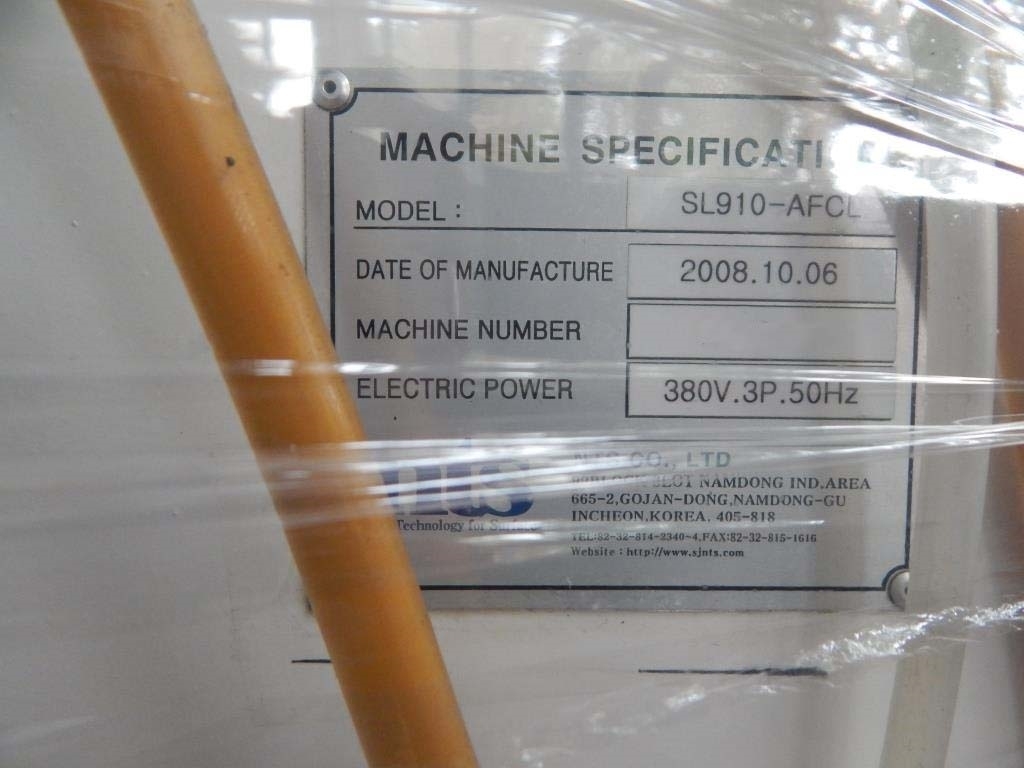

Used NTS Nano Surface SL910-AFCL #9226058 for sale

URL successfully copied!

