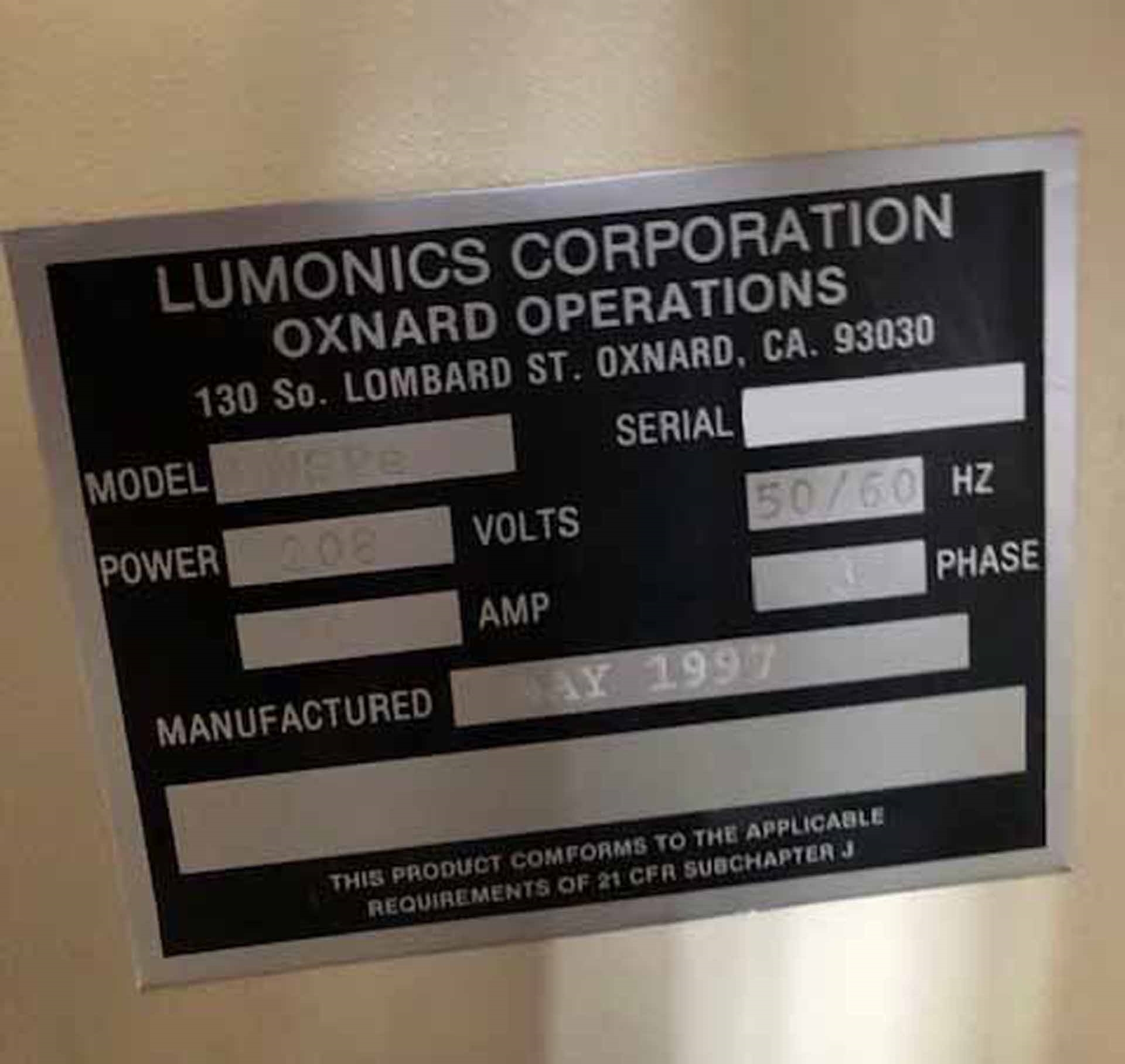

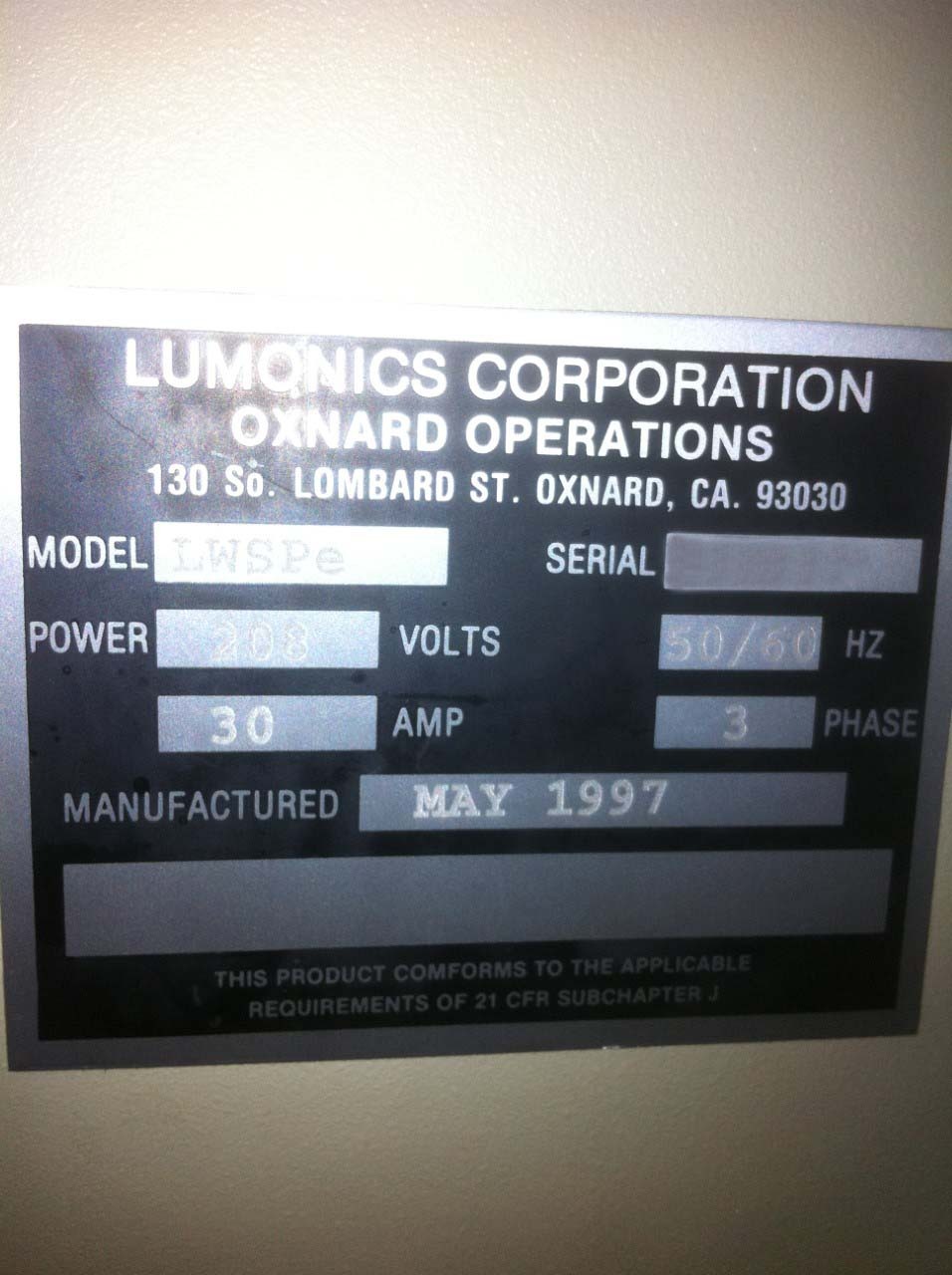

Used GSI LUMONICS Lightwriter SPe #149105 for sale

URL successfully copied!

