Used VEECO / DIGITAL INSTRUMENTS Dimension VX 340 #9283468 for sale

URL successfully copied!

Tap to zoom

ID: 9283468

Atomic force profiler, 12"

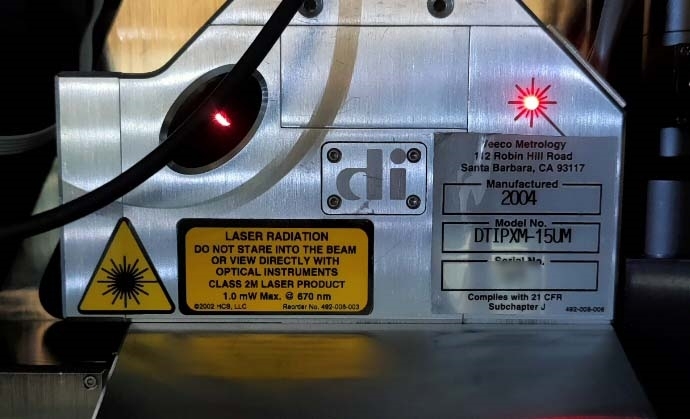

Head: 15 µm AFM

Chuck and pre-align type: Low contact

BROOKS Dual port ISO

Nominal scan range: XY 65 x 65 um, Z 15 um.

VEECO / DIGITAL INSTRUMENTS Dimension VX 340 Wafer Testing and Metrology Equipment is an advanced single-wafer inspection and metrology platform used in the semiconductor industry. This system utilizes the latest advancements in technology to ensure the highest levels of accuracy and precision in measuring, inspecting, and characterizing wafer surfaces. VEECO Dimension VX 340 unit uses a combination of scanning and optical microscopy to provide magnified views of the wafer from a wide array of perspectives. This data can then be used to accurately measure the physical dimensions and geometry of the device, allowing the user to confirm critical specifications that define the performance of the final product. DIGITAL INSTRUMENTS Dimension VX 340 utilizes advanced imaging, optical, and spectroscopic metrology techniques to characterize the physical and chemical properties of wafer surface processes. It features two complimentary optical and imaging systems, providing a flexible and integrated platform for analyzing a variety of wafer surfaces. The machine also has a high throughput CCD imaging region which enables surface and film characterization of larger areas of a wafer. Dimension VX 340 is capable of characterizing quantitative values associated with wafer surface processes using a wide variety of techniques, including surface profilometry, ellipsometry, reflectance spectroscopy, IR spectroscopy, Raman spectroscopy, and atomic force microscopy (AFM). This data can then be used to assess the quality of products, examine the impact of processing conditions, model surfaces for design and optimization, and more. The tool can also perform post processing on the wafer such as extraction of feature data, image analysis, and process characterization. The asset includes integrated software which allows for easy data analysis and review of the results. This eliminates the need for manual analysis of data, and provides a more efficient and accurate way to manage critical wafer metrology processes. The model is designed to provide accurate and reliable results for multiple metrology applications in a wide range of industries. Its robust design and versatile applications make it an ideal choice for evaluating and processing a variety of wafer surfaces in a variety of applications.

There are no reviews yet