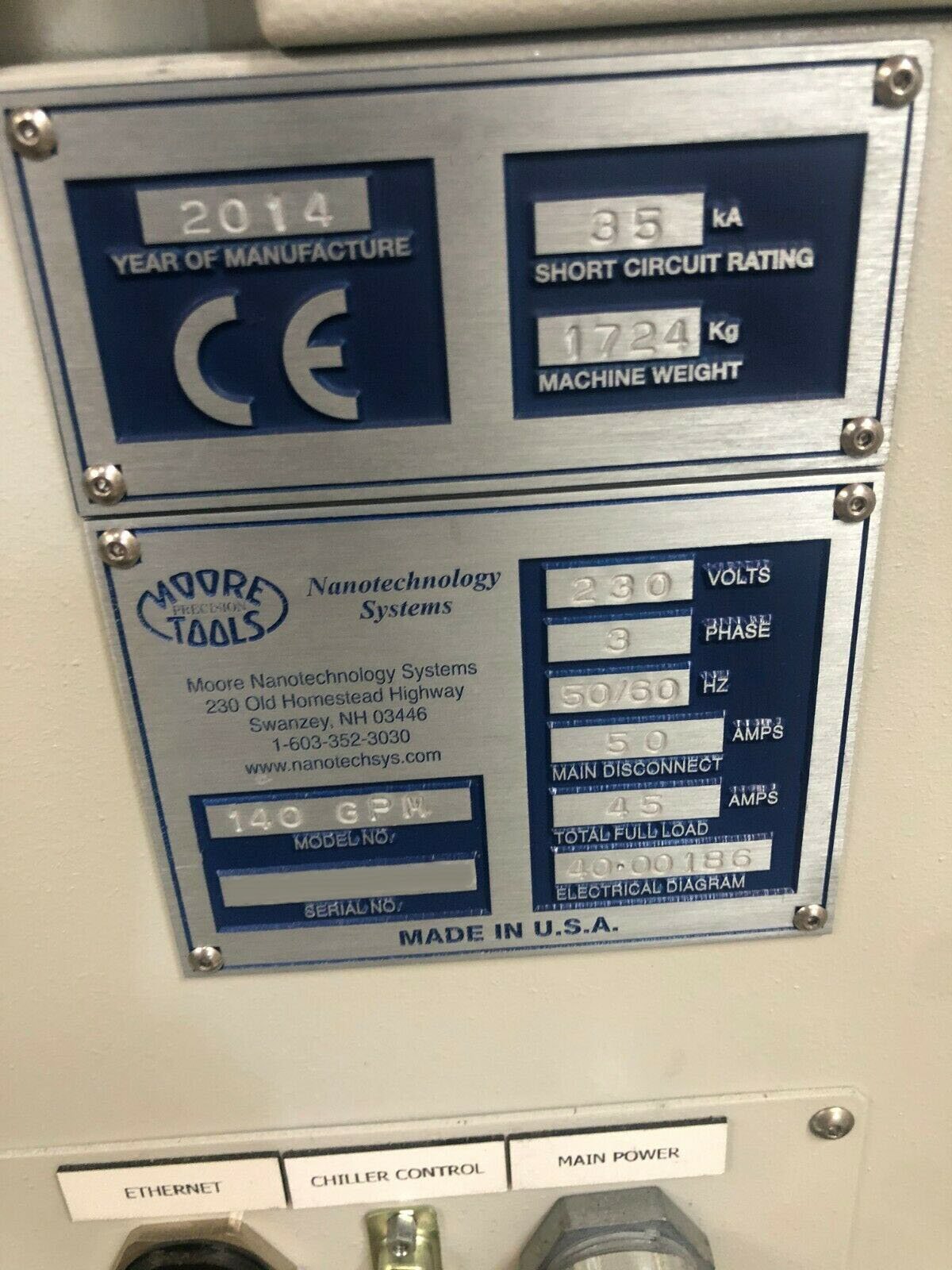

Used NANOTECH 140GPM #9312859 for sale

URL successfully copied!

