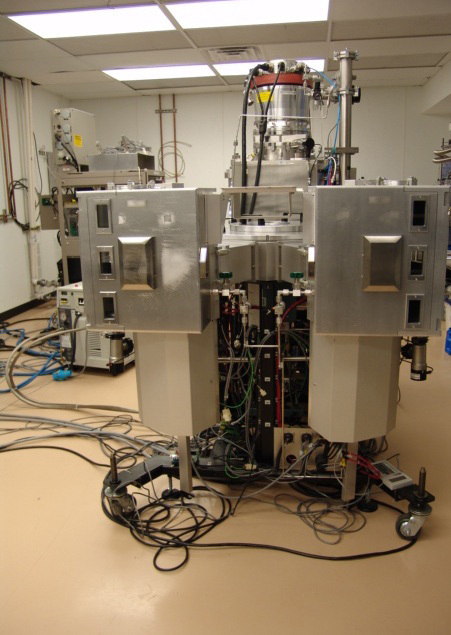

Used VEECO / DEKTAK RF350 C2 IBE #9124214 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9124214

Wafer Size: 6"-8"

Vintage: 1997

Ion beam etcher, 6"-8"

Process modules transport module systems include:

BROOKS Automation robot wafer handler system

Loadlock A & B

Electronics cabinet contains:

(2) APC 450 UPS

Raritan compu-switch

Industrial PC

(2) LEYBOLD INFICON IG3 Vacuum gauge controllers

LEYBOLD NT20 Turbovac controller

(2) SORENSEN DCS60-18 Power supplies

SORENSEN DCS20-150 Power supply

SPELLMAN SL300 Power supply

SPELLMAN SL1200 Power supply

Process modules include:

LEYBOLD MAG2000 Turbo pump & controller

CTI Onboard cyropump with fastregen sputtering module

CTI 9600 Compresser

RFPP AM-10/20 Auto matching network

ADVANCED ENERGY RF10M / RF20M Power supply

CTI Onboard controller RF matching network monitor

ADVANCED ENERGY RF-20MWC RF Generator

Main power distribution panel: 208V,100A

1997 vintage.

VEECO / DEKTAK RF350 C2 IBE is an ion milling equipment which is designed for the preparation and characterization of surfaces of advanced materials. It is suitable for use in metrology, failure analysis, and planarization of thin films, as well as for many other applications. The system utilizes a focussed beam of energetic ions to mill away the surface of the material. Payloads of up to 350mm can be accommodated, allowing for samples of a wide range of sizes and shapes to be milled. The unit has an automated control machine, which enables the user to define the desired parameters for the milling process. A computer-controlled interface allows for easy manipulation of the ion beam in two planes of motion. It also allows for complex milled features to be created on the surface of the sample. The tool is equipped with a high resolution digital image/video asset for acquiring images/video of the milled surface. The model has advanced safety features, such as an interlock equipment which prevents the system from operating when the chamber is opened. It also contains an emergency stop button. The unit is in compliance with industry standards for environmental safety and energy efficiency. The gas delivery machine is designed to provide precise control of gas flow and particle production, and ensure minimal waste. Additionally, the tool utilizes an advanced water cooling asset which minimizes the power consumption and reduces noise levels. The model also integrates a fully automated plasma cleaning equipment. This allows for the removal of surface contamination prior to milling. It is also capable of chemical cleaning of the chamber walls to ensure the quality of the surface of the sample being milled. Overall, VEECO RF350 C2 IBE is designed to provide an efficient and accurate surface preparation and characterization system, while also providing maximum safety and protecting the environment. The unit is an ideal solution for various applications in metrology, failure analysis, and thin film planarization.

There are no reviews yet