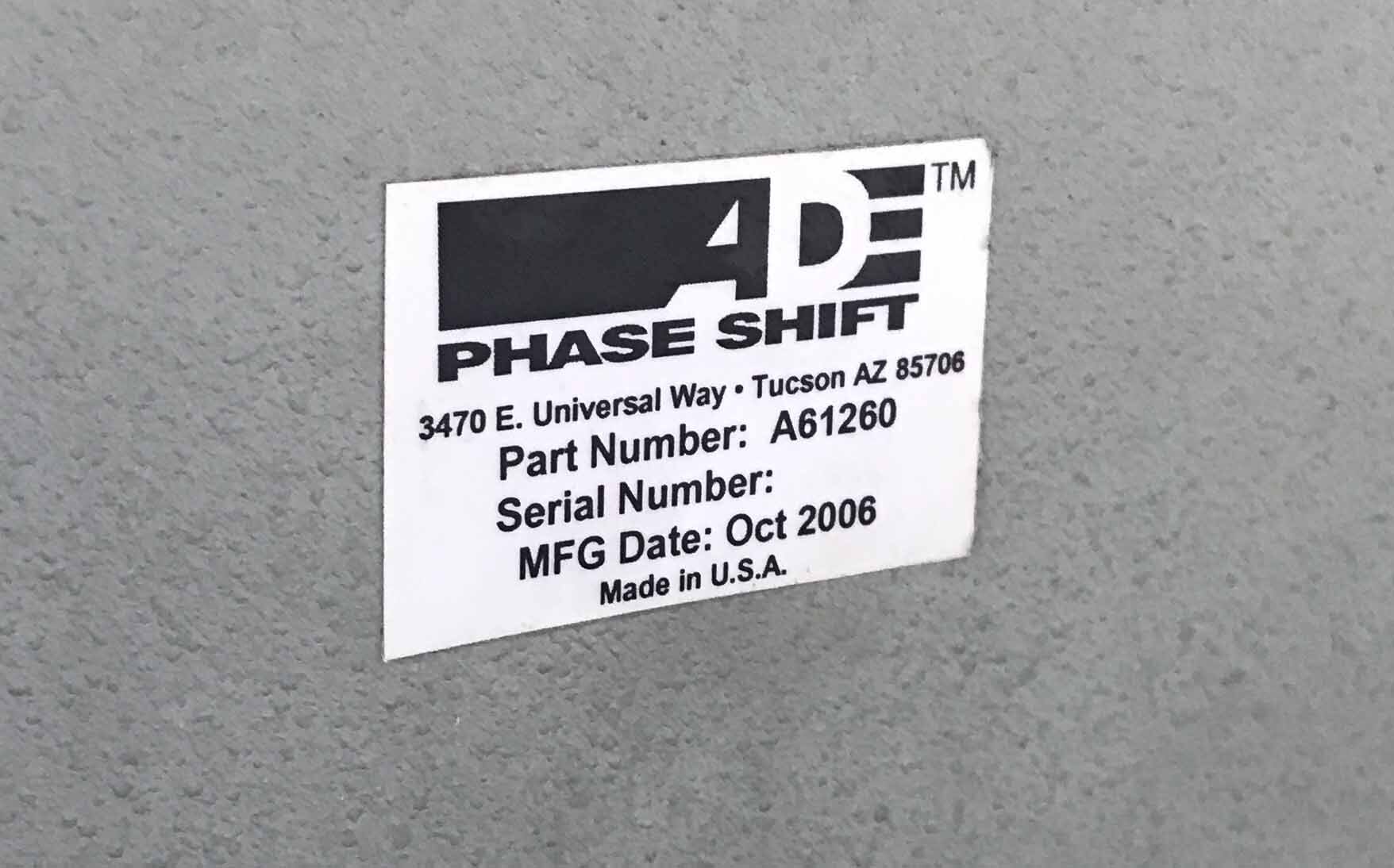

Used ADE / KLA / TENCOR MicroXAM #9189675 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ADE / KLA / TENCOR MicroXAM is a comprehensive wafer testing and metrology equipment that provides fast and reliable analysis of the properties of wafers used in semiconductor manufacturing. The system allows measurement and characterization of a variety of parameters of the wafer surface, including layer thickness, surface uniformity, and peak area density, as well as other parameters important for the manufacturing process. ADE MicroXAM is organized around an automated wafer handling platform. This platform allows for automated pick and place processing and precise wafer orientation for precise measurement of any of the wafer parameters. The automated wafer handler consists of two wafer carriers that are moved throughout the unit, allowing for the efficient testing, metrology and analysis of multiple wafers simultaneously. The machine also offers a suite of advanced metrology tools. These tools allow for non-contact optical measurement and characterization of the wafer's surface, such as layer thickness, peak area density, and surface uniformity. Advanced algorithms and software-controlled auto-focus help ensure accurate and repeatable measurement results. The tool also offers advanced digital imaging capabilities that allow for detailed imaging and analysis, as well as support for X-ray analysis and imaging. In addition, KLA MicroXAM is equipped with a suite of data acquisition and analysis tools, allowing for the processing and analysis of measurement results quickly and accurately. Additionally, the asset offers a variety of data visualization options that can help quickly identify and analyze critical component or wafer characteristics. TENCOR MicroXAM is an invaluable tool for ensuring consistency and accuracy of the semiconductor manufacturing process. By providing fast and reliable measurements and analysis of wafers, the model helps reduce costly manufacturing errors and maximize production yields.

There are no reviews yet