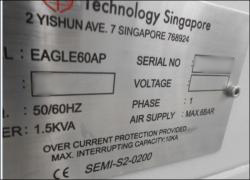

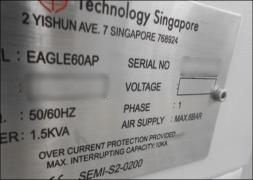

Used ASM Eagle 60AP #9191851 for sale

URL successfully copied!

Tap to zoom

ASM Eagle 60AP is an automated vacuum solder bonder equipment, designed for high-performance production of surface mount electronics assemblies. The bonder is capable of soldering components with lead-free alloys, SnBi and SnPb, and is equipped with a automated X/Y stage for accurate component placement. ASM EAGLE 60 AP is the latest addition to ASM family of solder bonders, a line of highly customizable and energy-efficient bonding systems. Eagle 60AP is built with a modular approach designed to deliver significant throughput and cost savings that are not found in conventional bonders. The system consists of a heated platform and a Z-axis guide rail for precise component placement, combined with advanced optical and image processing capabilities for detecting component position and orientation. EAGLE 60 AP can solder up to 0402 chip and 0625 fine-pitch components with Sn/Bi and Sn/Pb alloys, and achieves reflow temperatures of up to 260°C in less than 10 seconds. ASM Eagle 60AP's ergonomic design features an adjustable worktable, easy-to-use operators and intuitive programming interface. The bonder is powered by an advanced PLC (programmable logic controller) unit, which ensures consistent performance and accurate component placement. The bonder also includes a built-in vacuum flange, vacuum machine, alignment optics, vacuum hold-down tool, c-axis head, drive motors, and a conveyor asset integrated for smooth component flow. ASM EAGLE 60 AP has been designed for maximum flexibility. It can be programmed to handle up to three production runs simultaneously with different process parameters. The bonder also features a heater monitoring model with four temperature zones and 128 set points, and can be used with a variety of different materials, such as ceramic, polymer, and hybrid substrates. Eagle 60AP is the perfect choice for automated and streamlined production of small to medium size electronics components. Its precision soldering and accurate component placement make it ideal for high-volume production of delicate circuit board assemblies. The bonder's versatility and automation capabilities make it the perfect solution for streamlining production and reducing production times.

There are no reviews yet