Tap to zoom

ID: 9312859

Vintage: 2014

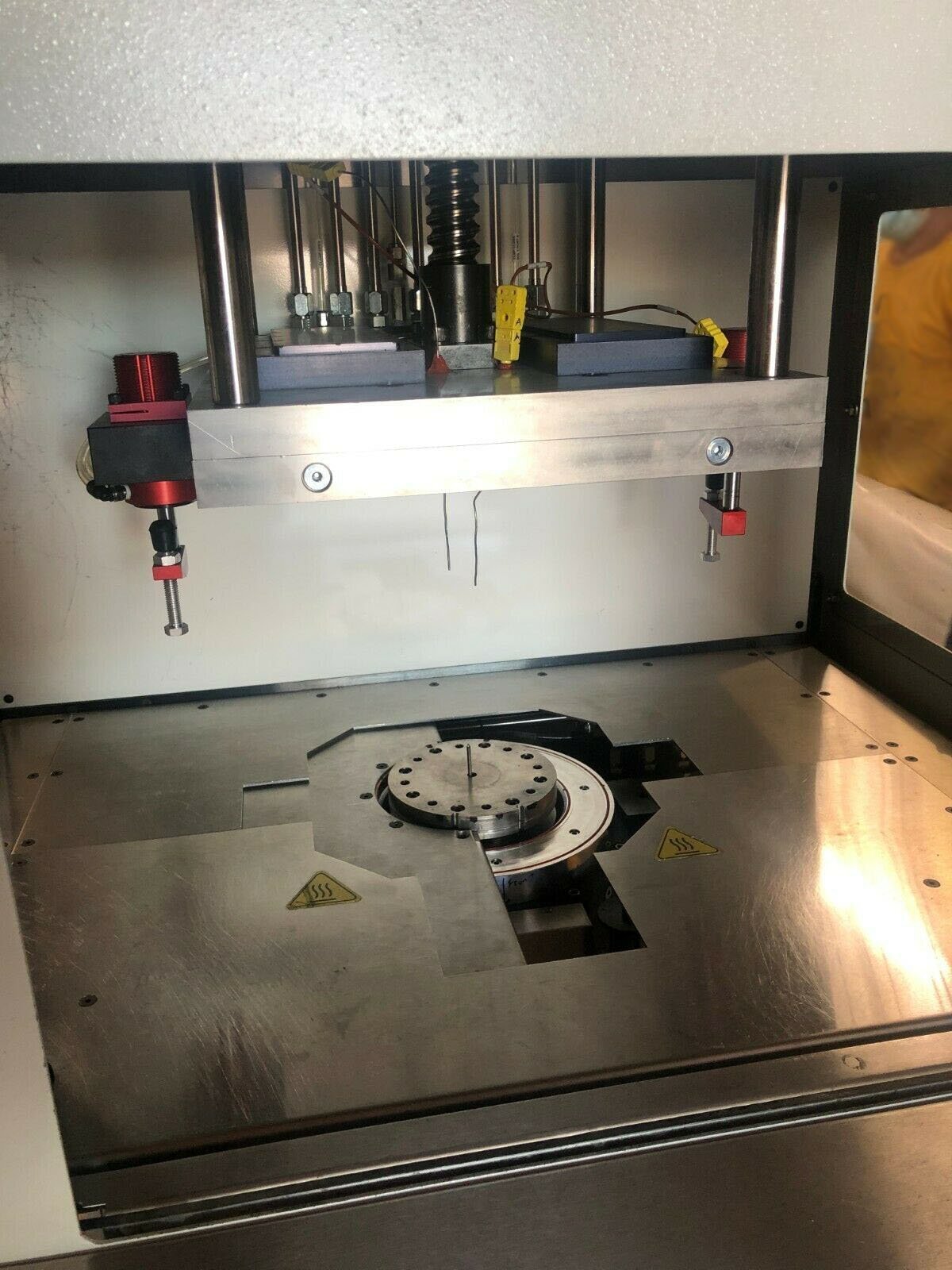

Glass press molding system

