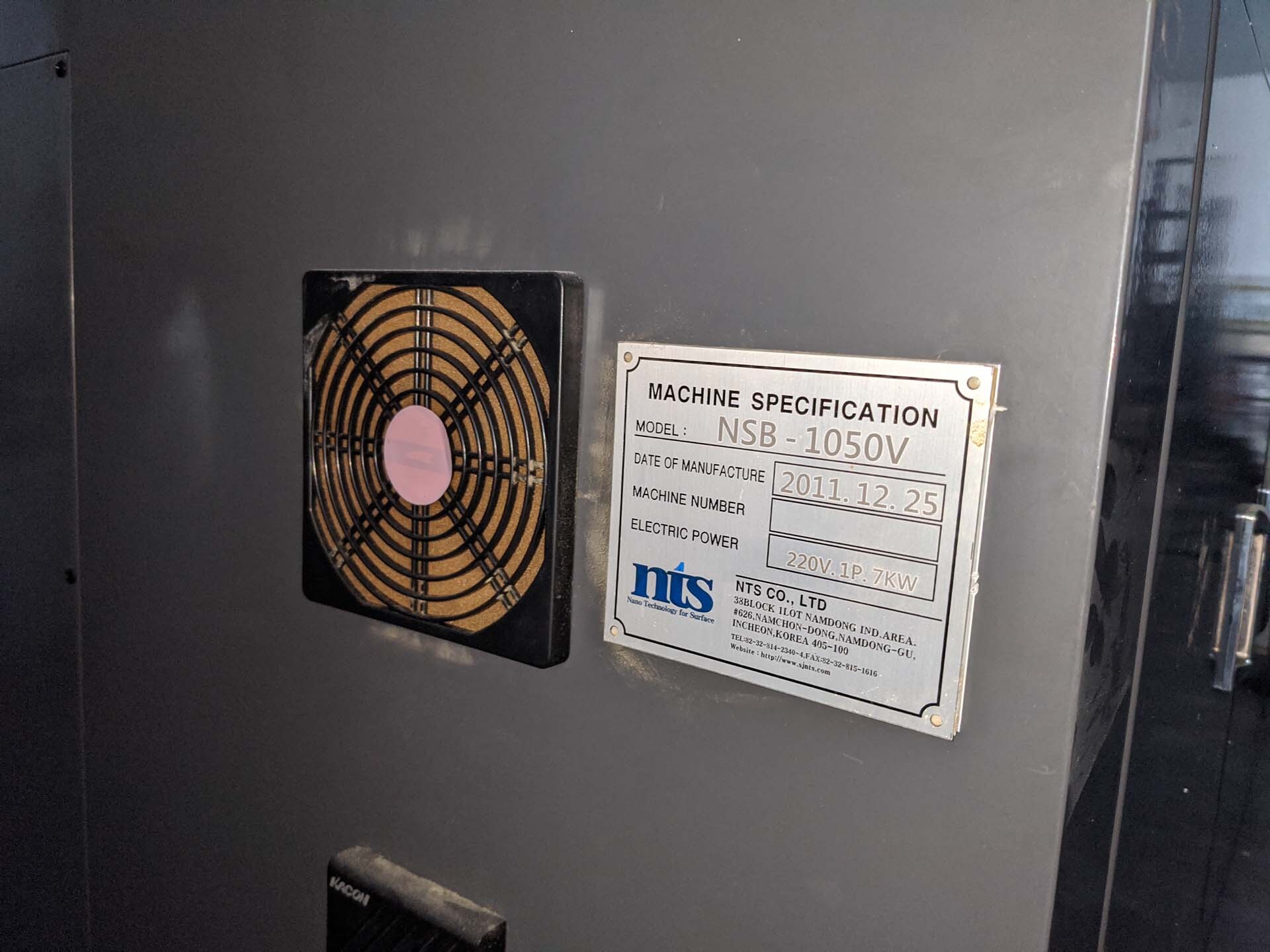

Used NTS NSB-1050V #293608628 for sale

URL successfully copied!

