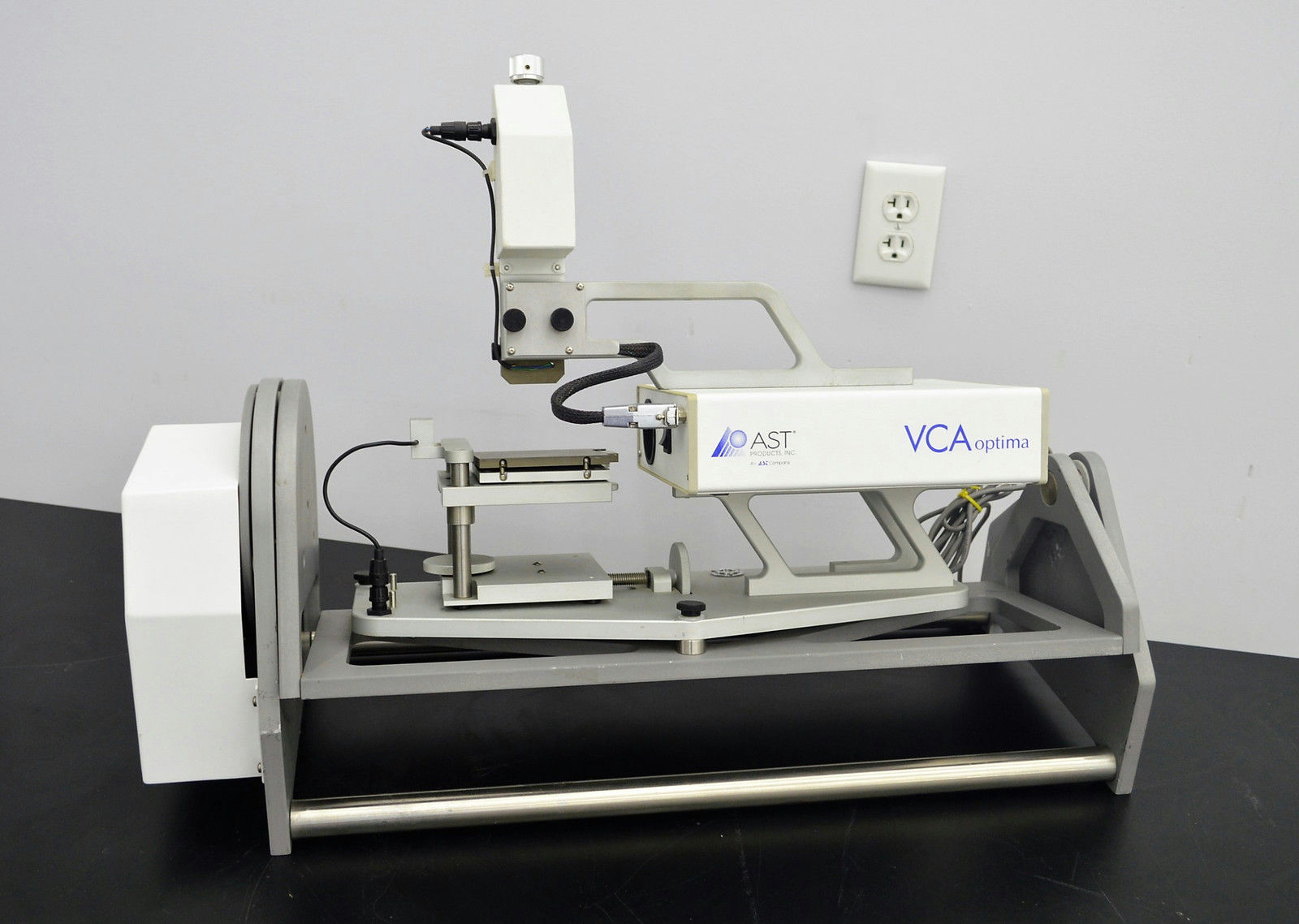

Used AST PRODUCTS VCA Optima #9171616 for sale

URL successfully copied!

