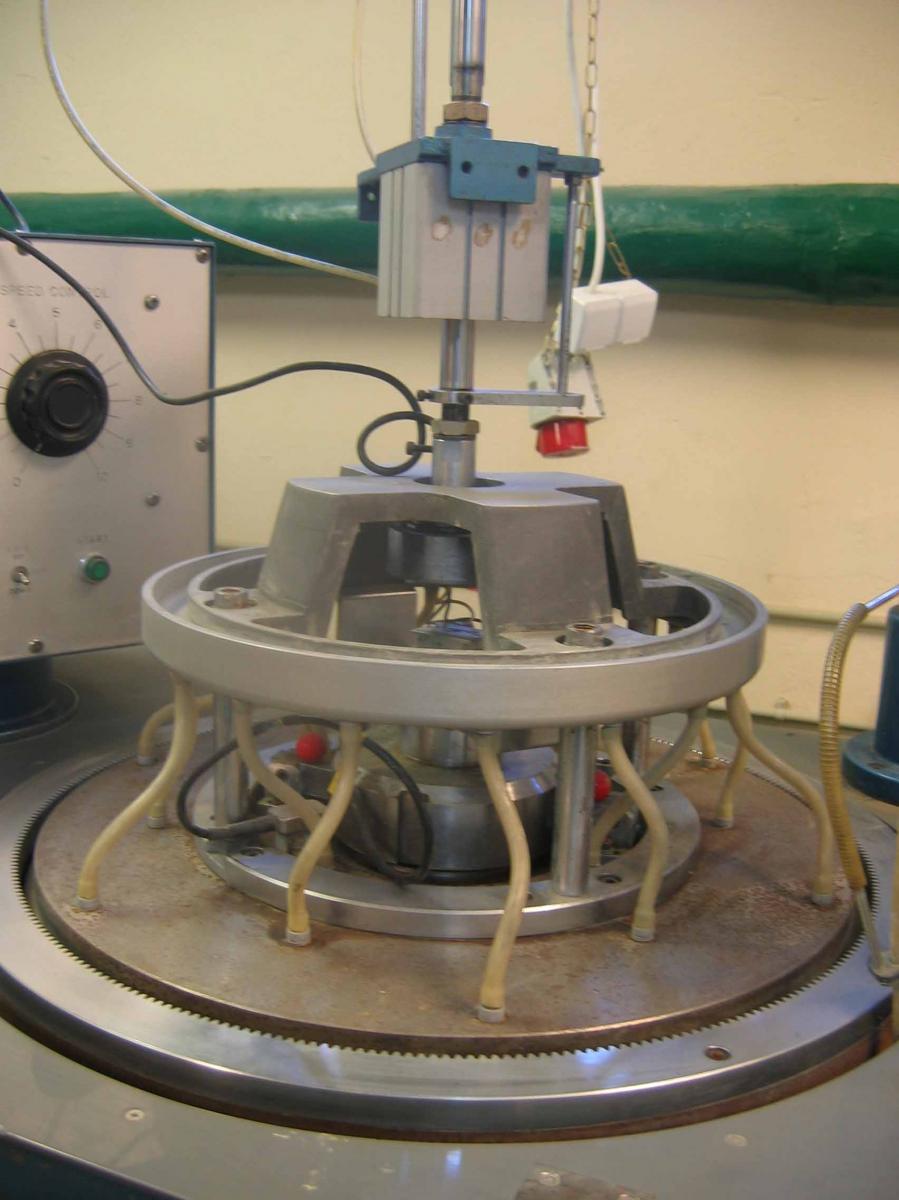

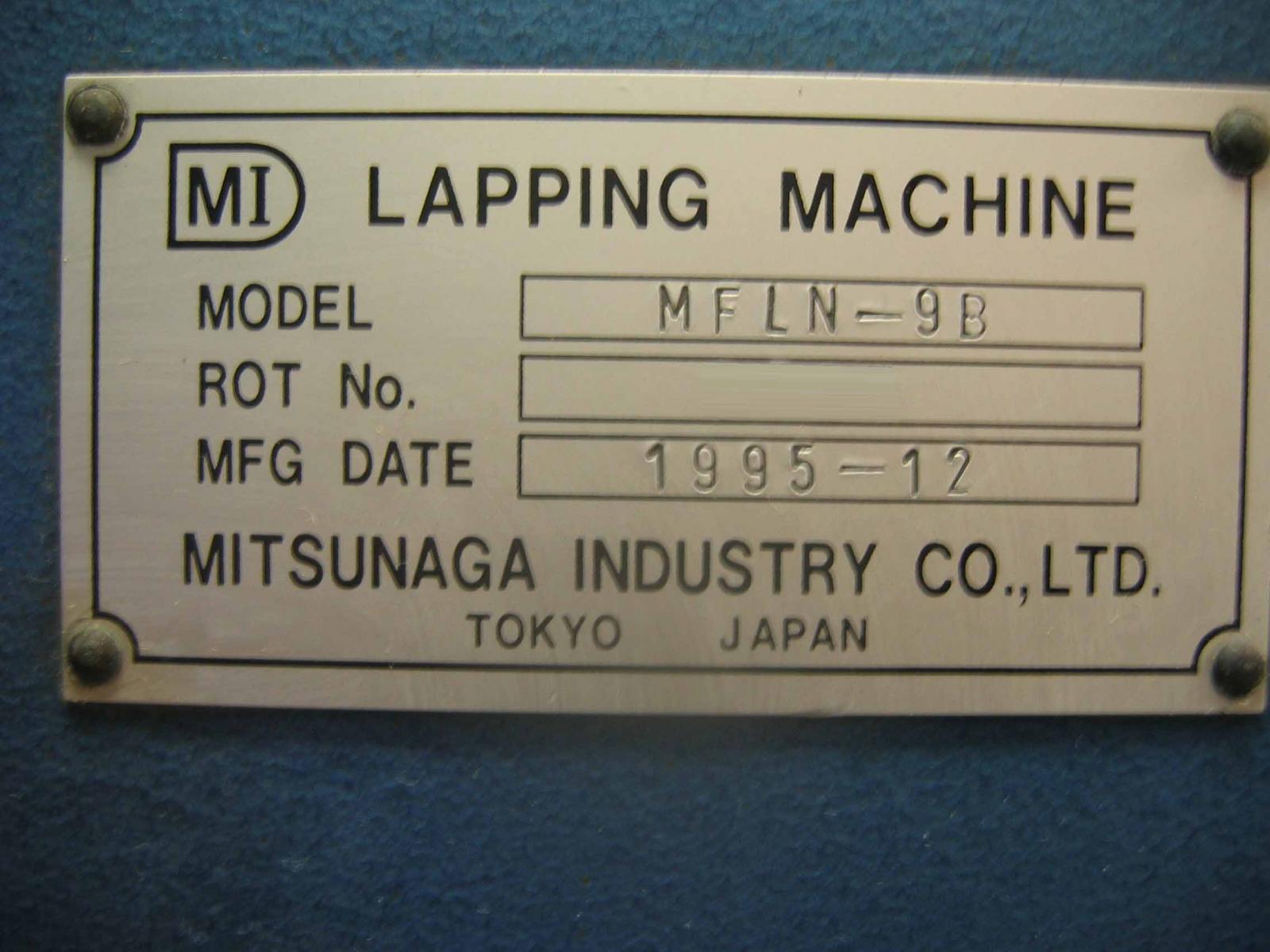

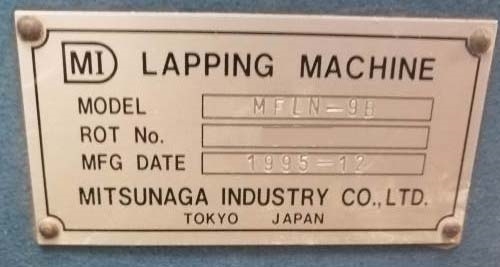

Used MITSUNAGA MFLN-9B #9134432 for sale

URL successfully copied!