Tap to zoom

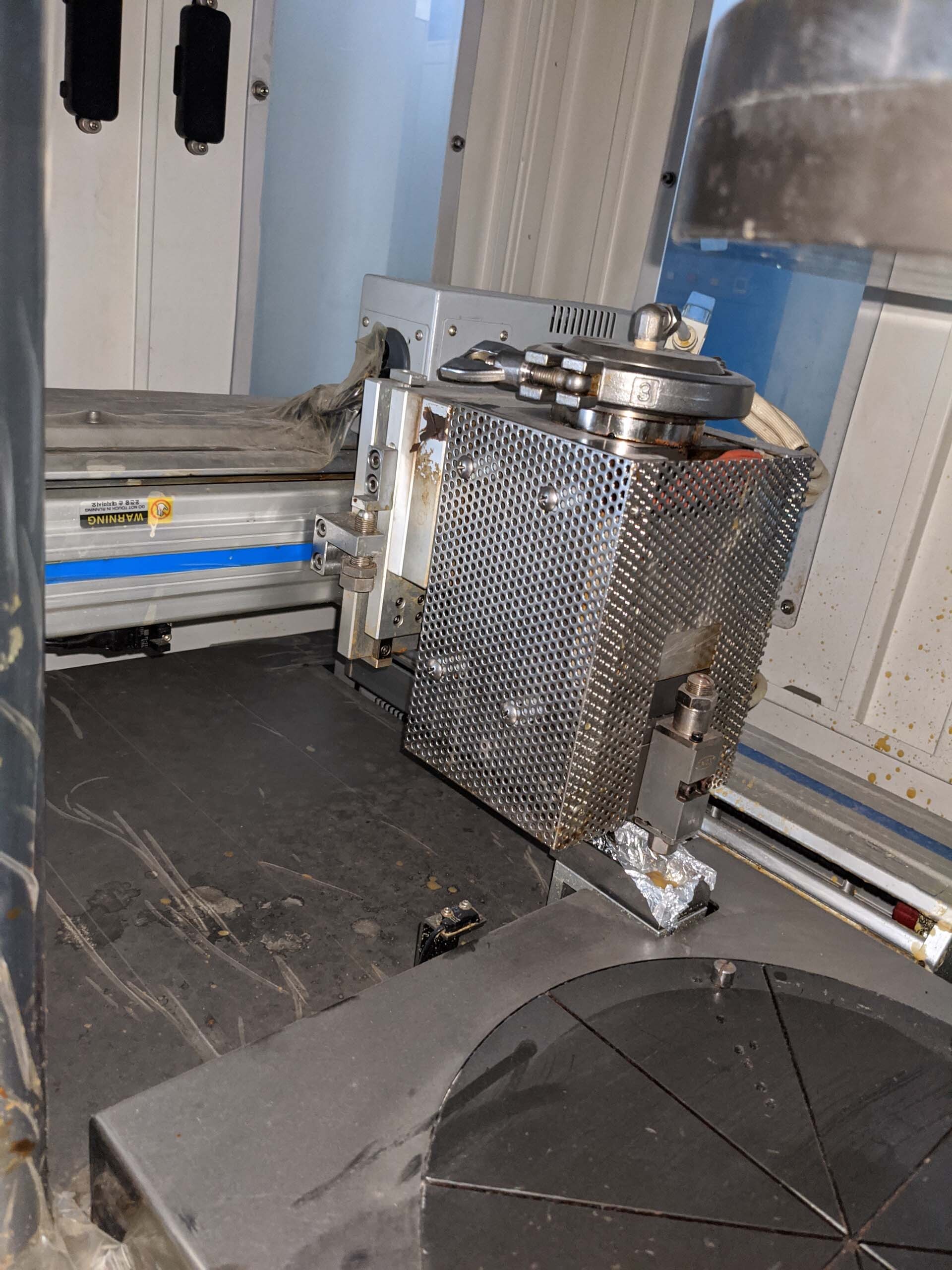

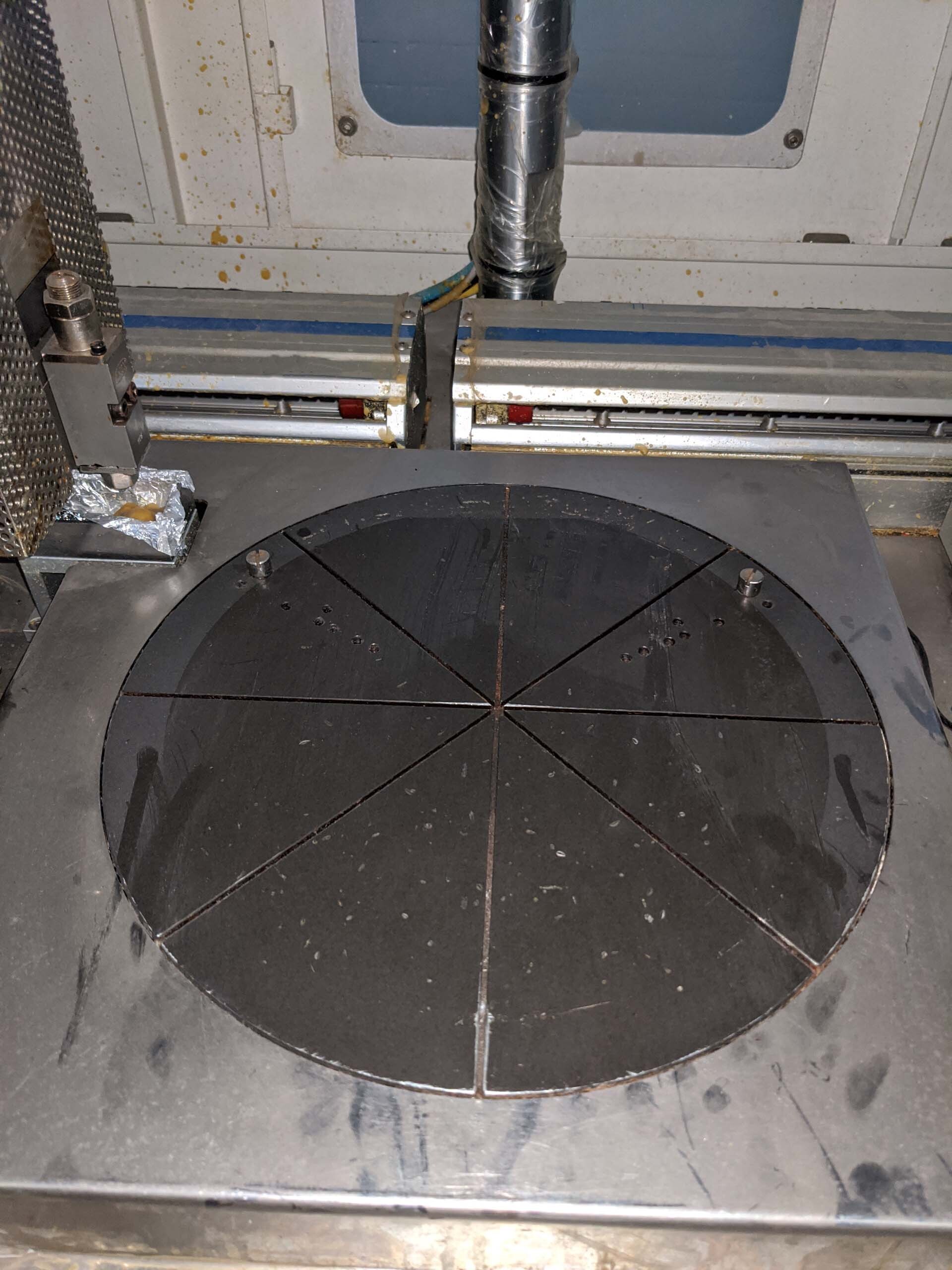

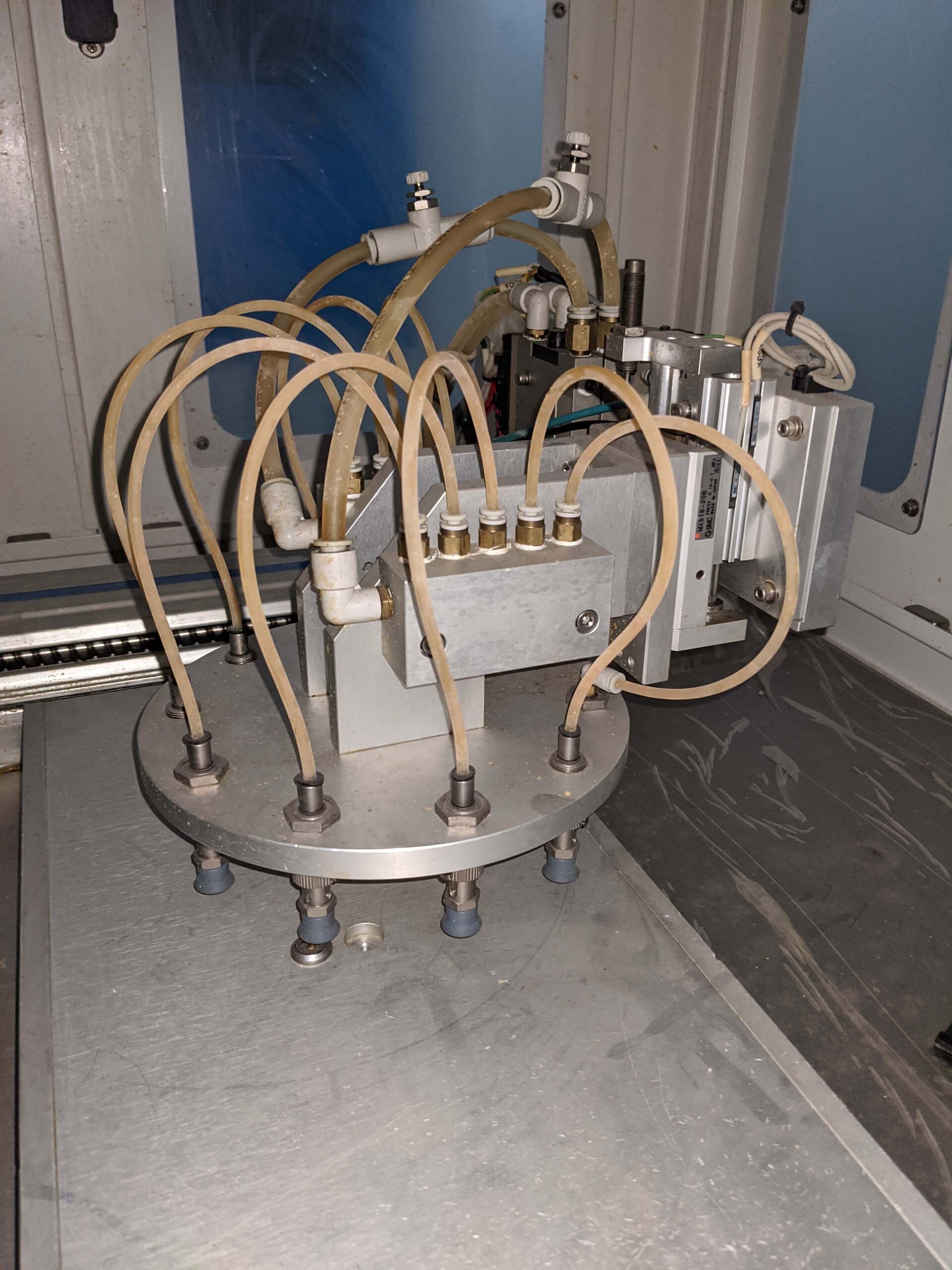

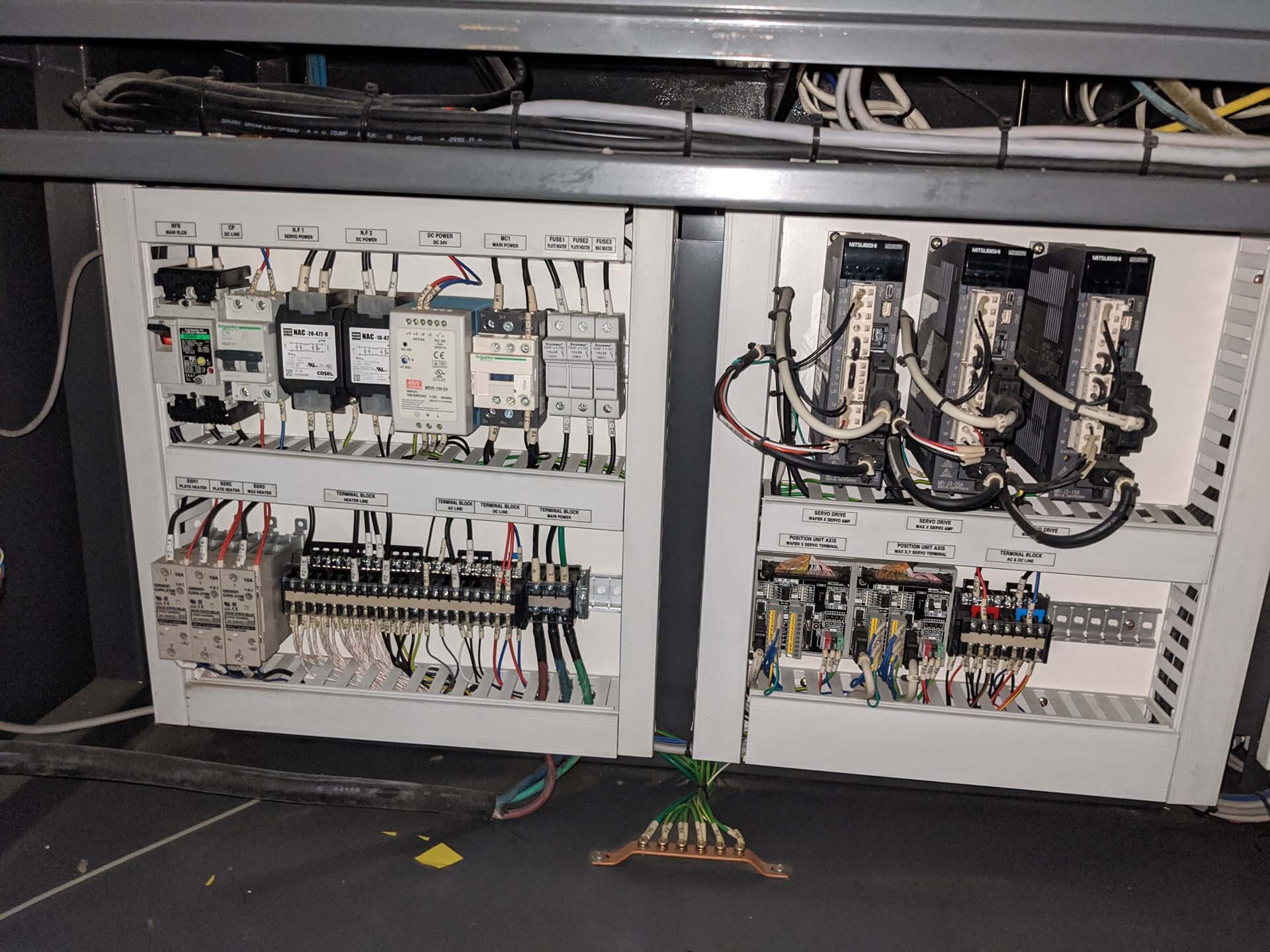

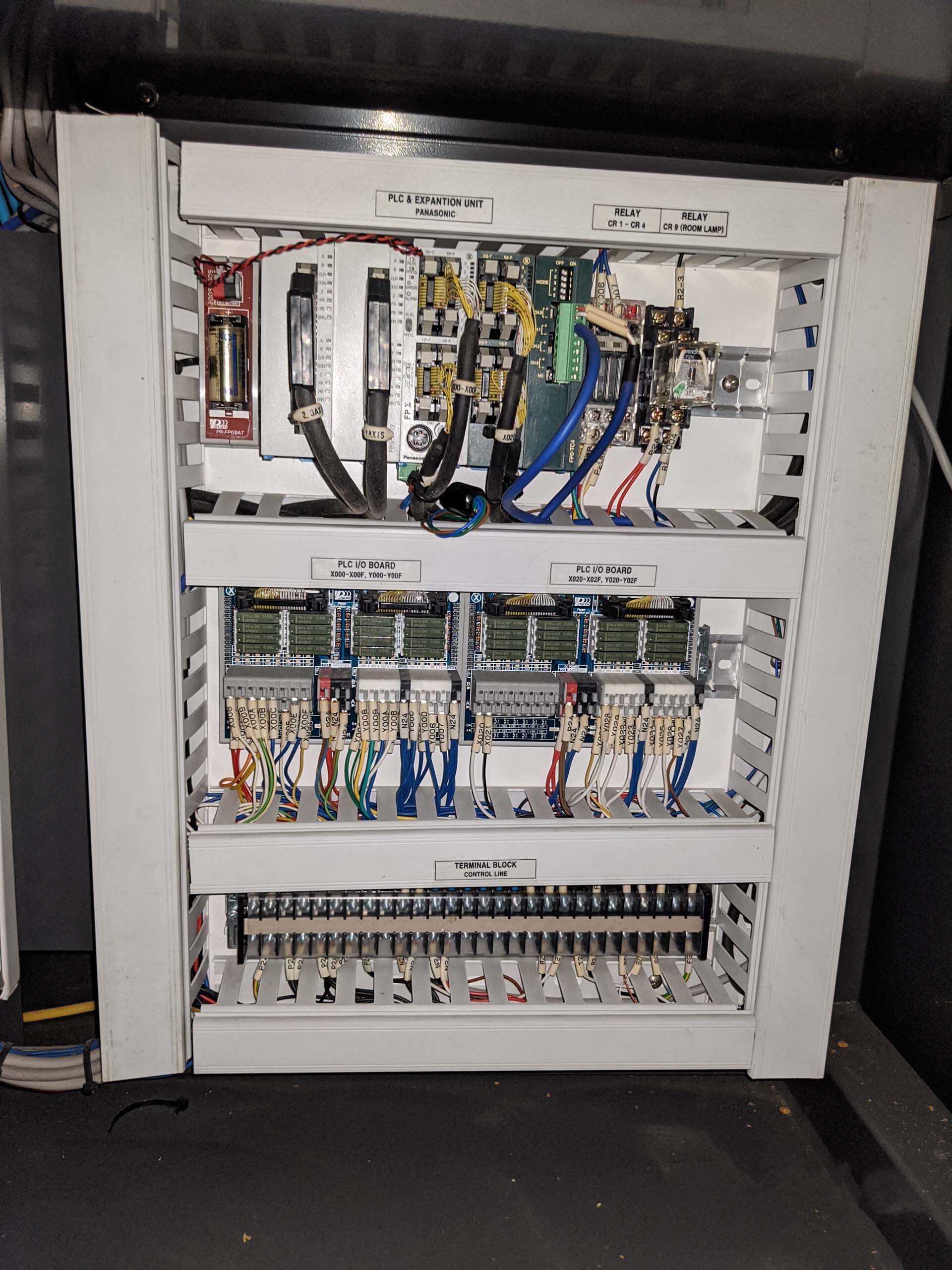

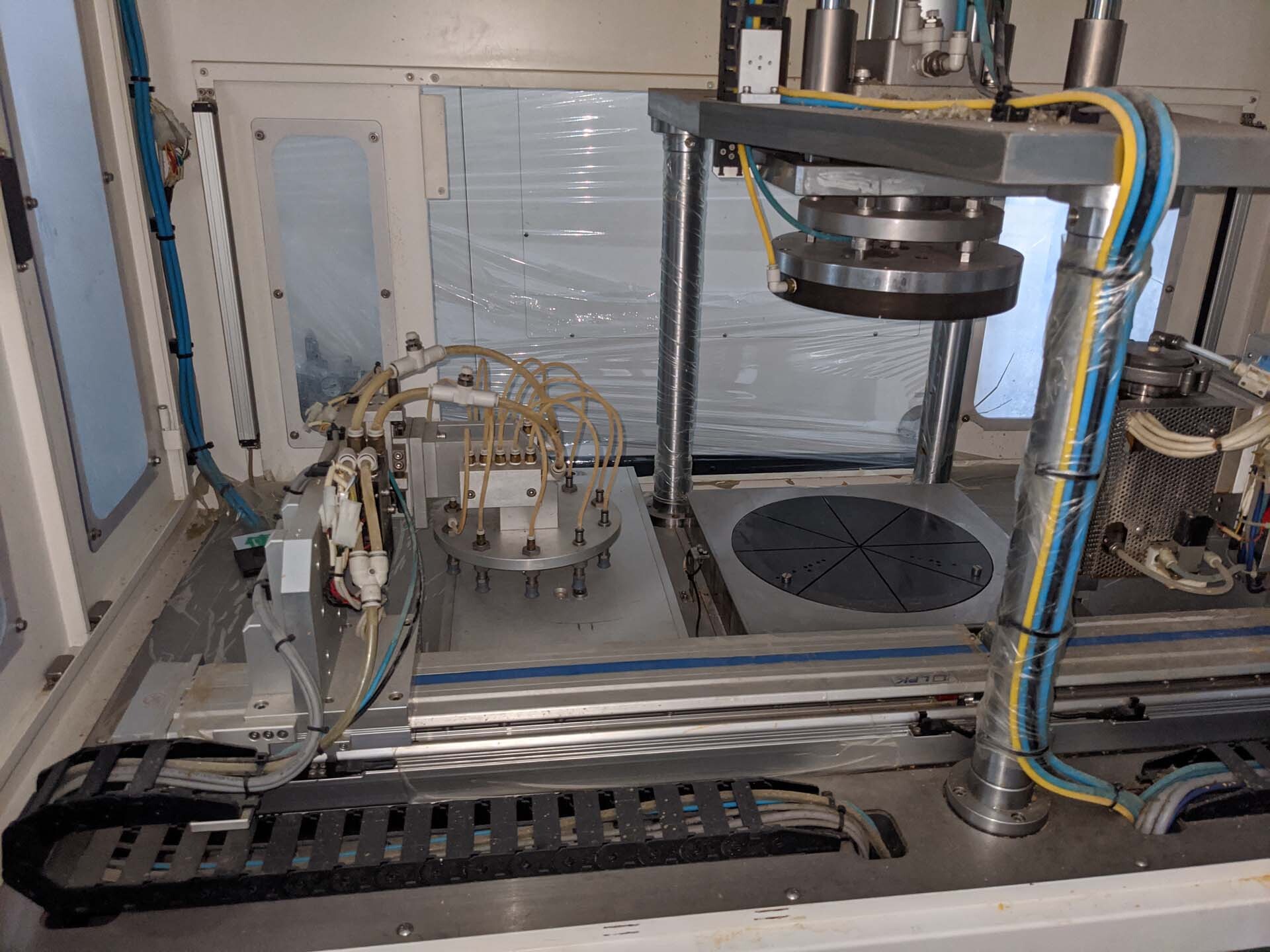

NTS NSB-1050V is a fully automated automated Wafer Grinding, Lapping and Polishing equipment. It is designed for a high-volume, high-precision production