Used STAUBLI RX90 #9010342 for sale

URL successfully copied!

Tap to zoom

ID: 9010342

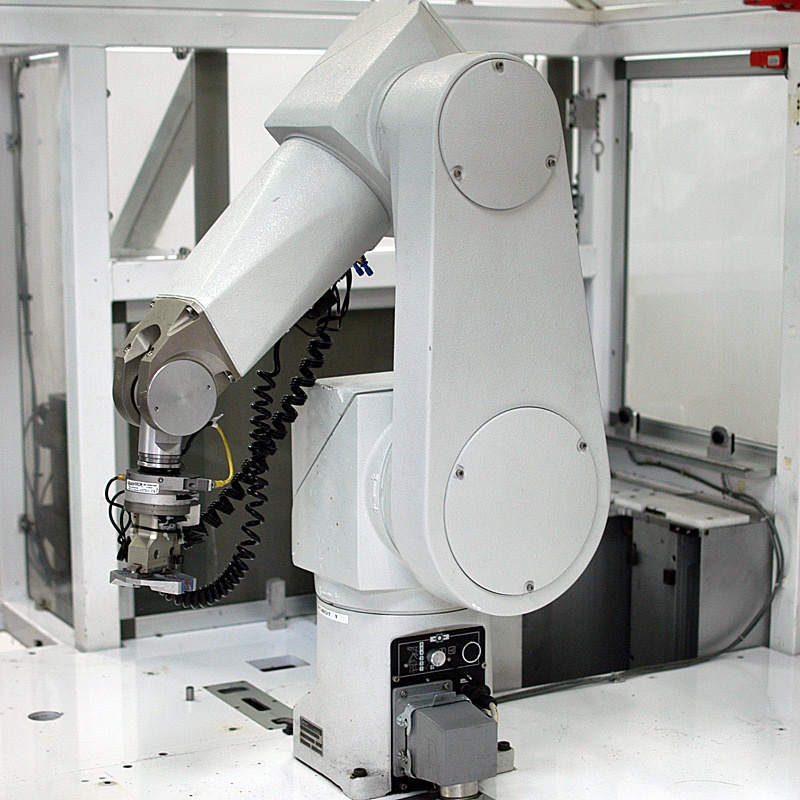

6-axis robot arm

Includes:

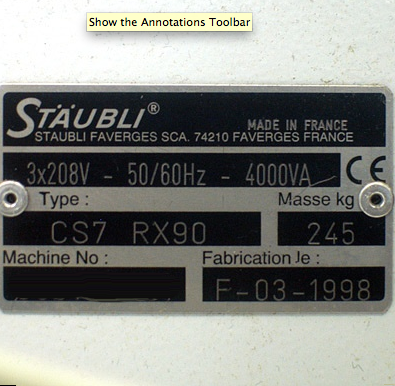

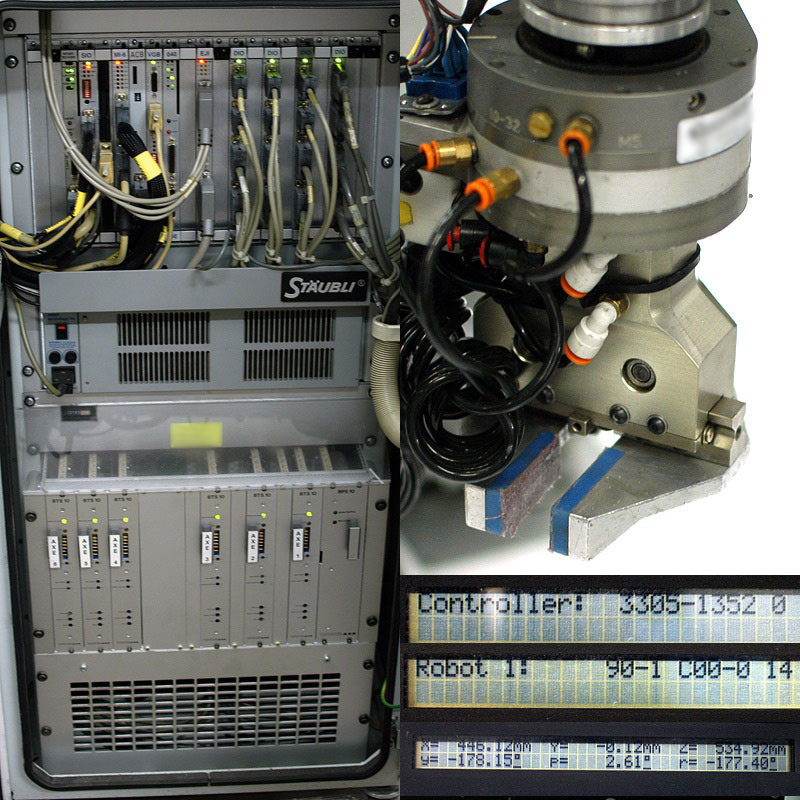

(1) Staubli CS7 RX90 control cabinet

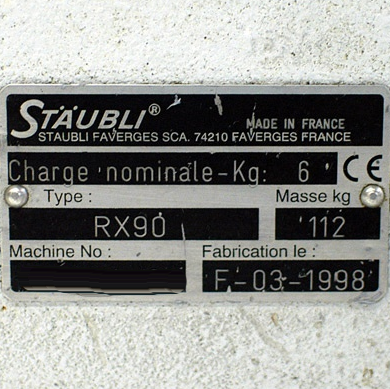

(1) Staubli RX90 robot arm

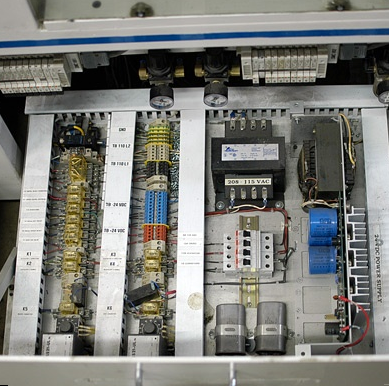

(1) Adept MV-19 controller

(1) MVME 162-520A control computer

(1) Baldor ASR servo drive cabinet with (6) BTS10 servo amplifiers

(1) Applied Robotics QuickSTOP QS-100NP-T3 quick change hand

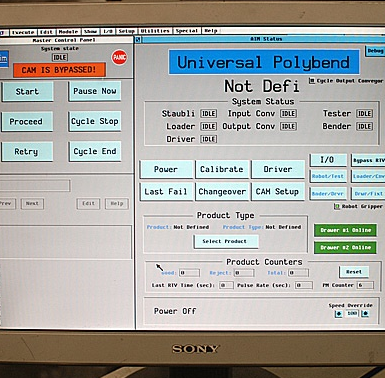

Software: Adept AIM System Version 3.1D1 with Motionware, Robot, ADX modules

Specifications:

With work cell (or without, your choice)

Nominal load capacity: 6kg

Maximum load (consult Staubli): 11kg

Reach: 985mm

Repeatability: 0.02mm

Mounting: floor or ceiling

Rated robot motion speed

Axis 1: 240º/s

Axis 2: 200º/s

Axis 3: 286º/s

Axis 4: 401º/s

Axis 5: 320º/s

Axis 6: 580º/s

Power: 208V 3phase 4000VA

Cabinet has outputs for (4) additional axes ((3) were used with Adept linear modules)

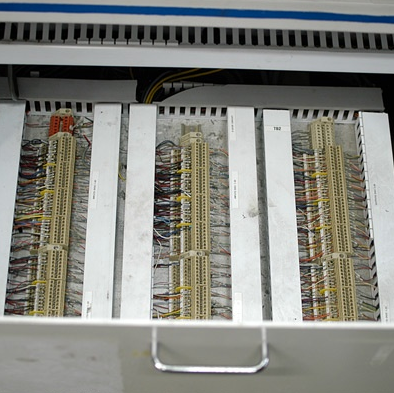

Table has (4) slide-out drawers, (2) loader/unloader machines in drawers

Table has penetrations for cables, threaded holes for fixtures

Controller hours: 70163

1998 vintage.

STAUBLI RX90 Wafer Handler is a robotic arm designed for high throughput, precision handling of semiconductor wafers. STAUBLI RX 90 has six axes of motion, allowing it to perform 3D movements with a maximum reach of 600 mm. It contains five joint motors, four for driving the robot's wrist and one for controlling its maximum speed. RX90 has a static capacity of up to 50 kg and can handle various sizes of semiconductor wafers ranging from 3" up to 8". As an added feature, RX 90 has a graphical user interface and programmable logic controls functions, allowing engineers to monitor process results, analyze data and create custom commands. STAUBLI RX90 is equipped with a low-impedance linear actuator, which allows for low-force, high-precision motion, ensuring that wafer placement is handled accurately and without damage. It is also equipped with a singularity control function, which prevents joint motors from sustaining a dangerous level of torque. Additionally, STAUBLI RX 90 contains an integrated vision equipment, which is composed of two cameras with vision guidance and marker recognition features. This system allows for an automatic wafer indexing process, pattern recognition, and wafer alignment. The vision unit also utilizes a fully automated vacuum suction machine, which allows for a secure tool grip and uniform wafer movement. RX90 runs on STAUBLI SCARA technology, meaning that it has both stable torque and high acceleration rates as well as unique programmed motion paths. This ensures wafer handling with precision and efficiency. Moreover, RX 90 is compatible with STAUBLI Smart Card tool, allowing for rapid and easy programming of custom robots without manual intervention. STAUBLI RX90 Wafer Handler is a reliable and efficient robot arm, designed for picking and placing semiconductor wafers. Its robust construction and streamlined design allow for precision-based placements with safty and accuracy. Its integrated vision asset and customizable software make it perfect for a variety of applications such as sorting and testing.

There are no reviews yet