Tap to zoom

ID: 9134432

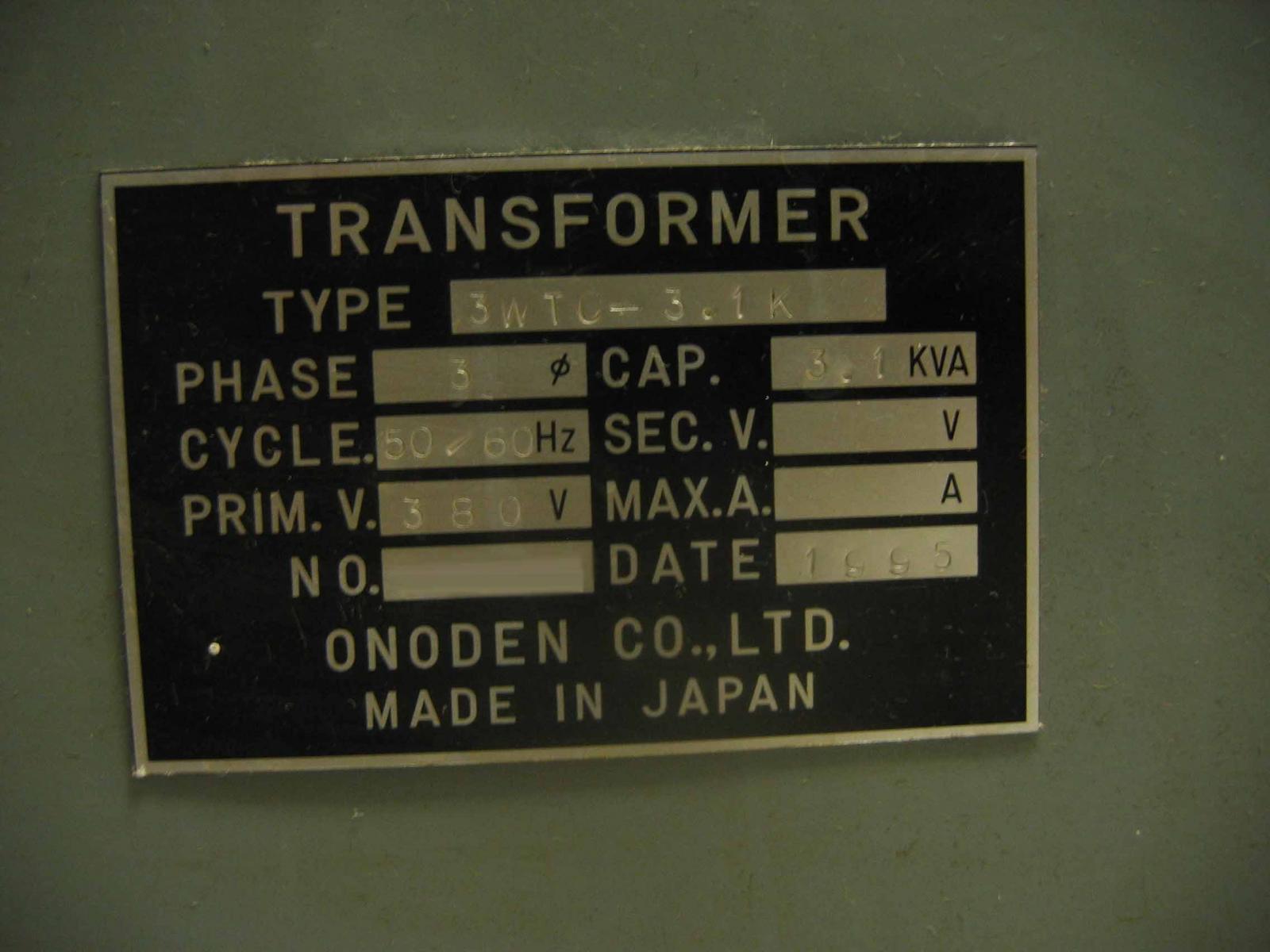

Vintage: 1995

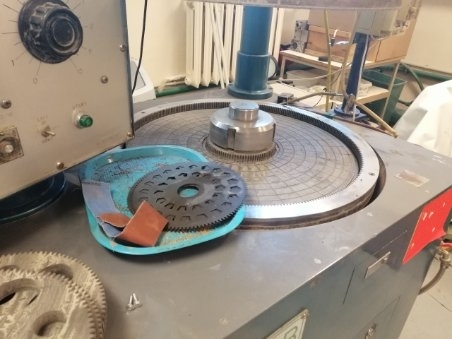

Lapping system

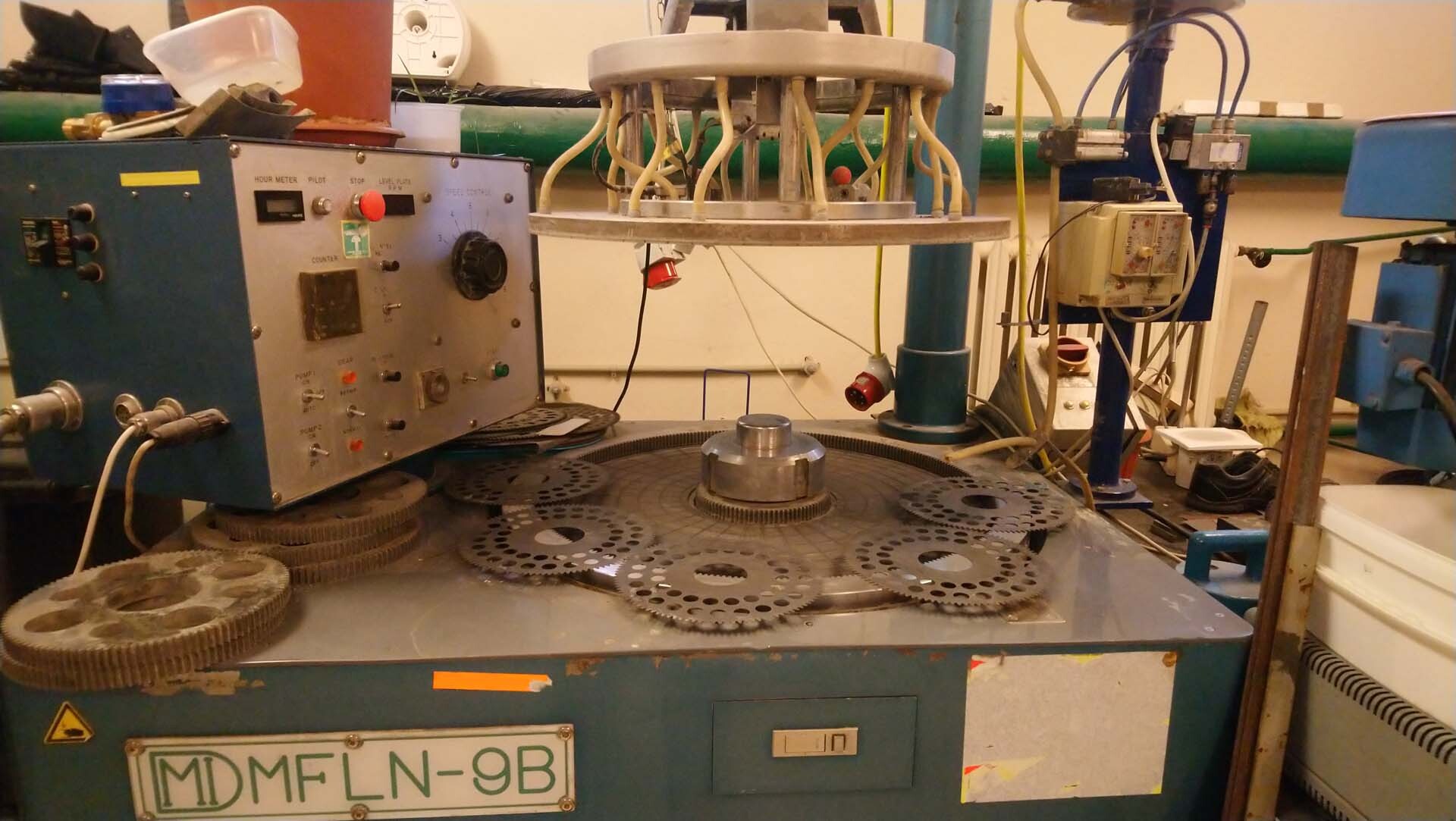

Quartz blank: 16x16 mm or round (14 or 15 mm)

Abrasive: Mostly F600

Cables

Slip ring

Mask size:

Square: 16 mm x 16 mm

Square: 10 mm x 10 mm

Round: 8 mm - 9 mm

Dressing gears

Lapping abrasive supply system

Lapping masks

Does not include:

TRANSAT Measuring system

Mixing unit

1995 vintage.

MITSUNAGA MFLN-9B is a state-of-the-art wafer grinding, lapping and polishing equipment that provides precise and uniform results for a wide range of materials. It can be utilized to process any semiconductor wafer materials including AlGaAs, polysilicon, GeSi and SiC. The system utilizes mechanical stress relief and a variety of grinding, lapping and polishing technologies for wafer surface accuracy and defect-free results. The wafer carrier unit ensures precise motion and mechanical stress relief while the grind head is vertically and horizontally compensated. The machine uses the latest generation of MITSUNAGA Silicon Topside grind process control to deliver repeatable precision surface grinding and lapping results. The tight geometric control on the wafer surface ensures consistent top surface quality. MFLN-9B utilizes a special grind air machine for both top and bottom surfaces of various wafer materials. This air tool controls the grinding force in the form of high-speed air. It also minimizes part to part variability and generates a high-quality surface finish. The asset also features a polishing stage for post-grinding processing. It utilizes a vacuum chuck polisher for defect-free polishing of the top surface. The polishing parameters such as airflow, chuck speed, head pressure, spindle speed, and process time can be adjusted to custom-configure the polishing result. The control model also monitors the polishing process and the production environment in real-time. Overall, MITSUNAGA MFLN-9B is an advanced wafer grinding, lapping and polishing equipment that provides consistently high results in the production environment. Its grind air system and vacuum chuck polisher ensure precision top surface quality and defect-free results. The unit is capable of performing a variety of processes and adjustments to customize the polishing output. It is a reliable and efficient machine for processing all semiconductor wafer materials.

There are no reviews yet