Used RENA WTS Distribution #9190348 for sale

URL successfully copied!

Tap to zoom

ID: 9190348

Loader

Control cabinet (WxDxH): 1600 mm x 500 mm x 2200 mm

MTBF: > 500h

MTBA: > 24h

ED-Uptime: > 95%

MTTR: < 4h.

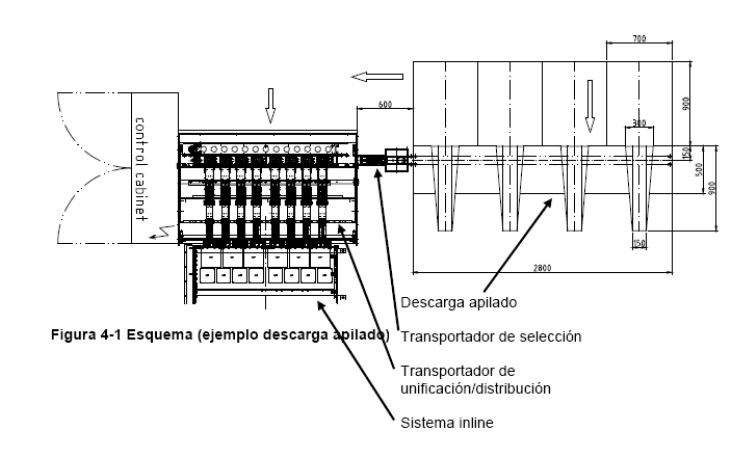

RENA WTS Distribution is a high-precision wafer handler designed to transfer thin and fragile wafers with high accuracy and repeatability. It offers a variety of features, including a multi-functional robot arm, standalone transport equipment, and wafer pre-aligner. The robot arm uses an advanced three-axis system to reach the load points in three-dimensional space. The standalone transport unit is specifically designed to ensure maximum safety and speed of wafer handling, without compromising on accuracy. The integrated wafer pre-aligner can independently check, adjust, and align each wafer before processing. WTS Distribution can handle wafers up to 300mm in diameter and is capable of transferring wafers with accuracy and repeatability to a maximum speed of 1200mm/s in high-volume production environments. The robot arm has an adjustable base clip that makes it easy to adjust the actuator pressure required to cleanly pick up and move the wafers. Its integrated vision machine is able to detect the wafer's position and detect defects in one step, increasing overall production efficiency. In addition to its handling capabilities, RENA WTS Distribution also offers advanced process control functions for sophisticated wafer handling. Its intuitive user interface makes it easy to programming, with various functions such as program memory, amount of recipes stored, multi-language support, recipe loading, user-level passwords, and more. The tool also features an ultra-precise motion controller, which uses a PID control algorithm to accurately follow the pre-programmed instructions. WTS Distribution is able to accommodate a variety of wafer materials, including silicon, ceramic, and sapphire. The asset is designed to operate in a variety of cleanroom environments, with a rotatable wafer cassettes and quick adjustability for different heights. It has monitoring functions such as motion alarm, total count detection, and air pressure detection, offering a safe and reliable handling process. Its comprehensive design helps to reduce the downtime, minimize operator errors, and maximize the accuracy of wafer handling.

There are no reviews yet