Tap to zoom

ID: 149105

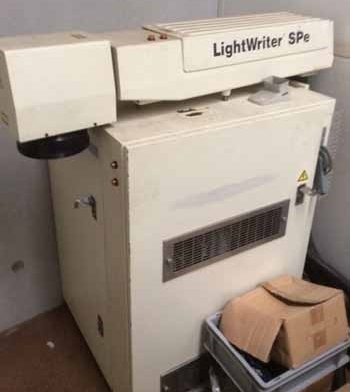

Laser marking systems

NEMA 12 Industrial packaging

Option: Air conditioning of electronics cabinet

YAG Laser, 50W Q-Switched

Programmable laser power

Marking head and optics:

Flat field lens, 4" x 4" (Post scan focus)

Options:

Flat field lens, 7" x 7" (Post scan focus)

Flat field lens, 2" x 2" (Post scan focus)

Distortion correction

LightWriter user interface terminal and control:

486-DX IBM OS/2 Based system

SVGA Color monitor

8 MB RAM memory: 33 MHz Clock

Single 1.4 MB 3.5" Floppy Disk Drive (FDD)

Hard Disk Drive (HDD): 200 MB

Mouse pointer

101-Key enhanced keyboard

Parallel printer port

RS-232 Port

Control and status panel (Constant)

Power control, laser power measurements

Closed loop pulse to pulse laser power control

Open loop laser power control

Voltage conversion transformer:

Option: 415-208 / 50 Hz

Option: 460-208 / 60 Hz 20 kVA

PM Chart drawing package

REXX Programming language

Option: Closed-loop water chiller

Laser head:

Type: YAG

Output power: 50 W

Laser wavelength: 1064 nm

Q-Switch mode: TEmoo to multimode

Q-Switch modulation: Continuous wave to 64 kHz

Marking specifications:

Typesetting:

Resolution:

Character height: 7" Maximum

Character width: 7" Maximum

Character spacing: 0" min, 3.2" Maximum

Line spacing: 0" min, 3.2" Maximum

Writing speed: Engrave - constant velocity

Character style: Adobe type 1 fonts, fonts and graphics

Special effects:

Circular marking:

Minimum diameter: 0.1"

Maximum diameter: 7.0"

Circular direction: Clockwise / Counterclockwise circular marking

Italics: Minimum 0° angle to maximum ± 60° angle

Field rotation: 90° Increments

Text rotation: -359.9° to 359.9° in 0.1° Increments

Serialization: Up to 9 serial numbers per marking job

Step and repeat:

Column and row spacing: 0.0" to 2.0"