of optical components, MEMS, and other devices requiring a smooth, highly reflective surface. This system combines the efficiency of a multi- use turret unit with the accuracy of a single-use polishing tool. The versatility of the machine allows it to operate on a wide variety of materials, such as Si, GaAs, InP and quartz, as well as substrates of any thickness and size. NSB-1050V is designed with innovative features that provide superior performance in precision grinding, lapping, and polishing of components. The tool uses a pair of linear servo motors, combined with a precision rotary encoder, to provide highly accurate movement. This allows the turntable to move in both X and Y directions at a very high speed. This asset also offers fully adjustable settings for consistency and repeatability when processing different types of components. NTS NSB-1050V also features a wide range of options for controlling the grinding, lapping and polishing process. For example, it supports the integration of various control units that are responsible for controlling different parameters, including pressure, rotational speed and feed rate. The powerful software used by the model efficiently processes the settings and generates the optimal process parameters for a given application. NSB-1050V offers a highly efficient cleaning equipment for the polishing pad and turntable. This prevents the build-up of surface contaminants and ensures that the particles created during grinding and polishing operations are efficiently removed. NTS NSB-1050V also has an integrated safety system that offers maximum safety when grinding and polishing. Overall, NSB-1050V is a highly versatile and efficient wafer grinding, lapping and polishing unit. It provides efficient grinding and polishing of various types of substrates and substrates of any size and thickness. Its advanced control machine and integrated cleaning tool ensure reliable and consistent results. It is suitable for a range of demanding applications and is capable of producing high-tolerance, highly reflective surfaces.

There are no reviews yet