Used RENA WTS Distribution #9267707 for sale

URL successfully copied!

Tap to zoom

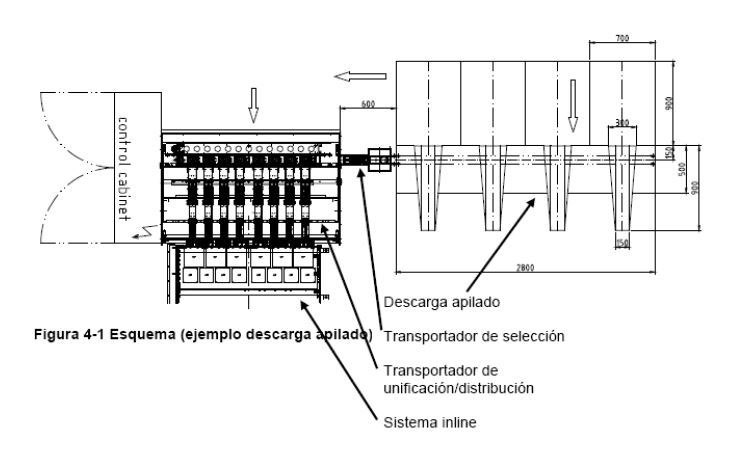

RENA WTS Distribution is a wafer handler designed for high-volume production in the semiconductor industry. This semi-automated equipment is composed of two primary components: a Wafer Tracking System (WTS) and a Wafer Distribution Unit (WDS). The WTS is responsible for tracking wafer movements and providing a real-time, visual display of wafer positions and statuses. The WDS is used to automate the actual movement of wafers between carriers, processing and metrology equipment, testing systems, load locks, and other periphery locations. The WTS and WDS are controlled by the intuitive, user-friendly RENA software. WTS Distribution also includes a separate robotized sorting machine for batch loading of wafers into their carriers or cassettes. This tool is designed to support up to 24 carriers containing 8-inch or 12-inch wafers. The architecture can be either strictly decentralized, distributed, or centralized, and can be combined with factory automation systems. RENA WTS Distribution is designed to provide improved throughput and utilization, enhanced wafer tracking accuracy, improved fault handling, decreased use of buffer space and improved safety, both through the use of advanced scanners and safety zones. WTS Distribution is capable of full production management through its software architecture. Through this architecture, it is capable of viewing asset errors, interfacing with equipment like thin-film metrology tools, automating material handling processes, establishing time management, and enabling remote maintenance. In addition, the software can update, keep track and synchronize metrology data between semiconductor and digital systems. The user can also program the model to perform various commands, such as opening and closing process chambers, in order to reduce the complexity of manual operations. This wafer handler is designed for maximum reliability and accuracy. To ensure the highest product quality, it uses advanced scanners, ranging lasers, and safety zones to keep wafers safe and clean. It also has integrated data logging and IQ/OQ modules that ensure safety, performance, and accuracy. Additionally, RENA WTS Distribution utilizes two levels of redundancy to ensure the accuracy and reliability of the equipment. WTS Distribution is designed for maximum flexibility and scalability, so it can be tailored to meet any production requirements. The architecture enables integration with other leading software solutions, such as factory automation systems, quality management systems, yield management software, and enterprise systems. Through its comprehensive functionality and flexibility, RENA WTS Distribution provides companies with increased efficiency, improved product quality, and enhanced wafer tracking accuracy.

There are no reviews yet