Used VEECO Gen II #9057008 for sale

URL successfully copied!

Tap to zoom

ID: 9057008

Vintage: 1984

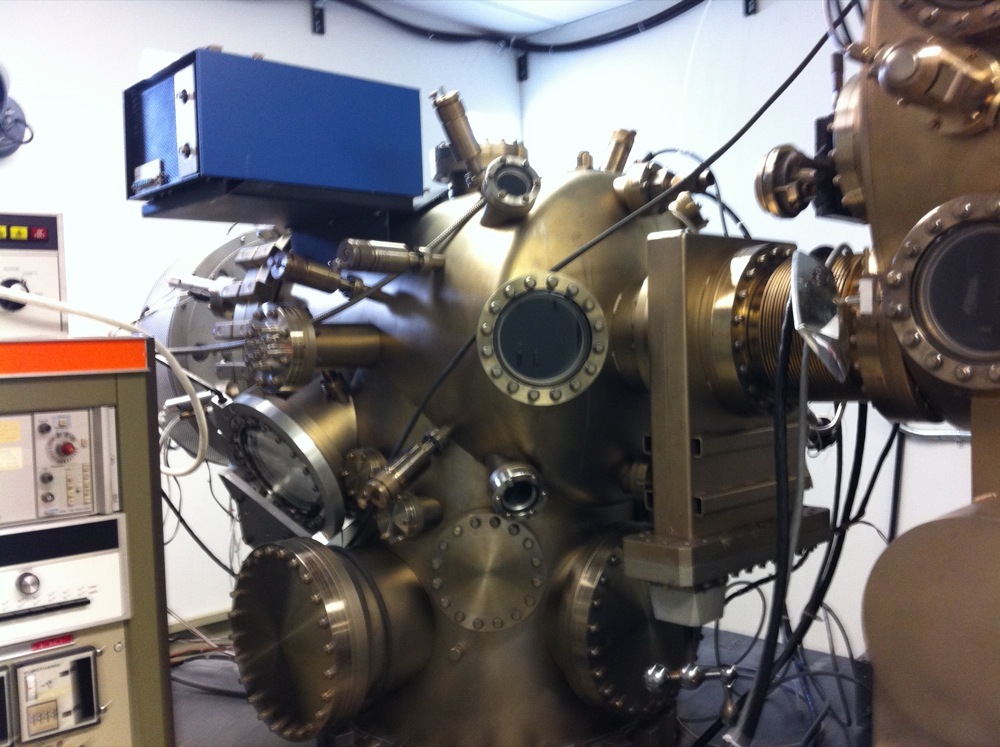

