Used LAM RESEARCH 2300 Exelan #9158591 for sale

URL successfully copied!

Tap to zoom

ID: 9158591

Wafer Size: 12"

Etcher, 12"

EFEM:

Load port (1): Yes

Load port (2): Yes

Load port (3): Yes

Atm robot: No

Wafer alignment: Yes

Power control rack:

AC Rack: No

Rear user interface monitor: No

Robot controller: No

P/C: No

Vacuum TM:

Airlock (Right): Yes

Airlock (Left): Yes

VTM Robot: No

TM / PM Facility lines: Yes

Slop valve load lock (Right): Yes

Slop valve load lock (Left): Yes

Vacuum TM: Part No

Inner door Assy (Air lock Right): 853-007861-002

Inner door Assy (Air lock Left): 853-007861-003

Inner door Assy (PM2): 853-007859-002

Inner door Assy (PM3): 853-007859-004

Inner door Assy (PM4): 853-007859-923

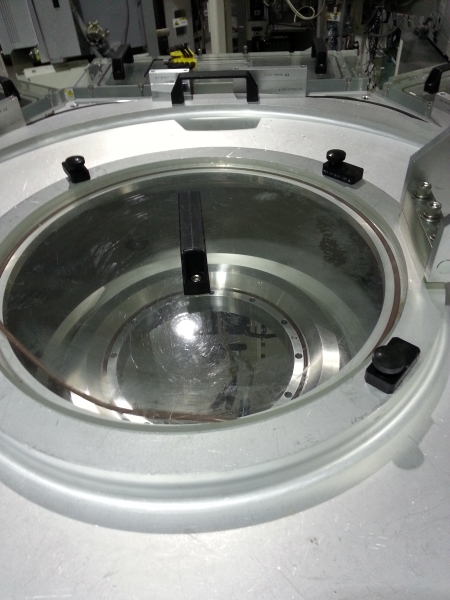

Process module:

PM2:

2300 Exelan:

Model no: Exelan 2300

Vintage: 2003

VAT Pendulum valve: Yes

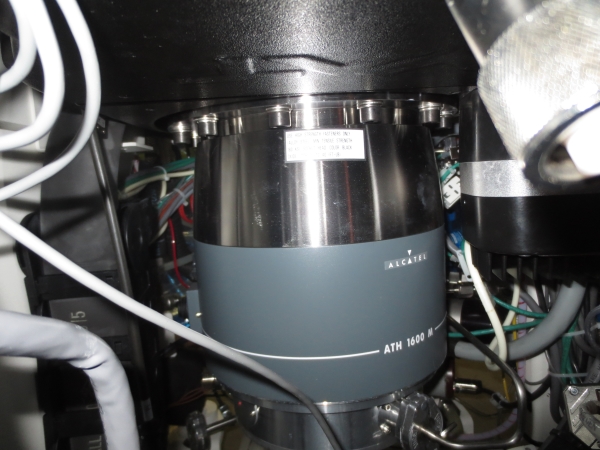

Turbo pump (ATH 1600M): Yes

Turbo controller: Yes

WAP Manometer:

Model no: 628B01TED1B

OES Spectrometer: Yes

AC Box: Yes

Fore line manometer: Yes

Turbo pump fore line isolation valves, manometers: Yes

Interlock PCB: Yes

VME Assembly: Yes

DC Power: Yes

BICEP Power supply / RF Match: Yes

He cooling / Lift box: Yes

RF Cart:

RF System A/C power: Yes

Generator (TCP): Yes

Generator (BIAS): Yes

Gas box(GIB): Yes

MFC 1_C4F8: Yes

MFC 2_N2: Yes

MFC 3_O2: Yes

MFC 4_CF4: Yes

MFC 5_O2: Yes

MFC 6_CHF3: Yes

MFC 7_AR: Yes

MFC 8_: Yes

MFC 9_O2: Yes

MFC 10_O2: Yes

MFC 11_CH2F2: Yes

MFC 12_C3F8: Yes

RPDB Power box: Yes

PM3:

