Used PHOENIX PCBA Analyser #9216535 for sale

URL successfully copied!

Tap to zoom

ID: 9216535

Vintage: 2000

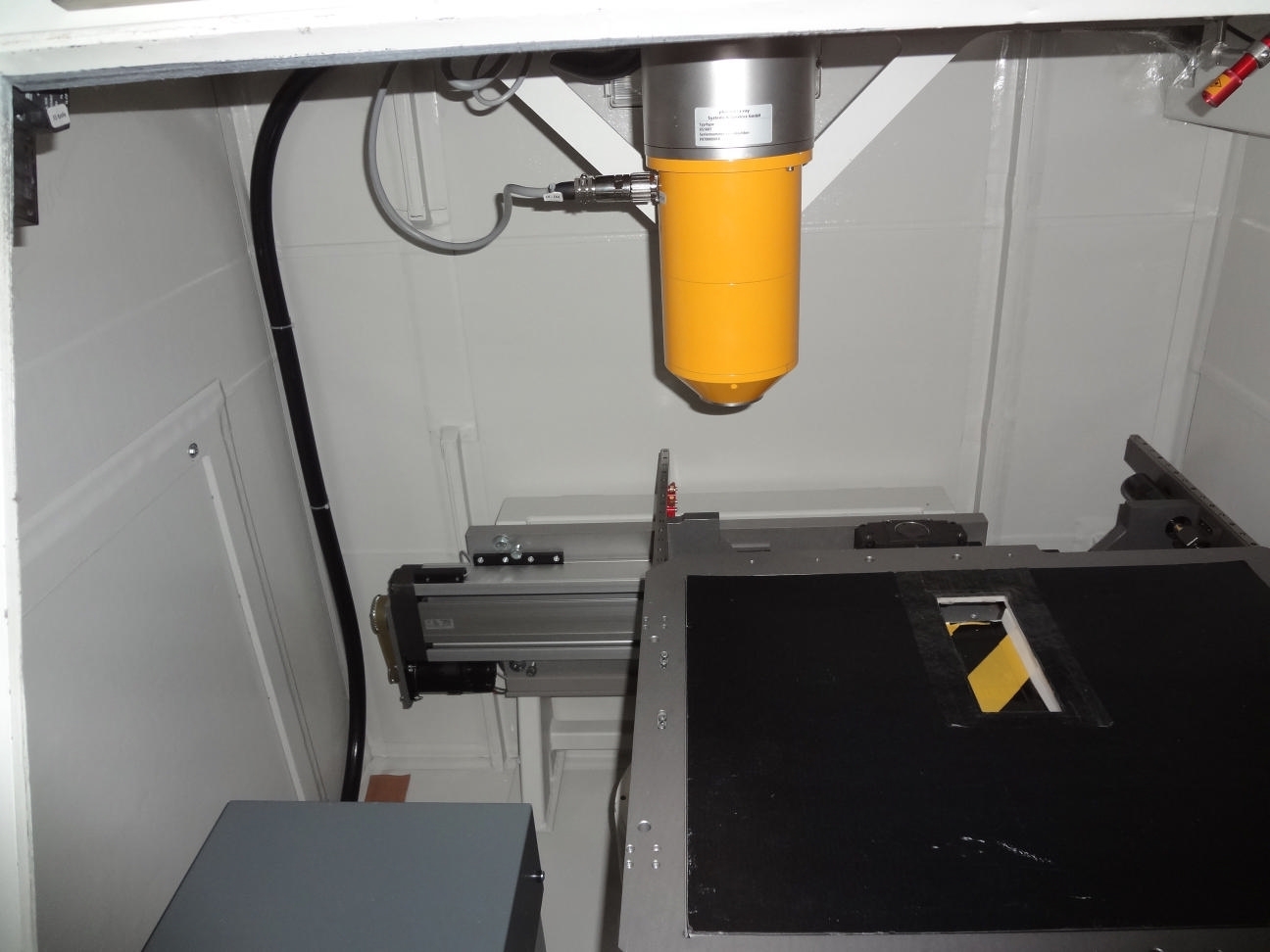

X-Ray inspection system

Ultra high resolution micro focus X-ray system with open tube

Inspection of IC packages

Capabilities:

Detail detectability: 1μm

Long life-time transmission tube

Simple and quick filament change

Various tube voltages

Geometric magnification: >1400x

Total magnification: >2500x

Multiple axis manipulation with APC

Windows NT based X-ray controller and image processing

Integrated noise suppression system

High resolution real-time image chain

Ergonomic design

Process / Production control and failure analysis of electronic components:

Die attach voiding

Inner lead and outer lead bond integrity

Wire sweep

Flip-chip to substrate bond integrity

Encapsulation faults

2000 vintage.

PHOENIX PCBA Analyser is an advanced equipment for x-ray inspection of printed circuit boards. It is designed to detect and evaluate faults such as shorts, opens and component misalignment quickly and accurately. The equipment employs specialized x-ray beams to penetrate PBC boards and reveal all discreet components, solder joints, and connections. The images of the board can be viewed in 3D with distortion correction and magnification up to 400X. This allows the user to effectively detect and report any physical defects. PCBA Analyser can also be used for component placement verification and BGA solder joint inspection. PHOENIX PCBA Analyser consists of the X-Ray Inspection System, Variable Angle X-Ray Source, and Monitoring Unit. The X-Ray Inspection machine is responsible for the tracking and speed control of the scans. The Variable Angle X-Ray Source is responsible for accurately directing the x-ray beams over the board, allowing for more accurate physical measurements. The Monitoring Tool is responsible for data acquisition and analysis from the scan, allowing for reports to be generated quickly. PCBA Analyser can detect various process-related defects and assembly-related defects. The process-related defects include excess solder voids, insufficient solder joints, and misalignment of components. The assembly-related defects include bad parts, missing parts, incorrect orientation of components, shorts, and opens. The asset also provides effective fault localization through its advanced 3D image processing techniques. The model is able to evaluate condition of components using subsequent scans and overlay the images in real time. This allows engineers to identify any changes on the board before the assembly process is complete. Additionally, the device has an automatic defect recognition feature that makes it easier to identify defects. The equipment can also be used for layer-by-layer inspection of PCBs. PHOENIX PCBA Analyser is a powerful and efficient tool for assessing PCBs. It is one of the best x-ray systems in the industry and provides high accuracy and reliable results. With its easy operation and excellent fault detection capabilities, it can help to increase the quality and reliability of PCBs.

There are no reviews yet