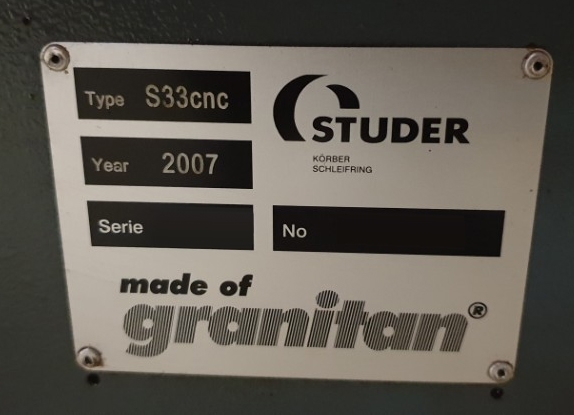

Used STUDER S33 #9265983 for sale

URL successfully copied!

Tap to zoom

ID: 9265983

Vintage: 2007

CNC Cylindrical grinding machine

Control: FANUC 21iTB

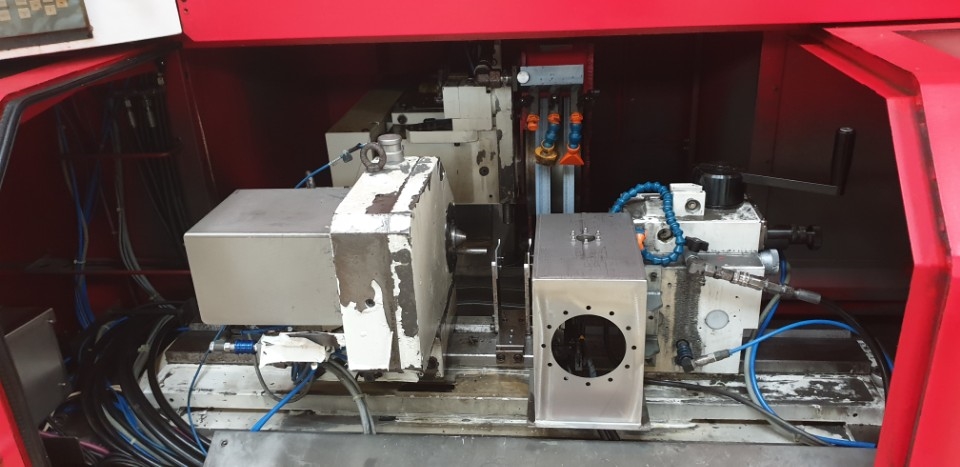

Distance between center: 650 mm

Center height: 175 mm

Distance between centers: 650 mm

Stroke (X,Z): 285 mm x 800 mm

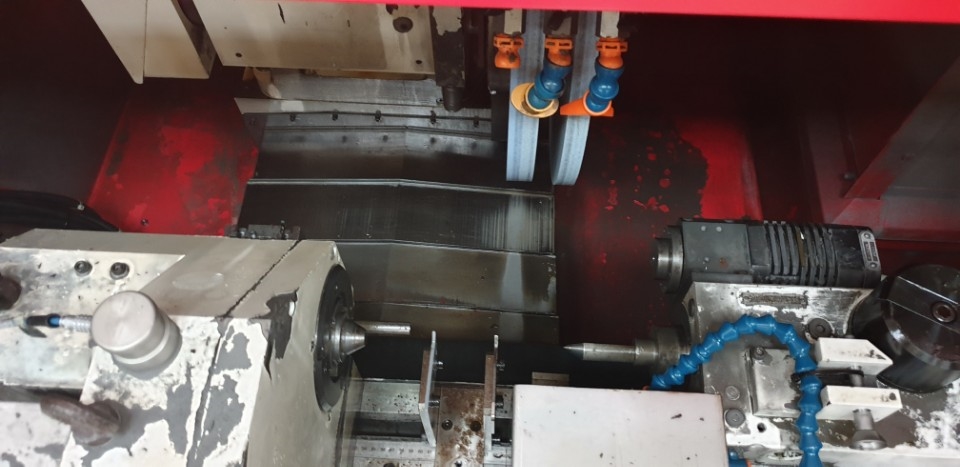

Grinding wheel head turning axis (B axis): Automatic turning type

Grinding wheel:

Maximum speed: 40000 rpm

Working diameter: 13 - 45 mm

Tailstock:

Taper: MT3

Stroke: 35 mm

Barrel diameter: 50 mm

2007 vintage.

STUDER S33 wafer grinding, lapping, and polishing equipment is an ideal machine for high-precision and high-throughput wafer-processing applications. Suitable for a wide range of wafer sizes and shapes, S33 is designed to process single and multi-level substrates with up to 400mm diameter. The system combines a wide range of technologies to guarantee exceptional levels of performance and flexibility. STUDER S33 utilizes a complete and advanced drive unit to enable various wafer speed ranges. This is achieved via an inverted pendulum, an AC linear motor, a high-performance servo motor spindle, a drive belt, and a double-stage gearbox. This combination ensures highly accurate and ultra-precise single- or multi-level wafer processing. The double stage gearbox also enables low-vibration and low-noise operation even during aggressive grinding and polishing cycles. S33 is equipped with a control-machine package that provides full automated control via a modern touchscreen control located in the machine. Users can simply select the desired parameters for wafer grinding and polishing, as well as inspect processes while the machine is running. Additionally, STUDER S33 features an integrated dry cassette containing diamond grinding and polishing heads to ensure accurate and repeatable processes for a wide range of wafer geometries. S33 also uses a vacuum tool to completely eliminate the risk of contamination resulting from airborne particles. This independent asset uses powerful filters to ensure all wafers are meticulously clean. In addition to this, STUDER S33's air management model ensures that all equipment and components are kept temperature stabilized using an independent atmosphere control equipment. S33 has a quality control software package to enable a closed-loop process. This allows users to access a range of functions such as programmable target grinding, measuring, and logging of finished wafers to a local or online database. Additionally, this enables users to specify set points for every cycle, while dry calibration and air pressure for each station ensure precise and consistent performance at all times. In conclusion, STUDER S33 wafer grinding, lapping, and polishing system is a modern and efficient unit for precision wafer processing. With robust construction, and a range of integrated features, S33 is ideal for a variety of applications such as those which require high-precision and repeatability.

There are no reviews yet