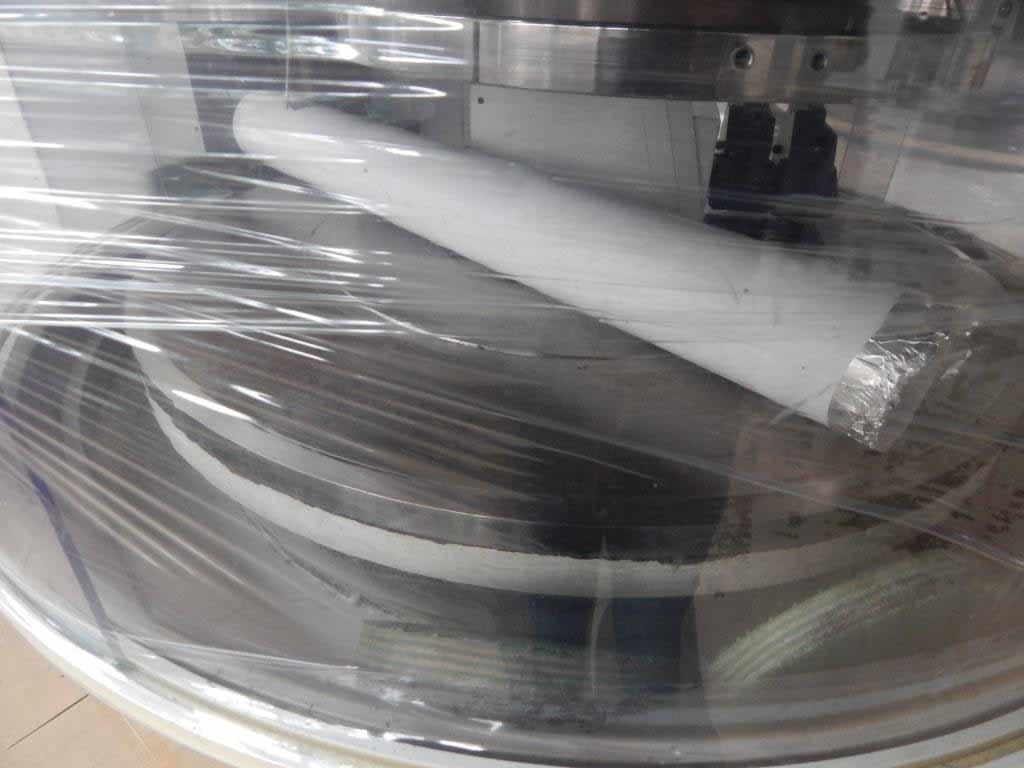

Tap to zoom

ID: 9226058

Vintage: 2008

Single diamond polishing system

Polishing heads

Plate non step variable speed system: Smooth start / Stop feature

(4) Holder type pneumatic pressure systems / Level type

Real-time control temperature

Automatic diamond slurry spray system: 2 Points

4-Axes pressure plate water cooling system

(2) Pneumatic step pressure systems: Cylinder ф80 x 200 st

Machine emergency auto-stop function

Hume protective / Exhaust system

Spindle housing system

Lapping plate water cooling system

IR Temperature reading system

Pressure plate: ф360 (Sus 304)

Drop slurry supply system

Timer (Process time)

Solid frame structure

Hand shower: 2 Spots

(2) Auto stirrers

(2) Spray nozzles

Plate: 15~80 RPM

Semi-automatic:

Precision lapping plate facing and grooving system

One time grooving: 150 um Deeps

Main motor: 220 V, 50/60 Hz, 3 Phase, 7.5 kW

Input voltage: 220 V, 50/60 Hz, 3 Phase

2008 vintage.

NTS Nano Surface SL910-AFCL is a wafer grinding, lapping, and polishing equipment designed by NTS for automation of grinding, lapping, and polishing of wafers in a cost-efficient and repeatable manner. This system is designed to prepare wafers for advanced semiconductor applications, helping to reduce cycle times and improve yields. The SL910-AFCL is powered by a high-performance, fan-cooled, electric motor that is capable of producing up to 24 kW of power. It features Rapid Convergence Grinding Technology (RCGT), with at-speed pattern matching for fast and efficient grinds. An onboard PC-based unit features a real-time adapted oscillator that is capable of optimizing the controlling of the grinding and polishing processes. Additionally, it is equipped with an integrated lapping film machine that allows for integration of different lapping films, to allow for further process optimization. Benefits of the SL910-AFCL include several precision control options, including levels, angles, and complex multi-step processes, as well as a bunch of advanced automation capabilities such as loadlocker, refelex, and wafer-thinning. Moreover, it is also capable of achieving sub-2 nm surface finish results. The tool offers tight process control and repeatability that delivers high yields for volume production, as well as enables users to take fewer steps in their process. In order to maximize throughput and minimize cost, the SL910-AFCL is fitted with adjustable speed and temperature preset to optimize the wafer leveling and polishing sequence. Furthermore, it features an autobalancer asset for dynamically maintaining the pressure and force level, and a motorized Platen Lift and Air Lift for automatic lifting and lowering of the wafer chucks for a more efficient and faster level and polish process. It has an available auto-wafer memory holding model, enabling the machine to remember the polish levels of the wafers and providing an accurate recall for a faster sub-sequent process. Overall, Nano Surface SL910-AFCL is a powerful, advanced, and cost-effective wafer grinding, lapping, and polishing equipment that enables users to improve their process yield and reduce cycle times.

There are no reviews yet