Row columns: 1 to 99

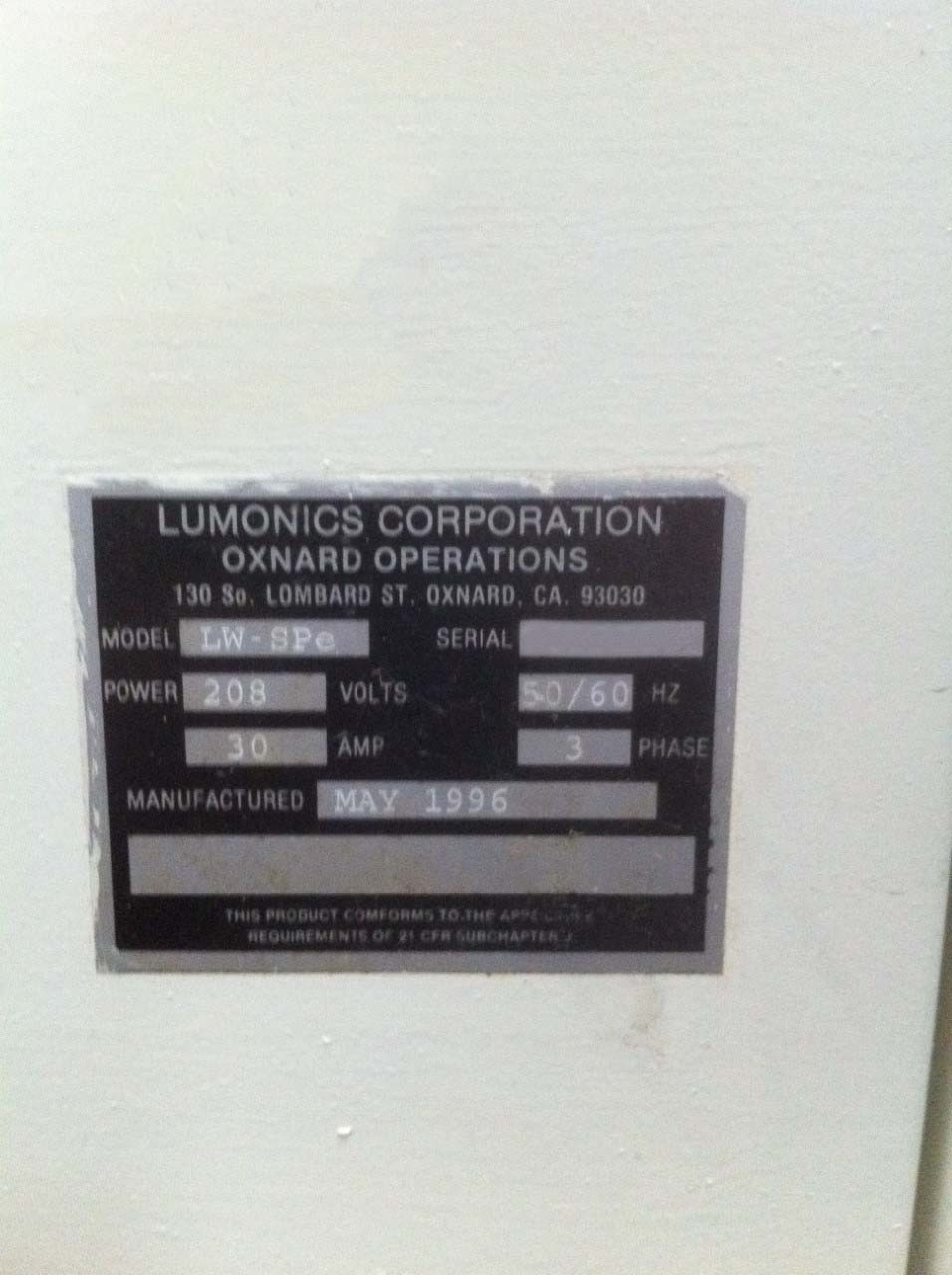

1996-1997 vintage.

GSI LUMONICS Lightwriter SPe is a marking machine designed to meet the needs of industrial production lines. This versatile laser marking equipment is robust, reliable, and delivers high-quality marks on a variety of materials. It is versatile and can be integrated into existing production systems to provide maximum efficiency and flexibility. Lightwriter SPe is a powerful and reliable marking system that can meet the highest standards in production marking. It is capable of moving and marking with speeds of up to 500 characters per second. The unit is capable of marking on a wide range of materials, from metals and plastics to ceramics, wood, and fabrics. Its laser power, speed, and accuracy ensure that it can meet even the most stringent production needs. GSI LUMONICS Lightwriter SPe offer a number of features to facilitate productivity and cost savings. It is extremely user-friendly, with a number of options for setting up and controlling the machine. It is equipped with a variety of sensors and feedback mechanisms, allowing it to adjust to a wide range of different production needs. Additionally, it features multiple laser lenses, allowing it to mark on a variety of surfaces without the need for an additional mirroring machine. The tool also features an integrated safety asset with a number of features designed to protect both the operator and the machine. This includes an optical replotting feature that allows the model to be brought back to the starting point should a marking problem occur. Additionally, it features a fire and smoke detection equipment that alerts operators should conditions warrant. Lightwriter SPe comes with a comprehensive suite of software, including a CAD/CAM control module for complete automation of the marking process. The system is compatible with a range of industry standard software, making it simple to integrate into existing systems. Additionally it includes powerful data management tools for analyzing production data and ensuring maximum efficiency in the marking process. GSI LUMONICS Lightwriter SPe comes with a strong, reliable construction and a sophisticated design that provides maximum performance and longevity. It is made from high-grade materials to ensure durability and reliability, even in the most challenging of production environments. It is backed by a comprehensive warranty and excellent customer service, giving operators the peace of mind that the unit will be able to last for many years.

There are no reviews yet