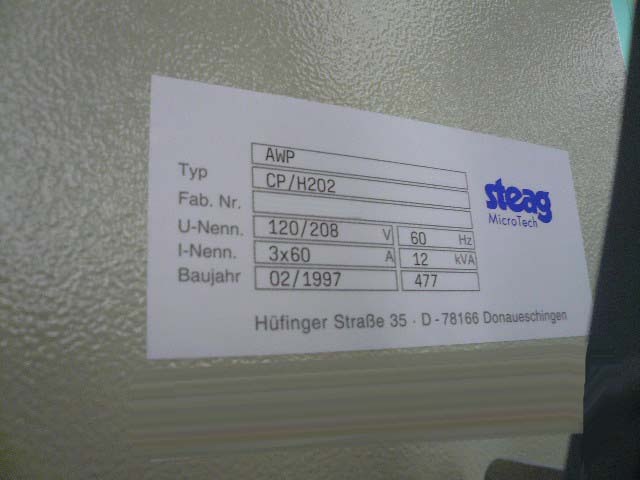

Used STEAG / MATTSON / AST AWP #9091162 for sale

URL successfully copied!

Tap to zoom

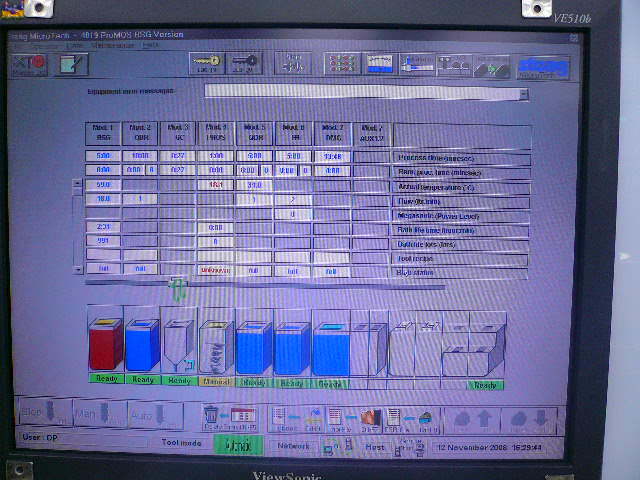

STEAG / MATTSON / AST AWP wet station is a reliable automated wet process line used in the production of industrial parts. This wet station offers a full suite of process options from etching to cleaning and can be used to improve both the appearance and physical properties of metal surfaces. AST AWP wet station provides several different process options including, etch-followed-by flux, spray rinsing, immersion cleaning, spray etching, and electrolytic etching. It has the ability to accommodate two different chemistries for each process as well as multiple rinsing steps. It also offers rinse water and chemical treatments including filtration, resins and ion exchange to provide the highest level of cleaning and etching. A high degree of process repeatability and control is ensured through STEAG AWP's remote access software package, which allows for process monitoring, data analysis, and troubleshooting. This software makes it easy to maintain the process and provides predictive alarms to help prevent costly downtime. In addition, AWP wet station's automated conveyor system is capable of transporting large parts at a rate of up to 10 meters per minute. It is also equipped with a special air-coupled tooling system that allows for the precision placement of parts into the plating cell, making it easy to achieve consistent part quality and batch times. An advanced data logging system provides a reliable record of the process results. It includes detailed statistical reports on the number of parts processed, temperature profiles, plating and etching layer thickness, plating and etching time, and process efficiency, making it easy to gain insight into the process and make improvements where necessary. In short, MATTSON AWP wet station is a highly efficient, reliable, and easy to use automated process line that can provide outstanding metal surfaces for industrial parts in a cost-effective manner. Its comprehensive process options, predictive alarms, easy to access remote software, and advanced data logging capabilities make it a great choice for any industry that requires high quality metal surfaces.

There are no reviews yet