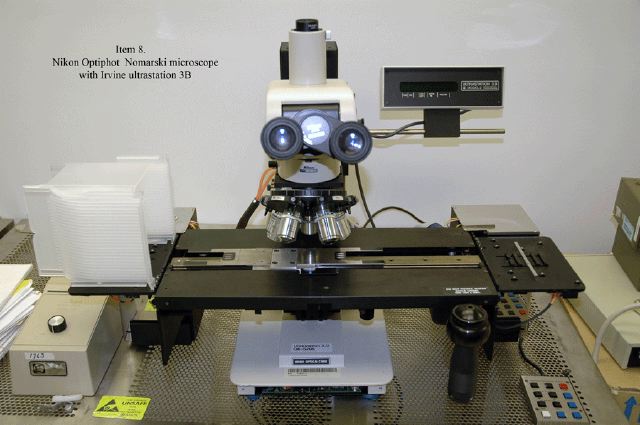

Used IRVINE OPTICAL Ultrastation 3B #7444 for sale

URL successfully copied!

Tap to zoom

ID: 7444

Wafer Size: 3", 4", 5", 6"

Wafer Inspection system with wafer loader, 3"-6"

Nikon optics including 10x, 20x, 40x, 60x, BD objectives

Bright field, dark field reflected light measurements

8"x15" stage

6"x6" stage movement.

IRVINE OPTICAL Ultrastation 3B is a powerful and highly accurate mask and wafer inspection equipment designed for a wide range of semiconductor applications. The ultrastation is composed of several modules, including a critical dimension (CD) measurement module, an automated defect inspection (ADI) module, an automated optical inspection (AOI) module, a wafer inspection module and a yield analysis module. To begin, the CD measurement module is equipped with advanced optics and features a new 0.7 micron accuracy, enabling rapid, precise and repeatable measurements. The multiple microscope objectives, a wide range of field of view and the integrated laser autofocus system make this a reliable, simple and versatile measurement tool. The ADI module, meanwhile, is a cross-sectional observation unit which enables users to quickly identify defects, according to their size and shape, in both wafer patterned areas and surrounding scribe lines. It features a multiple imaging option, allowing users to acquire data from up to two locations simultaneously. IRVINE OPTICAL ULTRASTATION 3 B's AOI module provides effective defect detection and classification, utilizing image comparison and advanced pattern matching algorithms. It can detect both microscopic and macroscopic defects, such as scratches, particles, stains and scratches, as well as bridging and opens. It is also capable of tracking and counting patterns, such as wires and vias. The wafer inspection module offers a full suite of metrology functions, including 2D pattern analysis, BGA analysis, pitch comparison analysis and integrated defect analysis. It is designed for scanning speeds up to 10X faster than traditional systems, and its automated systems provide precise and repeatable readings. Finally, the yield analysis module helps organizations to optimize the yield performance of their products. It offers advanced features, such as real-time yield tracking and quality control, as well as reporting capabilities. It also provides graphical displays that can be used to monitor defect trends and identify yield problems. In summary, the Irvine Optics Ultrastation 3B is an advanced mask and wafer inspection machine that blends performance, accuracy and a full suite of measurement and yield analysis tools. It is an ideal choice for organizations looking for a comprehensive, reliable and user-friendly device to meet the needs of their semiconductor applications.

There are no reviews yet