Used SPEEDFAM 16B-5P #9252228 for sale

URL successfully copied!

Tap to zoom

ID: 9252228

Vintage: 2002

Double sided polishing machines

Polishing plate: 1,125 mm (Dia)

Star wheel:

(5) Fixtures

Clamp: 426 mm (Dia)

Single beam

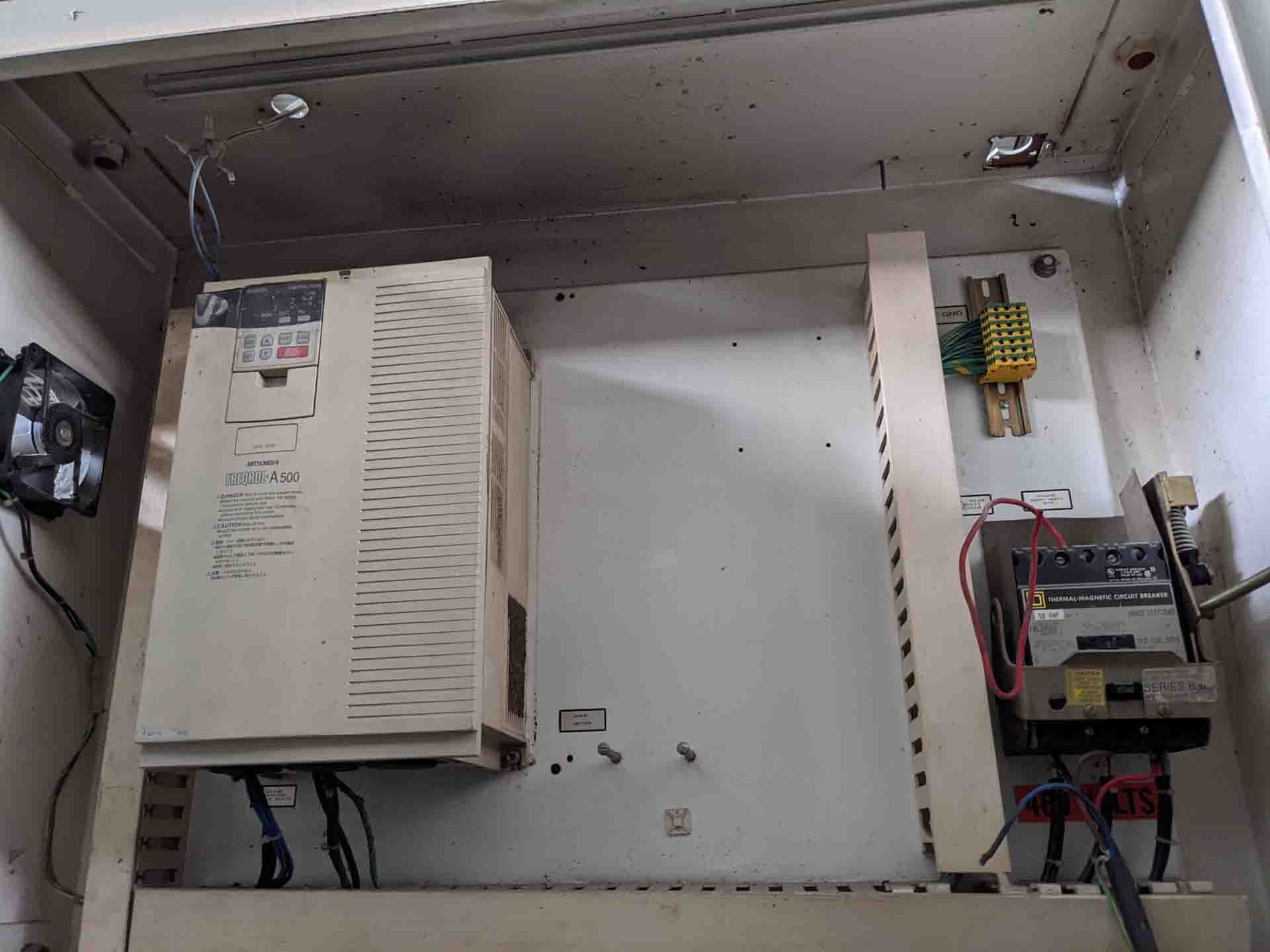

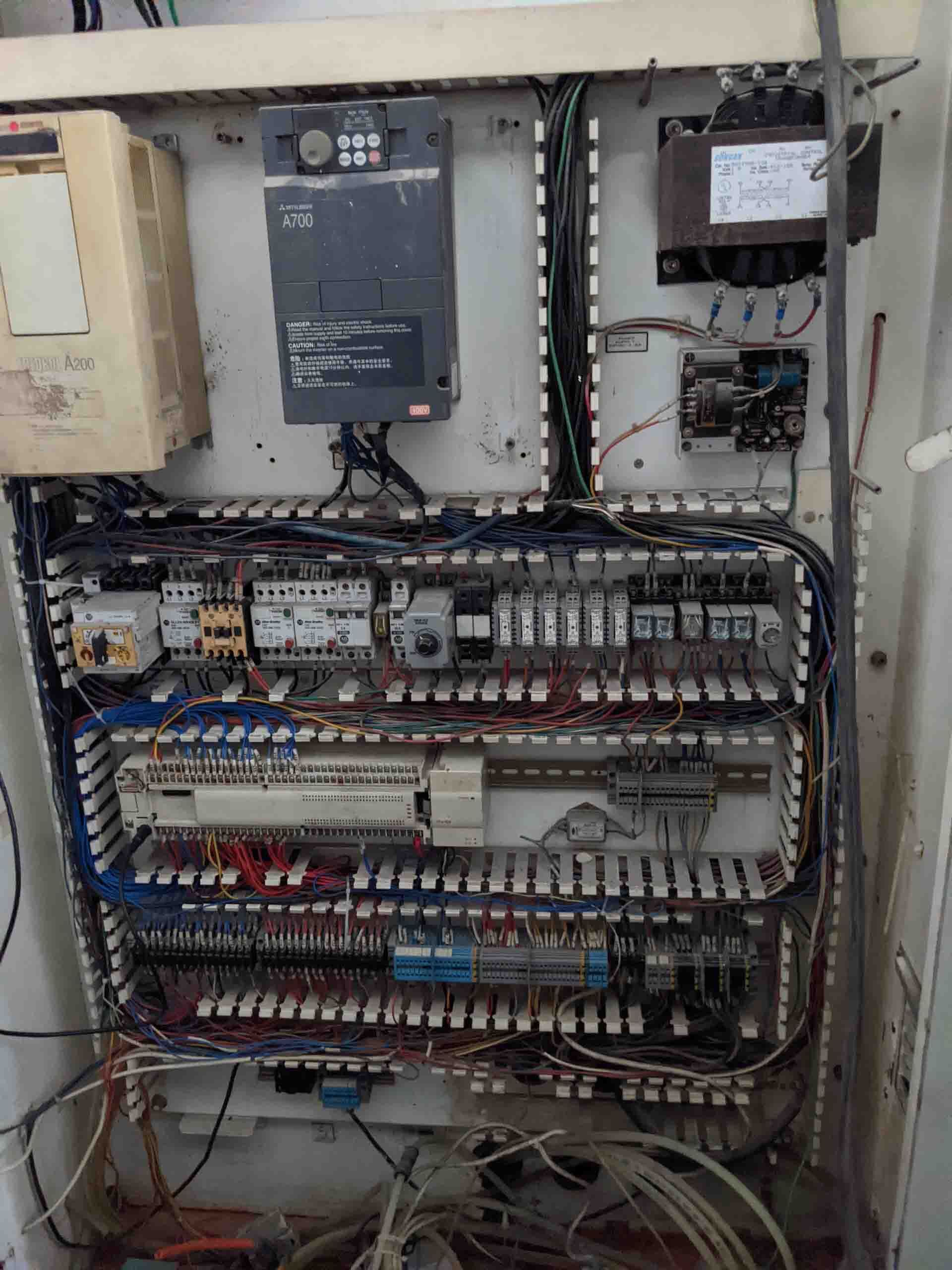

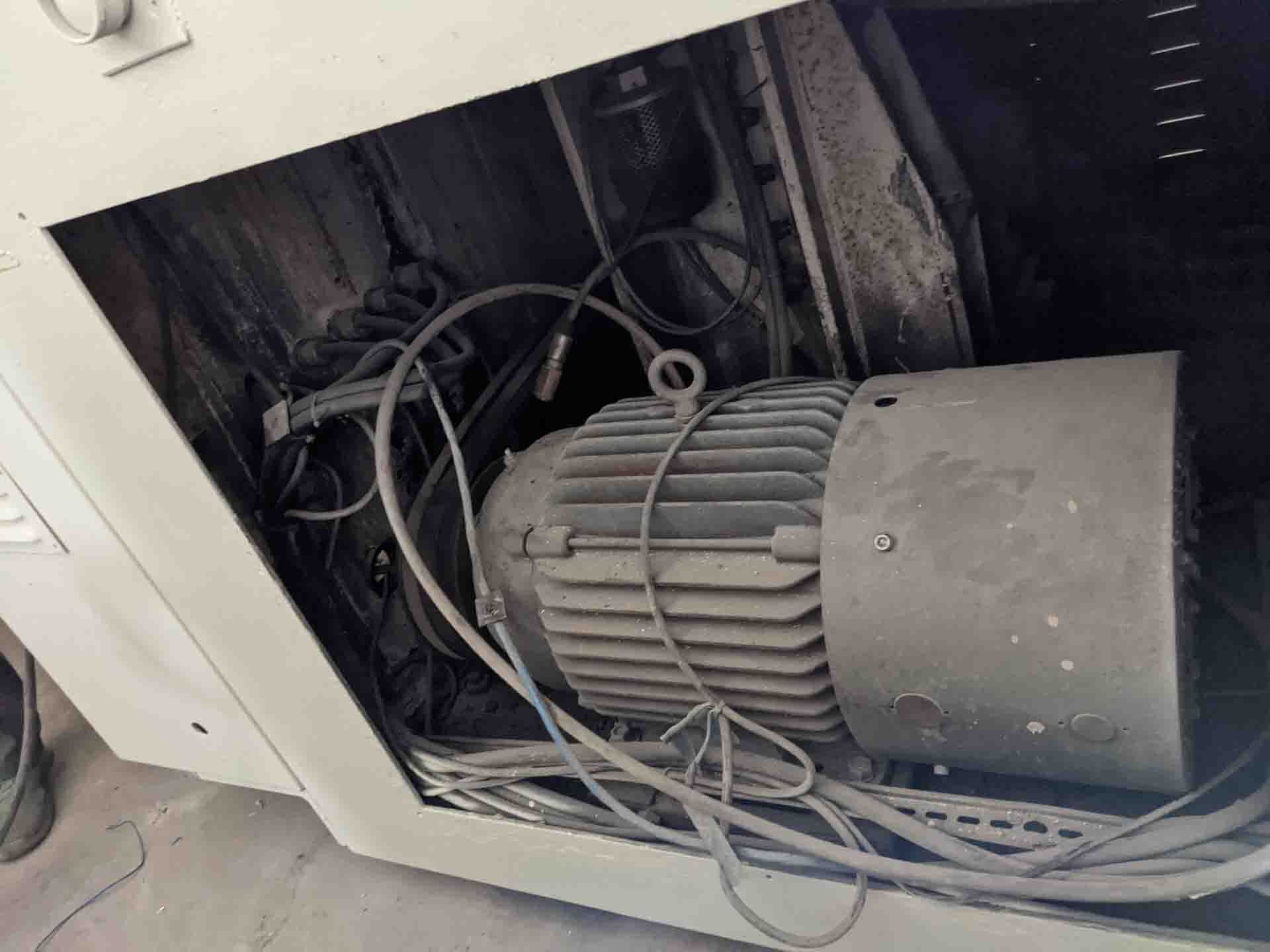

Motor

Press method: Air cylinder pressure

Pressure control: 2-Sections ((2) Stages)

Power supply: 220 V

2002 vintage.

SPEEDFAM 16B-5P Wafer Grinding, Lapping & Polishing Equipment is a precision grinding system for achieving the highest level of wafer production quality. It is designed to grind, lap, and polish thin wafers used in electronics and semiconductors. The unit consists of a robust, closed-loop precise control machine that maintains exact polishing pressure, feed rate, and particle size distribution. The tool's main components are a grinding table, lapping table, polishing table, and a