Tap to zoom

ID: 9171616

Vintage: 2002

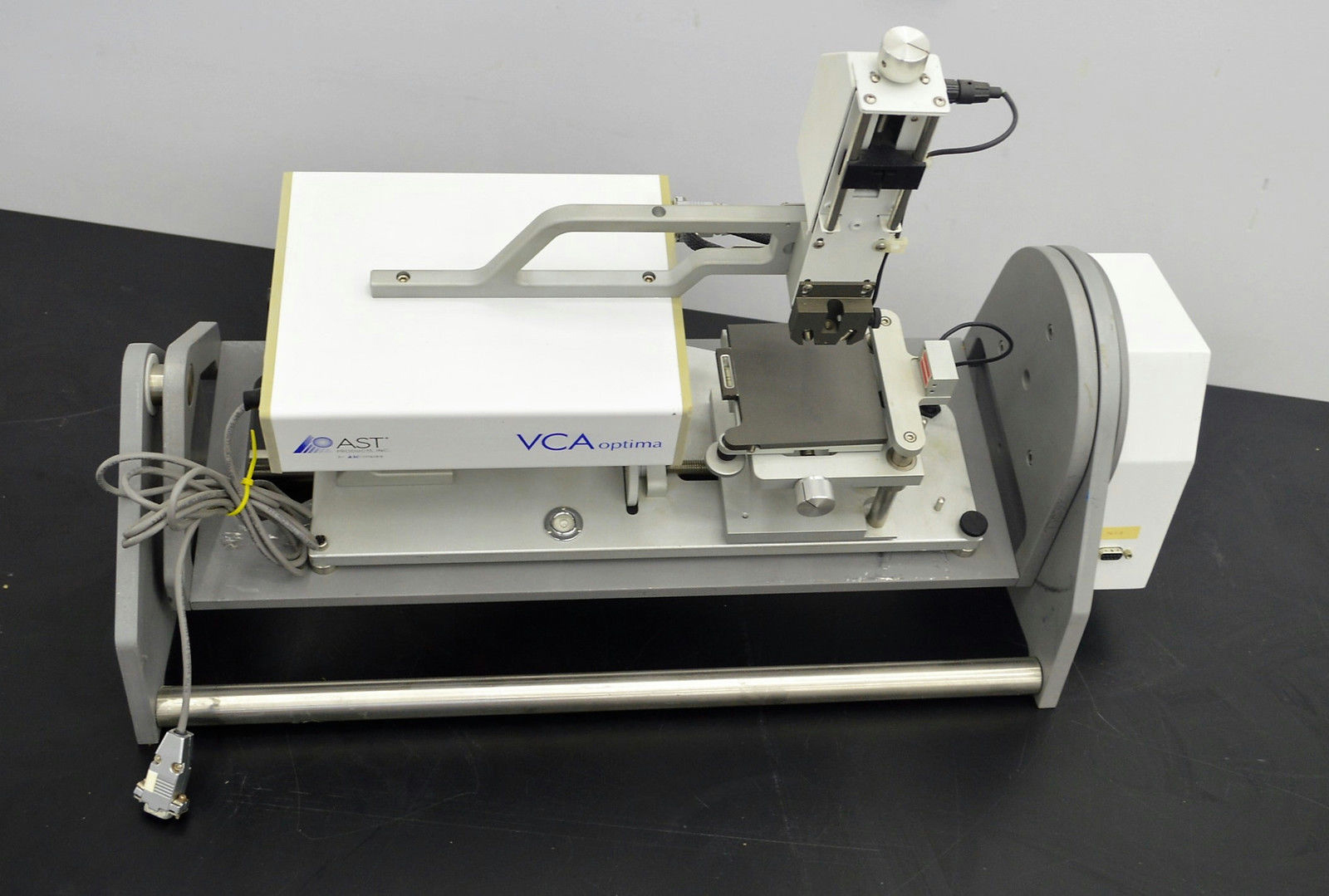

Contact angle measurement system

With tilt base droplet surface inspection

Precision camera

Advanced PC technology to capture static/dynamic images

Droplet tangent lines

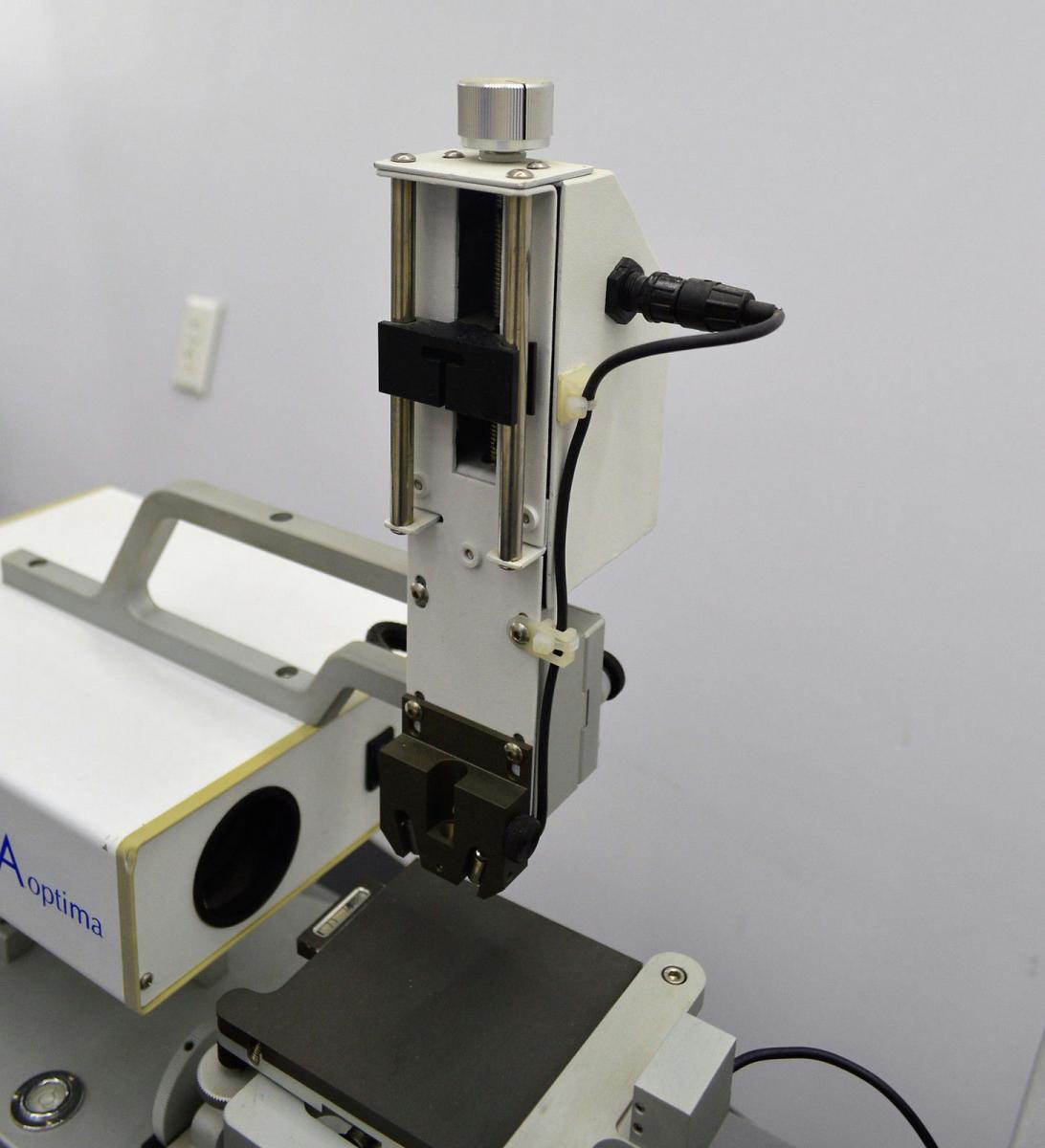

Manual / Automatic syringe provides easy dispensing of test liquid

Computerized operation eliminates human error in line drawing

Captures dynamic images for time sensitive analysis

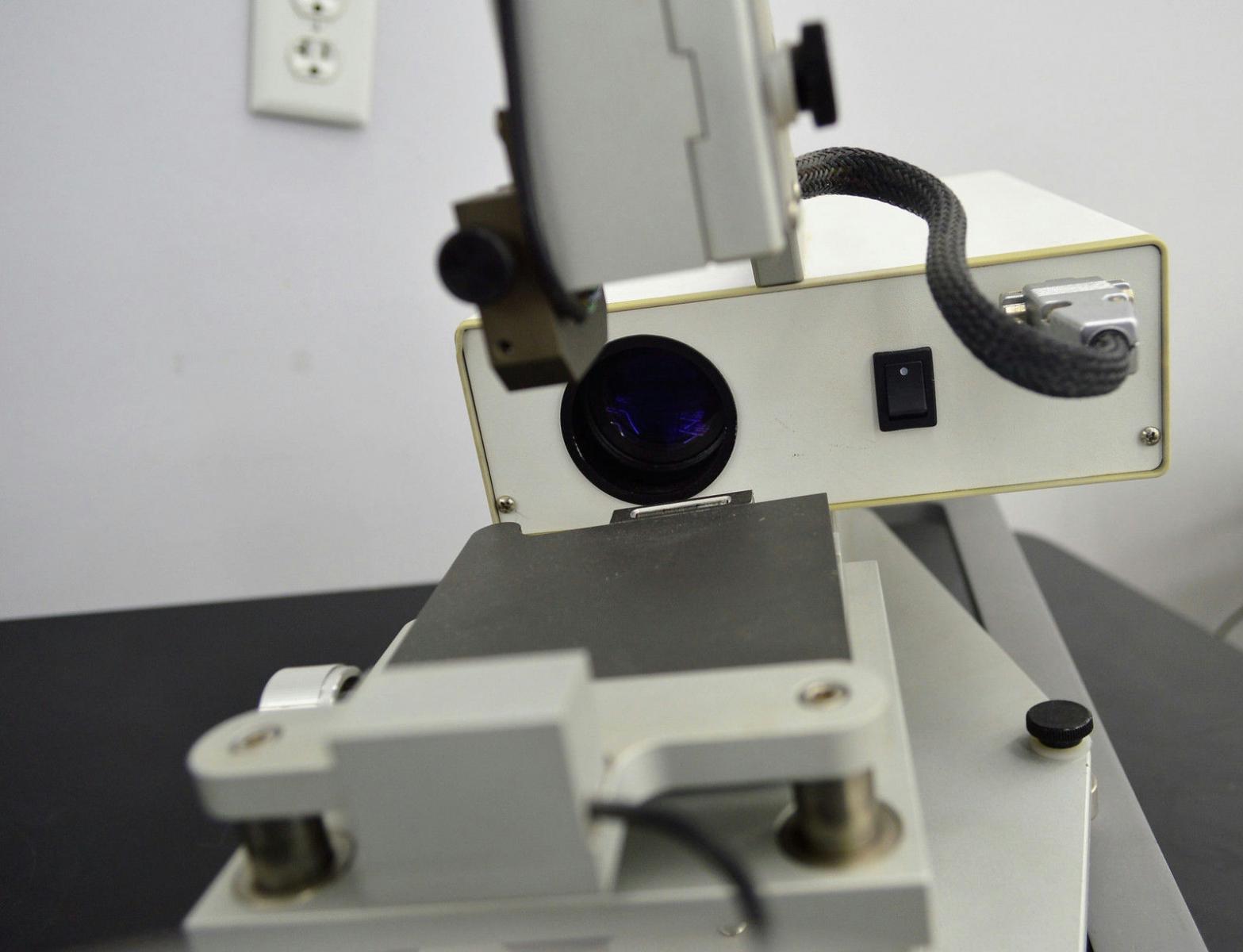

High-resolution video camera with powerful lens system for fine image focus

Solid state lighting for sharper / Brighter images

High-end PC standard with high-performance video board

Three-dimensional adjustable stage for accurate sample position

Standard motorized syringe: XE Model

Single control box: Easy setup

Small footprint requires less counter space

Measuring range: 0-180º

Repeatability: 1º

Accuracy: 0.5º

Magnification: 35:1 (high mag until 51:1)

Sample/specimen stage sizes: 3.5” x 3.5” max

Dosing: 150-500 droplets

Input voltage: 110 V, 50/60 Hz

Standard accessories:

(5) Needle tips (28 g)

(3) Syringes (100 ml)

Motorized syringe: (XE model only)

Not included:

Computer / Software

