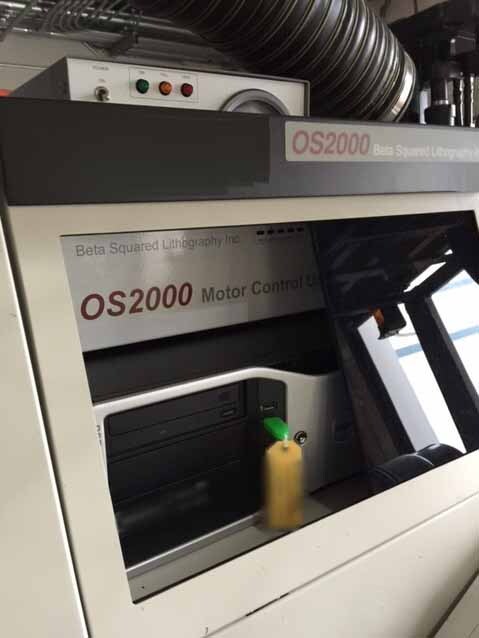

Used BSL / BETA SQUARED LITHOGRAPHY OS2000 #9174090 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9174090

Wafer Size: 4"-6"

Vintage: 2011

Mask aligner, 4"-6"

Specifications:

Resolution:

1.25 um lines and spaces, UV-4 (340-440nm)

1.0 um lines and spaces, UV-3 (300-350nm)

Machine to machine overlay:

+/- 0.25 um, 125 / 100 mm systems, 98% of data

+/-0.30 um, 150 mm systems, 98% of data

Machine to itself overlay: +/- 0.25 um, 98% of data

Throughput:

120 Wafers per hour, 125 / 100 mm systems

100 Wafers per hour, 150 mm systems

Depth of focus: +/- 6 um for 1.5 um lines and spaces

Focus stability: +/- 2.0 um over 6 days

Focus range: +/- 200 um, +/-450 um

Extended bellows chuck:

Partial Coherence: Variable, 0.37 to 0.86

Numerical Aperture: .167

Uniformity of Illumination: +/- 3.0%

Particle generation: <7 Particles per wafer pass (1.0 um or larger)

Pre alignment and first-level placement accuracy: +/-15 um

Footprint: 18.65 Square feet (1.732 square meter)

Electrical: 120 Vac at 10 Amps, or 240 Vac at 5 amps

Includes:

Several spare parts

User manuals

2011 vintage.

BSL / BETA SQUARED LITHOGRAPHY OS2000 is an advanced, process-driven mask aligner designed for ultra-precise microfabrication. It is an image-forming equipment that combines advanced optics and precise motion-control technology to create patterns on photoresist layers. This system is used to define circuit features, such as line widths, on electronic packages and create printed circuit boards for various components. BSL OS2000 unit consists of four major subsystems: the optical, motion-control, precision alignment, and ergonomic control machine. The optical tool consists of two laser beams that are used to generate a patterned image on the photoresist layer to create the desired pattern. The motion-control asset utilizes a multispindle motor to position the laser beams in precise locations. The precise alignment model utilizes a closed-loop servo to maintain the precise position of the laser beams. This ensures that the patterned image is accurately created on the photoresist layer. The ergonomic control equipment is designed to ensure user comfort, with an adjustable user interface and ergonomic controls. BETA SQUARED LITHOGRAPHY OS2000 offers excellent resolution and accuracy. It can achieve a pattern resolution of up to 50nm, and can accurately reproduce fine apertures and critical features. The system also offers high levels of linearity for high fidelity to original designs. Additionally, the unit can operate at a wide range of energies, from standard visible light to ultraviolet wavelengths, and has an adjustable wavelength range. The machine offers repeatability to ensure production quality control and throughput. OS2000 is an ideal choice for semiconductor and printed circuit board manufacturing. It combines the latest microfabrication techniques with the highest levels of accuracy, and it is easy to install and use. Its advanced automation capabilities can reduce the cost and time associated with mask aligner operations. Furthermore, it is highly reliable and produces consistent results.

There are no reviews yet