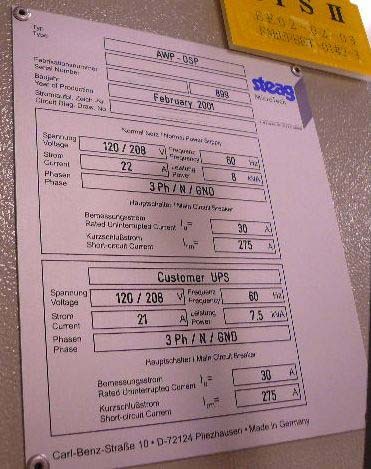

Used STEAG / MATTSON / AST AWP #9091165 for sale

URL successfully copied!

Tap to zoom

AST (SMAST) Automated Wet Process (STEAG / MATTSON / AST AWP) Station is an advanced, high-capacity wet-processing station designed for automated operation in semiconductor packaging and wafer assembly processes. The SMAST AST AWP Station is a complete, modular wet-processing platform engineered to reduce human intervention while consistently delivering process cycle times at optimal yields. The SMAST STEAG AWP Station includes three core functions that together provide an automated reaction environment inside the station: wafer and part handling, chemical processing, and post-process operation. The chemical processing platform is centrally located and modular, allowing for the customization of the processing cycle to specific customer needs. This flexible design eliminates unnecessary modules, reducing overall footprint and costs. The SMAST AWP Station also features automated wafer handling and automated storage and retrieval systems. The automated handling equipment utilizes robotic arms to transport wafers and parts between different process stages while providing complete physical isolation from contaminants. The storage and retrieval system keeps the wafer and part inventory at an optimal level and is designed to automatically fill the processing chambers with the necessary chemicals and solvents. The station also includes four main process tanks: a rinse tank, a pickling tank, a drying tank, and a seal tank. Inside the tanks, an advanced, multi-nozzlehead unit propriety from STEAG Technology is employed to provide the highest uniformity possible during the entire chemical process. The station has an integrated process controller connected to a personal computer for complete process customization and recipe documentation. The SMAST MATTSON AWP Station allows for a wide range of process chemistry and capability as well as allowing for both certified and non-certified chemicals. The user-friendly software platform is designed to monitor the progress of the processes and to identify any potential chemical or temperature discrepancies, allowing for process corrections and improvements in real-time. The SMAST STEAG / MATTSON / AST AWP Station is equipped with four cleaning systems: a liquid cleaner machine, a dry nitrogen cascade cleaning tool, a dry oxygen cascade cleaning asset, and an ultrasonic cleaning cycle. This wide range of cleaning solutions ensures the highest baseline quality of the product, while meeting all safety, environmental, and industrial specifications. Finally, the SMAST AST AWP Station features advanced environmental safeguards such as sophisticated ventilation, fume hoods, safety doors with ESD, and automated isolation. These safeguards are designed to maximize operational efficiency while protecting personnel and the environment in which the station is utilized.

There are no reviews yet