2300 Exelan:

Model No: Exelan 2300

Vintage: 2003

VAT Pendulum valve: Yes

Turbo pump (ATH 1600M): Yes

Turbo controller: Yes

WAP Manometer:

Model no: E28B-23743

OES Spectrometer: Yes

AC Box: Yes

Fore line manometer: Yes

Turbo pump fore line isolation valves, manometers: Yes

Interlock PCB: Yes

VME Assembly: Yes

DC Power: Yes

BICEP Power supply / RF Match: Yes

He cooling / Lift box: Yes

RF Cart:

RF System A/C power: Yes

Generator (TCP): Yes

Generator (BIAS): Yes

Gas box (GIB): Yes

MFC 1_C4F8: Yes

MFC 2_N2: Yes

MFC 3_O2: Yes

MFC 4_CF4: Yes

MFC 5_O2: Yes

MFC 6_CHF3: Yes

MFC 7_AR: Yes

MFC 8_: No

MFC 9_O2: Yes

MFC 10_O2: No

MFC 11_CH2F2: No

MFC 12_C3F8: No

PM4:

2300 Exelan:

Model no: Exelan 2300

Vintage: 2003

VAT Pendulum valve: Yes

Turbo pump (ATH 1600M): Yes

Turbo controller: Yes

WAP Manometer:

Model no: E28B-23747

OES Spectrometer: Yes

AC Box: Yes

Fore line manometer: Yes

Turbo pump fore line isolation valves, manometers: Yes

Interlock PCB: Yes

VME Assembly: No

DC Power: Yes

BICEP Power supply / RF Match: Yes

He cooling / Lift box: Yes

RF Cart:

RF System A/C power: Yes

Generator (TCP): Yes

Generator (BIAS): Yes

Gas box (GIB): Yes

MFC 1_C4F8: Yes

MFC 2_N2: Yes

MFC 3_O2: Yes

MFC 4_CF4: Yes

MFC 5_O2: No

MFC 6_CHF3: Yes

MFC 7_AR: Yes

MFC 8_: No

MFC 9_O2: Yes

MFC 10_O2: No

MFC 11_CH2F2: No

MFC 12_C3F8: No.

LAM RESEARCH 2300 Exelan is an etcher/asher that is designed to meet the needs of advanced semiconductor production. It is capable of performing a range of etching and etching-related operations such as plasma etching, wet etching, laser ablation, and oxygen bombardment. The unit is built for reliable, repeatable performance and can process up to 9-inch wafers with the latest process technologies. Equipped with a dual chamber, the Exelan can process different wafers independent of each other, with each chamber operating under separate conditions. The Exelan's Process Control Optimization (PCO) feature ensures optimal plasma etch conditions. PCO monitors the plasma as it is processed and adjusts the parameters to maintain the desired specifications. This helps prevent defects and scrap and helps maintain process stability. The Exelan's motion system is engineered for quiet and accurate wafer transport during the etch process. Its Quiet Motion technology uses ultra low noise motor design and advanced motor drive algorithms. Its Wyko vision system is used to monitor the wafer position in real-time and is equipped with vision based alignment to ensure accurate placement of the wafer to within 0.1 micron (1 millionth of a meter) accuracy. The Exelan's Plasma-Enhanced Command Protocol (PECP), a powerful software suite, allows for rapid reaction to process changes and improved production performance. PECP consists of a suite of computers, programs and diagnostics that are used to monitor, control, diagnose and optimize the Exelan's performance. It can be set up to run custom recipes and can even be integrated with existing automation systems. The Exelan is designed with safety in mind providing hermetically sealed exhaust ports and multiple safety interlocks that are designed to work with local site interlock systems. Additionally, it is designed to reduce maintenance costs and decrease downtime. All critical components are designed for easy serviceability from the front panel and accessible components. The Exelan is a reliable and versatile etcher/asher solution that is optimized to meet the high standards of advanced semiconductor production. Equipped with advanced features and technologies, the Exelan ensures consistent performance and reliable operation.

There are no reviews yet