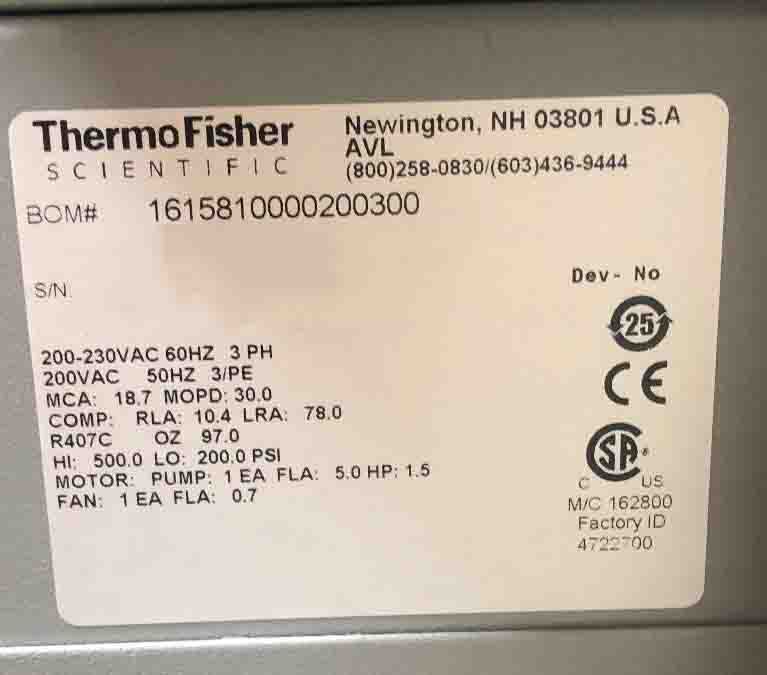

With NESLAB ThermoFlex 10000 Chiller

2014 vintage.