Power requirements: 120 V, 50/60 Hz

2002 vintage.

AST PRODUCTS VCA Optima is a wafer testing and metrology equipment that is used for performing fast and accurate optical testing and metrology of wafers. It has been manufactured using advanced optical and software technologies, which allow it to accurately measure wafer thickness and flatness. It also enables users to measure the critical dimensions of wafers quickly and accurately. VCA Optima system uses a sophisticated dual-gravity test head design, with two separate and interchangeable measuring fields. This design enables the unit to perform a range of different measurements including the thickness, flatness and surface roughness of wafers with high accuracy. This is possible because the test head is able to measure both the top and the bottom surfaces of the wafer simultaneously. The machine is also able to perform measurements on different wafer types, including conventional and advanced wafers. AST PRODUCTS VCA Optima tool uses advanced software algorithms to process the data that is obtained during the measurement process. This allows the asset to accurately calculate the critical dimensions of the wafer, including the total thickness, flatness, and surface roughness. The model also uses software mechanisms to ensure that only good wafers are accepted. In addition to measuring wafer thickness, flatness and surface roughness, VCA Optima equipment also includes a wafer characterization application. This software module provides users with detailed information about the performance characteristics of their wafers, including the topography, defects, average grain size and crystallinity. The system provides users with detailed statistics that can be used to analyze the performance of their wafers and to make appropriate improvement decisions. AST PRODUCTS VCA Optima unit is also designed with a range of safety features. This includes the use of safety-tested materials and components for its wafer handling machine. In addition, the tool also includes a wide range of security mechanisms to help protect against unauthorized access to the data stored in the asset. VCA Optima model has a small form factor and can be easily integrated with existing production processes. This makes it an ideal solution for measuring the critical dimensions of wafers accurately and quickly. The equipment is also reliable and easy to use, so it can be used by both experienced professionals and novice users with ease.

There are no reviews yet