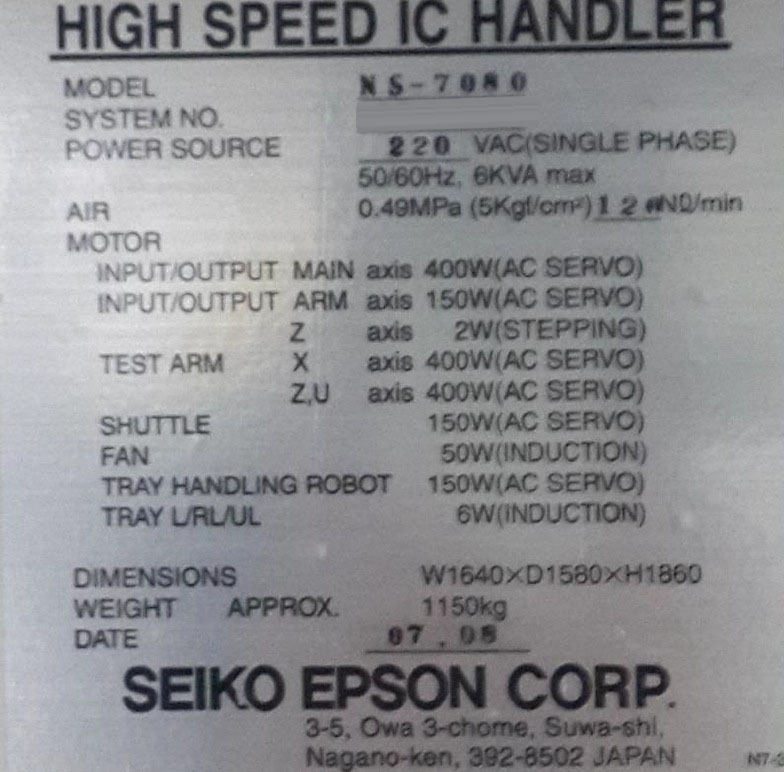

Used SEIKO / EPSON NS 7080 #9098596 for sale

URL successfully copied!

Tap to zoom

ID: 9098596

Vintage: 2007

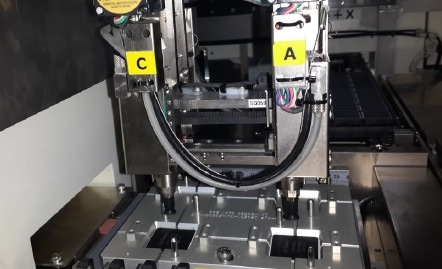

Octal site handlers

Includes:

SLK Kit

Temperature: Room / Hot (Chamber type)

Test mode:

Single

Dual: Pitch between socket, 80 mm

Quad: Square type socket, 80 mm x 60 mm

Octal: 2x4

Tester interface: DIO, GPIB, RS232

Site testing / Layout: Single center, 1x2, 1x4, 2x2, 2x4

Input / Output arms: Variable open / Close pitch

Tester docking height: Standard height

Maximum contact force: 80 kgf

Hotplate

Contact pressure

Temperature range: ~130°C

(3) Ionizers

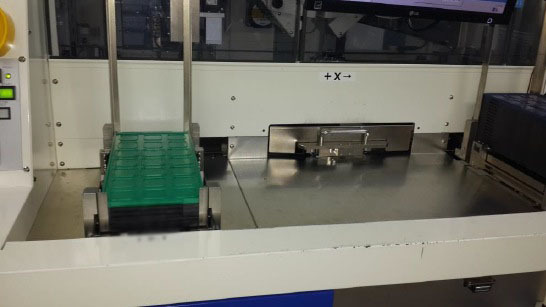

Tray transfer arm: Vacuum

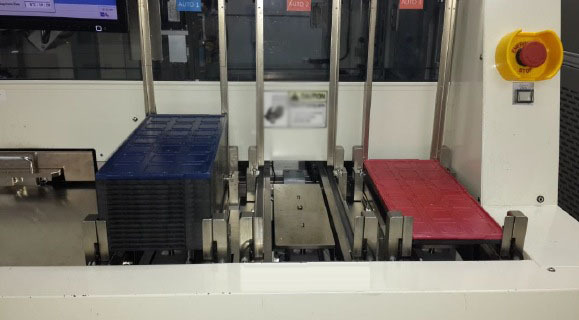

Output trays: (3) Fixed and (3) Auto

Vacuum pump

Pitch for 2x2 socket layout kit, 80 mm x 60 mm

Pressure: 0.49 MPa (5 kgf/cm2), 120 NL/min

Options:

Chamber cooling fan

Input shuttle floating sensor

No retrofit kit

Power supply: 220 VAC, 50/60 Hz, Single phase

2007-2008 vintage.

SEIKO / EPSON NS 7080 is a highly advanced production handling equipment designed for the industrial automation of pick and place operations. It is a capable machine designed with maximum efficiency and accuracy in mind and is capable of handling a wide range of products. The machine is designed with a conveyor belt to move products along for identification, sorting, and placement. The mechanism is designed with accuracy and consistency in mind and is equipped with positional sensors and vision systems to detect, locate, and transfer parts to be placed at the right position. SEIKO NS 7080 offers simple setup and user-friendly operation, allowing for easy and intuitive operation. The system is equipped with a color touch panel display and easy to use touch keys, allowing for greater customization of the machine's settings. Additionally, EPSON NS7080 has a built-in PLC unit with onboard advanced safety features to ensure proper operation, including end of arm sensors and deadman switches. The machine is designed to accommodate medium to high volume production runs, with its modular design. EPSON NS 7080 features several interchangeable heads, allowing for greater customization and allowing the handling of multiple product types with minimal setup time demands. The machine has a total belt width of 29.9 in (76 cm), a cycle rate of up to 170 parts per minute, a movement range of 680 mm in X/Y coordinates and has a placement accuracy of 0.04 in. (1.0 mm). NS 7080 offers superior reliability, durability, and flexibility, making it ideal for a range of industrial applications. The machine is designed to work in conjunction with SEIKO C-Series robots and is equipped with advanced vision guidance, tracking, and handling capabilities to ensure accuracy for a variety of tasks. Furthermore, the tool is compatible with numerous industry protocols, allowing for easy integration into existing production lines and systems. Overall, NS7080 is a highly capable and efficient handling asset designed for medium to high volume production runs. Its user-friendly features make it easy to use and customize, while its advanced vision systems and tracking capabilities make it exceptionally reliable for a wide range of tasks. The model's modular design ensures flexibility and its compatibility with other industry protocols enables quick integration into existing production lines.

There are no reviews yet