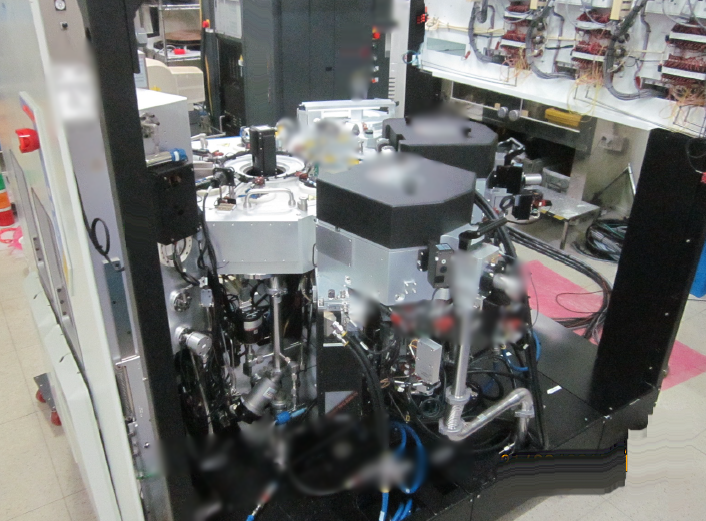

Used AMAT / APPLIED MATERIALS Centura DxZ #9093320 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9093320

CVD System, 8"

(3) Chambers: DxZ

Ch. A:

MANOMETER:100/2

HEATER: AL

CLEAN METHOD: AE 2000-2V

Pressure METHOD: Direct drive throttle valve

CH. B:

MANOMETER:100/2

HEATER: AL

CLEAN METHOD: AE 2000-2V

Pressure METHOD: Direct drive throttle valve

CH. D:

MANOMETER:100/2

HEATER: AL

CLEAN METHOD: AE 2000-2V

Pressure METHOD: Direct drive throttle valve

1st Monitor: Through the wall

2nd Monitor: Stand alone

Narrow body loadlock

HP Robot

OTF

Valves: Unit MFCs

Filters: Milipore

Regulators: Veriflo

System cabinet exhaust: Top

Single line drop

Gas Pallet Config:

CH.A SIZE MODEL CH.B SIZE MODEL CH.D SIZE MODEL

SiH4 500sccm Stec MFCs SiH4 500sccm Stec MFCs SiH4 500sccm Stec MFCs

NH3 200sccm Unit MFCs NH3 200sccm Unit MFCs NH3 200sccm Unit MFCs

NF3 1 Slm Unit MFCs NF3 2 Slm Unit MFCs NF3 1 Slm Unit MFCs

N2O 500sccm Unit MFCs N2O 500sccm Unit MFCs N2O 500sccm Unit MFCs

N2 5 Slm Unit MFCs N2 5 Slm Unit MFCs N2 5 Slm Unit MFCs

Process: nitride deposition (Nit. Pass.)

1996 vintage.

AMAT / APPLIED MATERIALS Centura DxZ 2.5MW PECVD Reactor is designed for deposition of advanced materials such as amorphous, microporous, silicon and carbon nitride. It is highly configurable and provides deposition solutions for a wide variety of applications. AMAT Centura DxZ reactor is a parasitic parallel-plate reactor that uses magnetized plasma to create a uniform and persistent flow of deposition gases. This allows for optimized deposition rates and conformal coating on all surfaces. The reactor is designed to deposit layers with thicknesses from 2 nanometers to 8 micrometers. The PECVD process provides superior step coverage on various geometries while maintaining low thermal loads. APPLIED MATERIALS Centura DxZ reactor is equipped with a source power of up to 2.5 MW, allowing for high deposition rates. The plasma density is adjustable, allowing for optimal incorporation of different gas combinations. It also features two separate gas feeds, allowing for independent control of the plasma parameters such as temperature, pressure, and doping. The operating pressure range of Centura DxZ reactor is between 0.01 mbar and 4 mbar, allowing for a variety of processes including etching and deposition. The temperature range is adjustable between 200 and 900 degrees Celsius, allowing for different process recipes. The reactor can also be configured for stable and repeatable process control, providing consistent results time after time. AMAT / APPLIED MATERIALS Centura DxZ is designed for safe and reliable operation. It is equipped with several safety systems, such as an on-board purge system and temperature sensing. This allows for safe operation and the prevention of potential contamination due to the presence of residual gases. Overall, AMAT Centura DxZ reactor is an advanced tool for the deposition of a wide range of advanced materials for different applications. Its wide operating temperature and pressure ranges, combined with high power and a stable and repeatable process control make it a flexible and reliable deposition solution.

There are no reviews yet