wafer-handling asset. The grinding table features an abrasive slurry flow via a slurry pump, as well as a pressure distribution control model. Abrasive slurries can be applied to the grinding table to achieve the desired size reduction of the wafer. Additionally, the grinding table can utilize different types of grinding stones in order to obtain the desired surface finish. The lapping table features a wide range of lapping media, including abrasive powders and slurries which are used to adjust the wafer flatness. Additionally, it is equipped with an adjustable pressure equipment, enabling uniform lapping pressure, and dust collection systems for collecting lapping dust generated during the process. The polishing table provides an environment eliminating random scratches on the wafer surface. The Polishing table features a uniform, electrically controlled polishing head which ensures consistent flatness and surface finish. Also, the polishing head is driven by a motor and can be stopped immediately if the grinding pressure exceeds the preset limit. The wafer handling system features automatic wafer loading, unloading and transfer capabilities. The automatic loading and unloading unit eliminates the need for manual intervention in the grinding process. Additionally, it significantly improves the throughput of the machine by transferring the wafers quickly and efficiently between the grinding and polishing stages of the process. 16B-5P tool offers advanced process control and user- friendly software, allowing the user to program the grinding, lapping and polishing parameters. This provides the users with the ability to optimize the production process for volume efficiency. The asset is designed to minimize material waste and improve the wafer quality. Furthermore, the model is designed for maximum safety and flexibility, as well as providing a clean and dust-free work environment.

There are no reviews yet