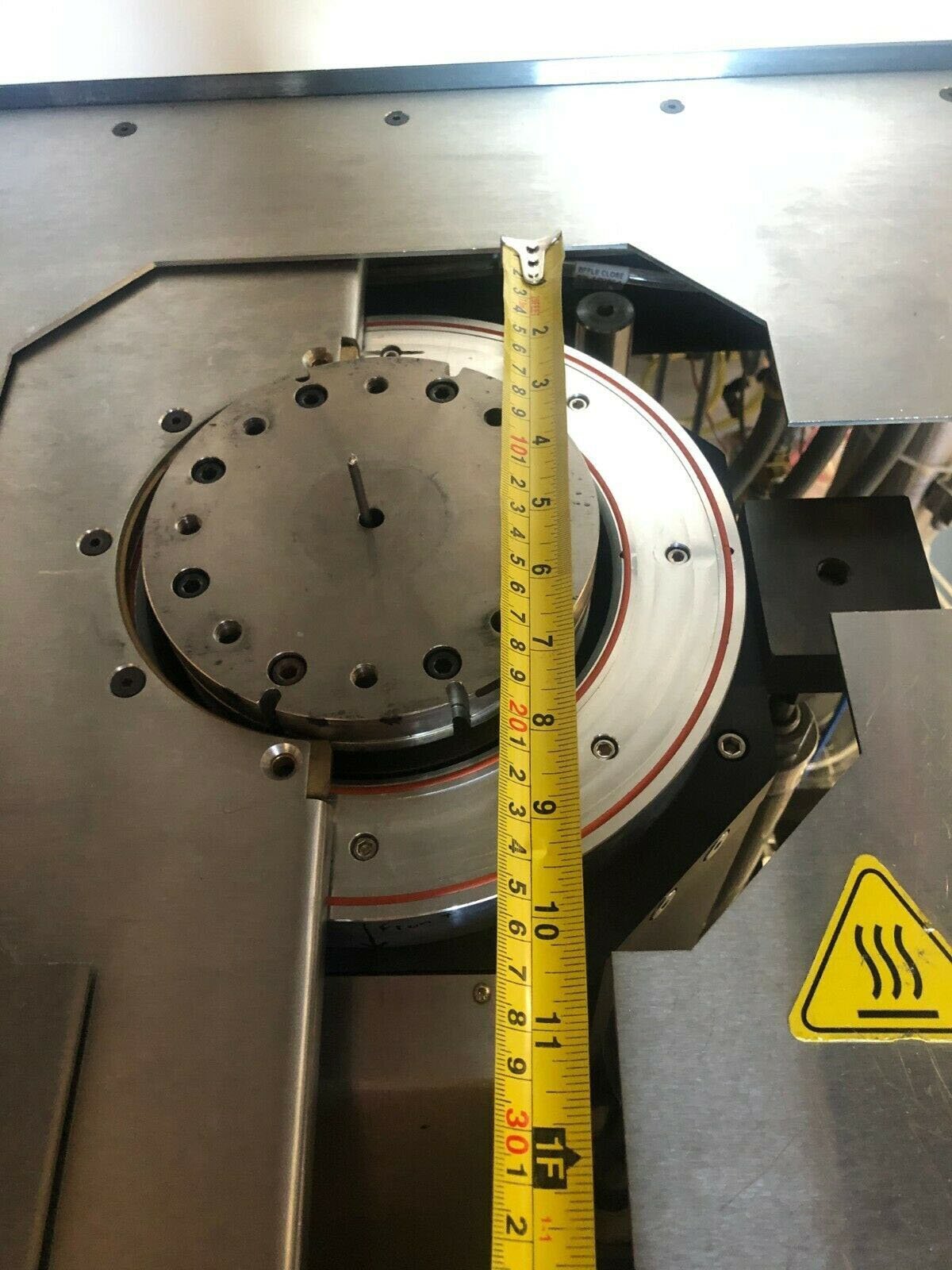

NANOTECH 140GPM Wafer Grinding, Lapping & Polishing Equipment is a compact, high-precision device used for accurately grinding, lapping, and polishing substrates to a surface finish with superior flatness, step height control, and superior surface quality for a range of wafer sizes up to 152 mm. The system is also equpped with an intuitive auto-adjusting grinding head which can be programmed to automatically adjust its grinding pressure for different thicknesses, providing an optimal grinding and polishing process in a single step. 140GPM consists of a multi-axis diamond tool, a high-speed spindle motor, and synchronized rotation and oscillation axes with a high-resolution encoder and positioning accuracy of 5 arc seconds. This allows for precise micro-lapping of the wafer with minimal tool wear. With a maximum speed of 28,000rpm in X&Y, NANOTECH 140GPM is able to achieve the best surface finish at the highest speed. The unit also features an air bearing that enables low temperatures operation, which is ideal for achieving a precise wafer grind. 140GPM provides an advanced water-cooled configuration with industrial-grade filters to effectively maintain a maximum temperature of 40°C and keep the process temperature stable throughout the entire process. Furthermore, the wafer handling machine features a dedicated parallel handling mechanism designed to automatically load and unload wafers, as well as a pick and place mechanism for precise positioning. NANOTECH 140GPM utilizes a high-precision in-line metrology tool which measures the process parameters in real-time. This metrology asset is used to monitor the eigenvalues of the lapping process in order to ensure proper process control and accuracy. Additionally, an off-line measurement model allows for the surface finish and flatness of the wafer to be measured accurately and quickly. Finally, 140GPM is equipped with a user-friendly graphical interface for controlling the entire process. This provides a simple way to set up the equipment and adjust the grind parameters according to the size of the wafer and its desired surface finish. The control system also allows for data storage capabilities in order to maintain a traceable record of the entire lapping and polishing process.

There are no reviews yet