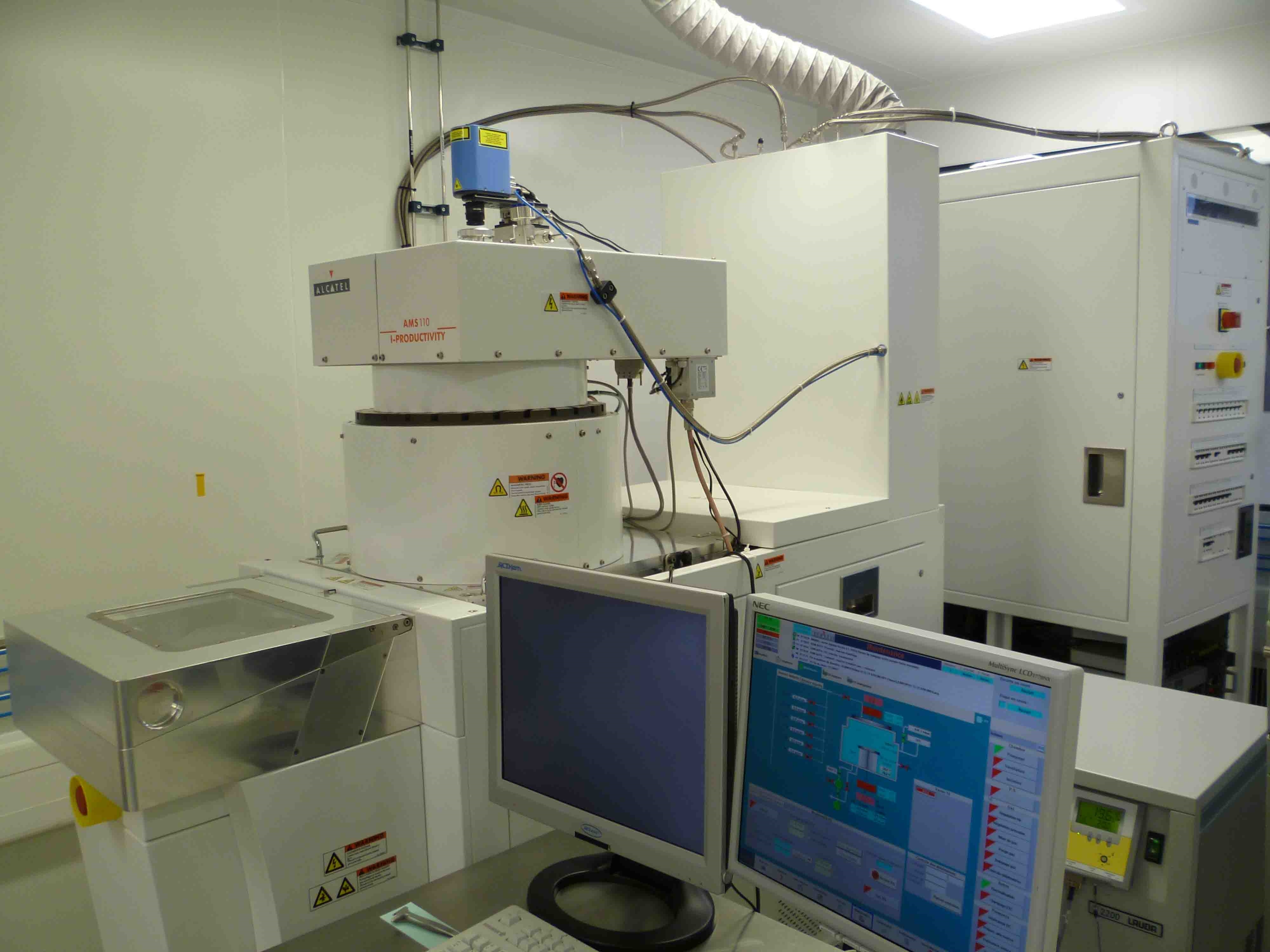

Used ADIXEN AMS 110 #9200290 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9200290

Wafer Size: 4"-6"

Vintage: 2007

DRIE Etcher, 4"-6"

ICP Etching system for silicon

Includes:

Vacuum pumps, chiller

Process chamber:

Bosch licence

Substrate holder in ESC finger clamping version+LAUDA Chiller type RK8CP

Wafer centering kit

Source power supply: 3 kW RF

Bias power supply: 300 W LF

Chamber primary pump: ADIXEN Dry pump (ADP 122)

Chamber maglev turbo molecular pump: ADIXEN ATH 1600 MT

DN 200 Throttle valve VAT 61 series

Gas lines:

SF6/1000 sccm

C4F8/400 sccm

O2/200 sccm

Load-lock:

Single wafer manual vacuum load lock including:

One cover (Aluminium and plexiglass)

Manual wafer transfer arm: Load-lock and process chamber

Control module:

Allen bradley PLC and industrial PC with its UPS

User interface: Windows 2000

Separate electrical cabinet including main control panel

RF/LF generators and PLC

AMS 100 system is delivered with 10m cable:

Electrical cabinet

Process module

Documentation:

Users / Maintenance manual on CD-ROM and PC hard disk

Electrical schematics on standard paper

Components manual on CD-ROM

Options:

Basic structure:

Heated liner installed in source chamber

Automatic load lock

Pumping station: Heated valve VAT 65 series and by-pass valve

End point detection:

Digilem 200: IR (905nm) Camera

Substrate holder 100 mm kit: 4" Additional ESC pin

2007 vintage.

ADIXEN AMS 110 etcher/asher is an advanced thermal processing system designed for a wide range of etch and ashing applications. It features a high performance combination of gas delivery, temperature control, and physics-of-flight capabilities, making it an ideal tool for the most challenging etching and ashing processes. AMS 110 provides superior etch and ashing results, with fast and repeatable processing thanks to its advanced high-performance inert-gas nozzles and temperature control. The modular design of the etcher/asher allows for a wide range of configurations based on the specific needs of the user. The system provides up to four independent gas control channels, allowing users to process with multiple gases simultaneously. Each channel is provided with independent flow and temperature control, allowing the user to optimize process results. Additionally, multiple targets can be processed simultaneously, allowing multiple users to process many similar parts or many dissimilar parts in parallel. The innovative physics-of-flight technology utilized by ADIXEN AMS 110 helps to shape the plasma and evenly cover the targets, resulting in uniformity and repeatability in processing. The etcher/asher is also equipped with an optional high current (up to 100 amps) ICP power source for etching and ashing applications that require higher precision. The user-friendly interface provides precise control of the etcher/asher with an intuitive, graphical programming interface for easy setup. The software for AMS 110 also includes a host of advanced features, such as process monitoring, automated gas exchange, and recipe-based production. The user can also set multiple hierarchal user levels, allowing each user to be given access to the specific functions they need. Overall, ADIXEN AMS 110 etcher/asher is an innovative system designed to deliver high-performance, repeatable etch and ashing results while meeting a wide range of needs for multiple users. Its combination of temperature control, gas delivery, and physics-of-flight capabilities makes it an ideal tool for the most challenging etching and ashing processes.

There are no reviews yet