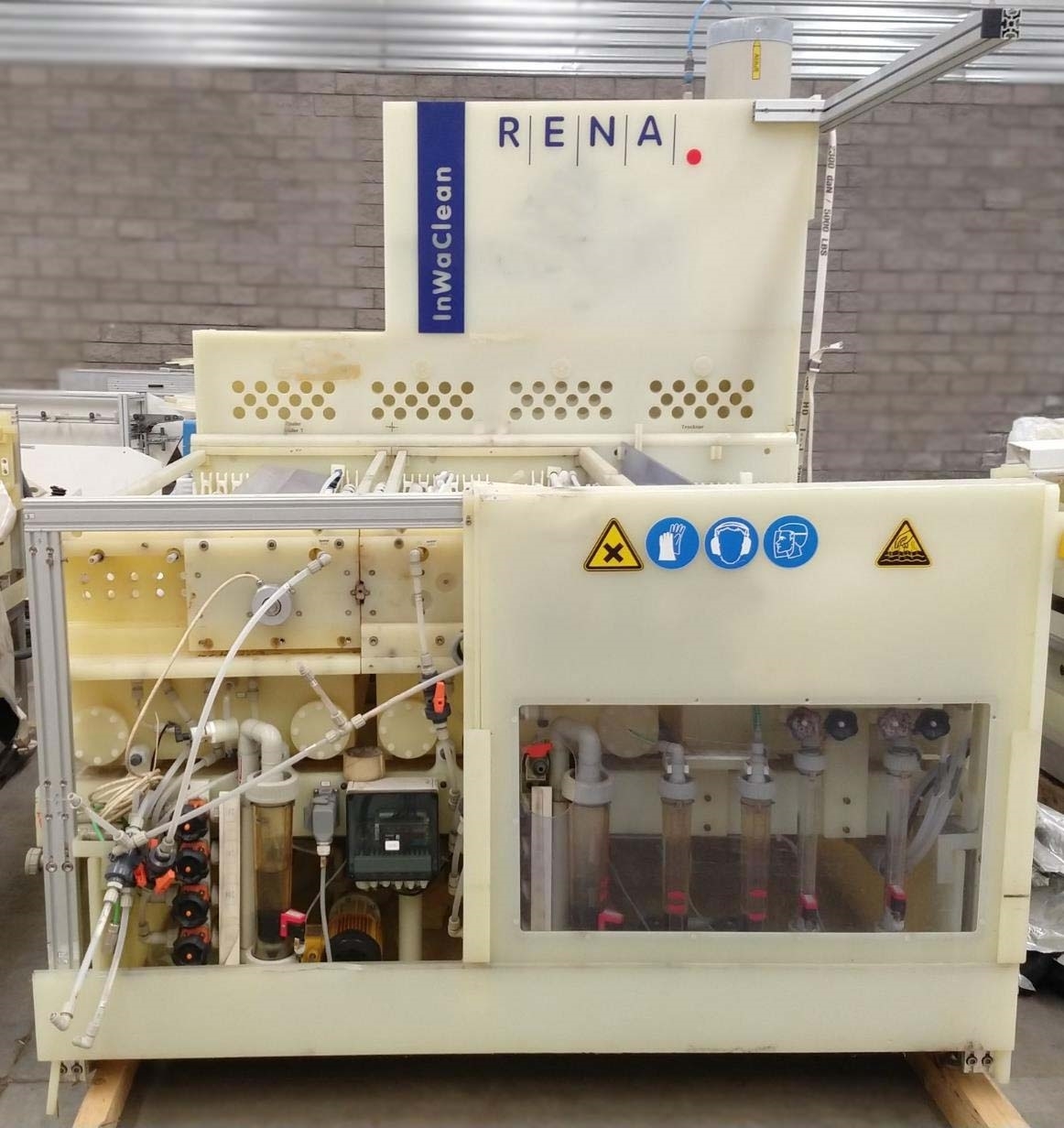

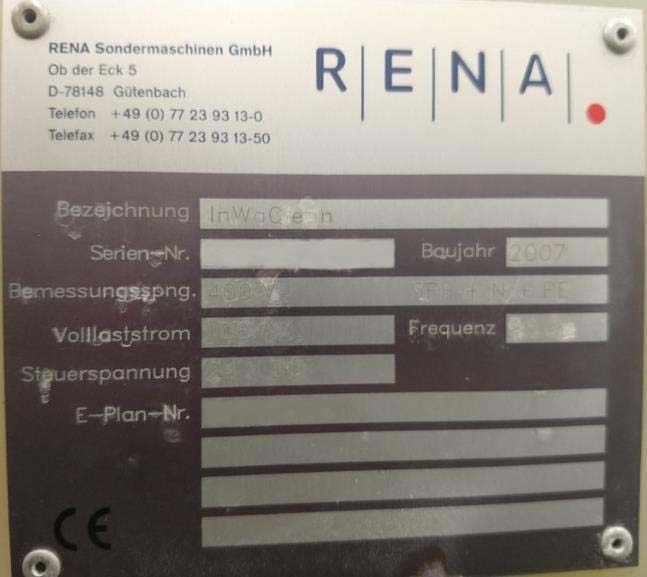

Used RENA InWaClean #9280717 for sale

URL successfully copied!

Tap to zoom

ID: 9280717

Vintage: 2006

Wet bench final cleaning system

Power: 400 V, 3 Ph+N+PE, 120 A, 50 Hz

CE Marked

2006 vintage.

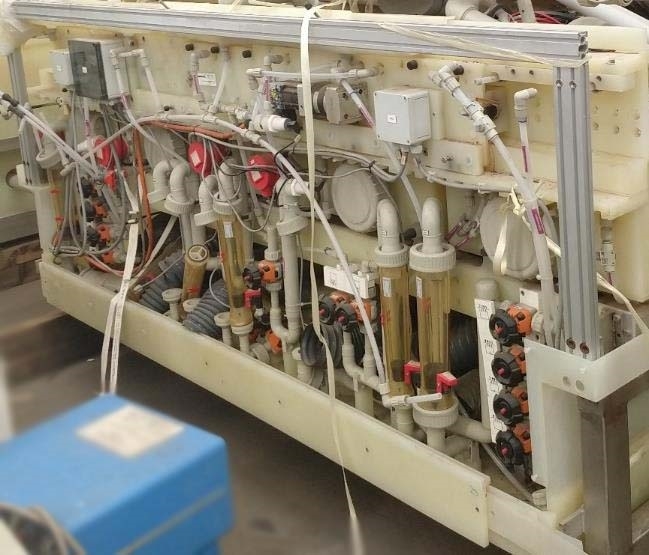

RENA InWaClean is a high-performance wet bench station that is designed for low-volume production of PCB assemblies. It features a superior cleaning process for removing solderpaste, flux residue, and other debris from the printed circuit boards (PCBs). The station utilizes precision air jets to gently yet powerfully remove contaminants from the board's surface. Its built-in liquid filtration system also helps keep the air clean and free of dust and particulates. InWaClean is made up of two parts: a cleaning head and a control unit. The cleaning head is designed to handle PCBs of up to 50mL in area. It is equipped with a high-pressure air jet, which is designed to apply a precise and consistent cleaning intensity to the board's surface. The control unit provides a graphical user interface (GUI) for controlling the various parameters of the cleaning head. Through this GUI, the user can control the angle, flow intensity, and duration of the cleaning process. In addition to its air jet cleaning process, RENA InWaClean uses a liquid filtration system to clean off the remaining contaminants. The liquid is applied to the surface of the board and then forced through a series of finely-meshed filters by a powerful pump. This process helps to remove even the finest residue particles that may be left behind after the air jet cleaning process. InWaClean is also designed for safety. An emergency-stop button is located on the control unit so that users can stop the cleaning cycle at any time. It is also designed for productivity, with a replaceable filter that can be replaced in a few seconds and minimal downtime. The station also features built-in diagnostics tools, which help to ensure accurate and optimal performance. Overall, RENA InWaClean provides a reliable and cost effective method for removing solderpaste, flux residue, and other debris from printed circuit boards. Its easy-to-use graphical user interface and built-in safety features make it ideal for low-volume production operations. It is also equipped with a powerful liquid filtration system for removing even the finest particles, making it an ideal choice for electronic manufacturing.

There are no reviews yet