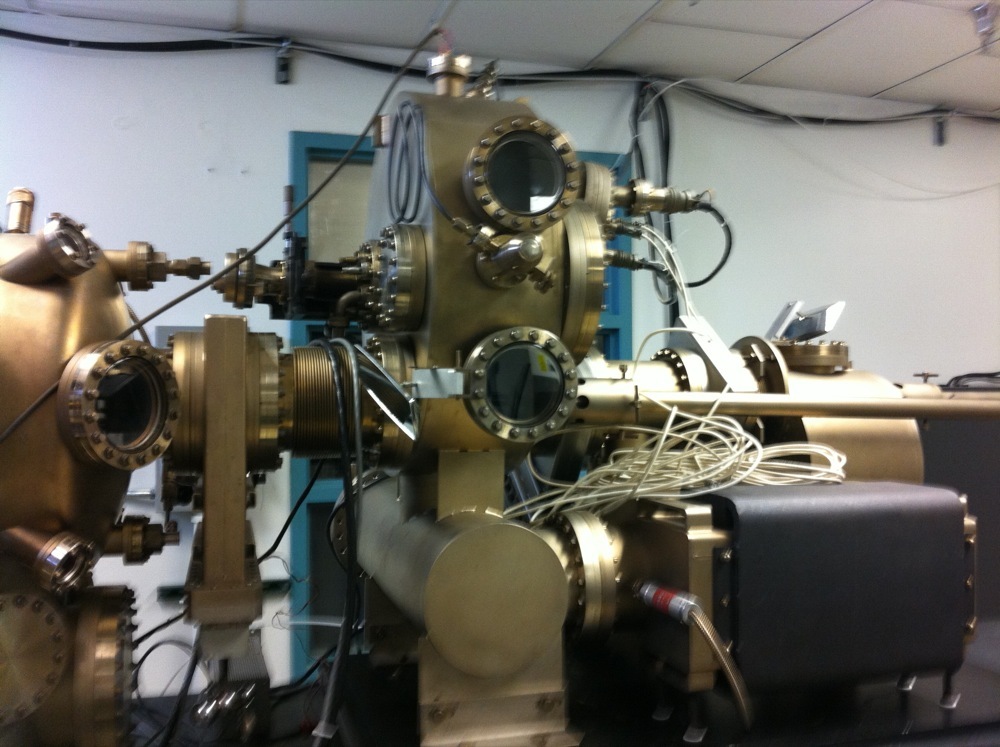

MBE Growth system

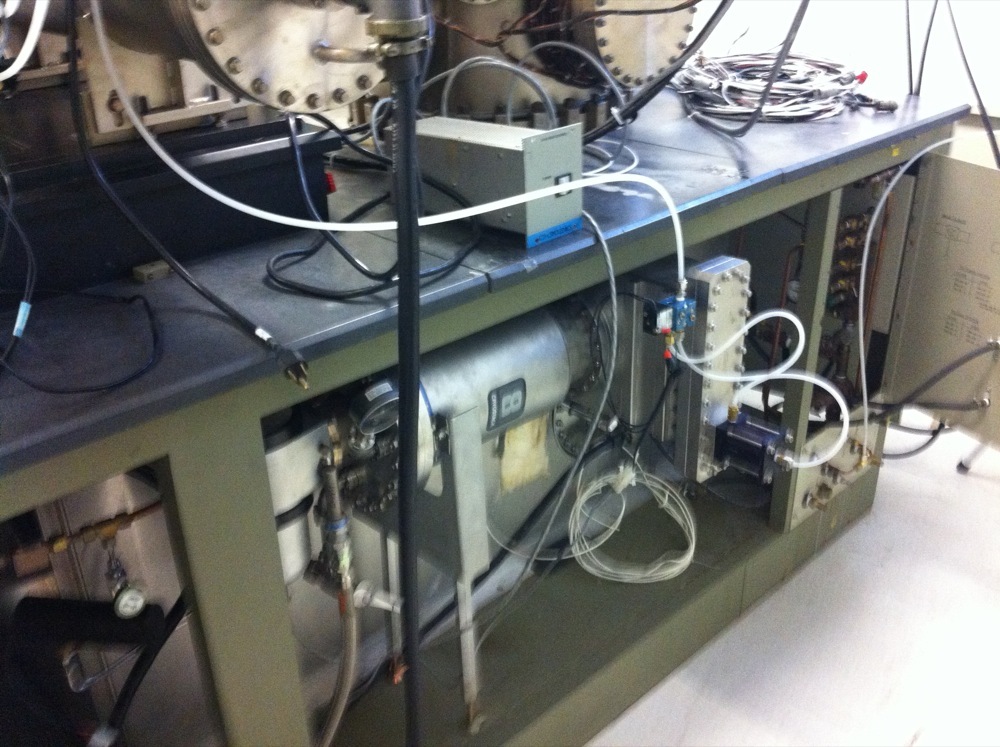

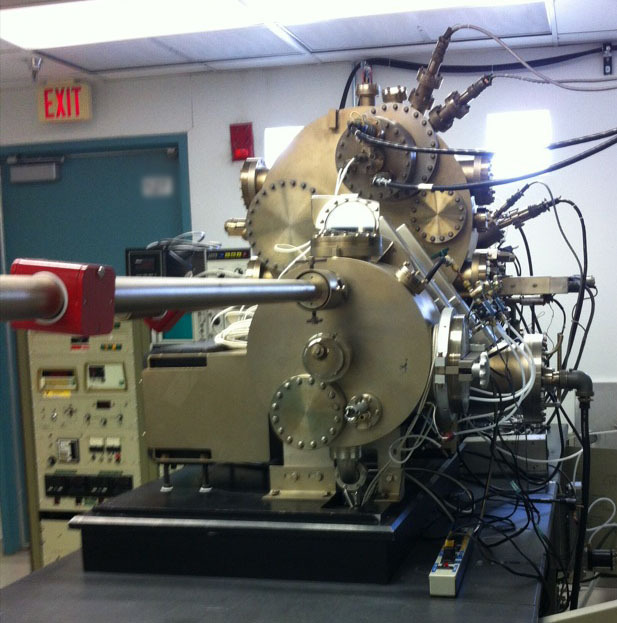

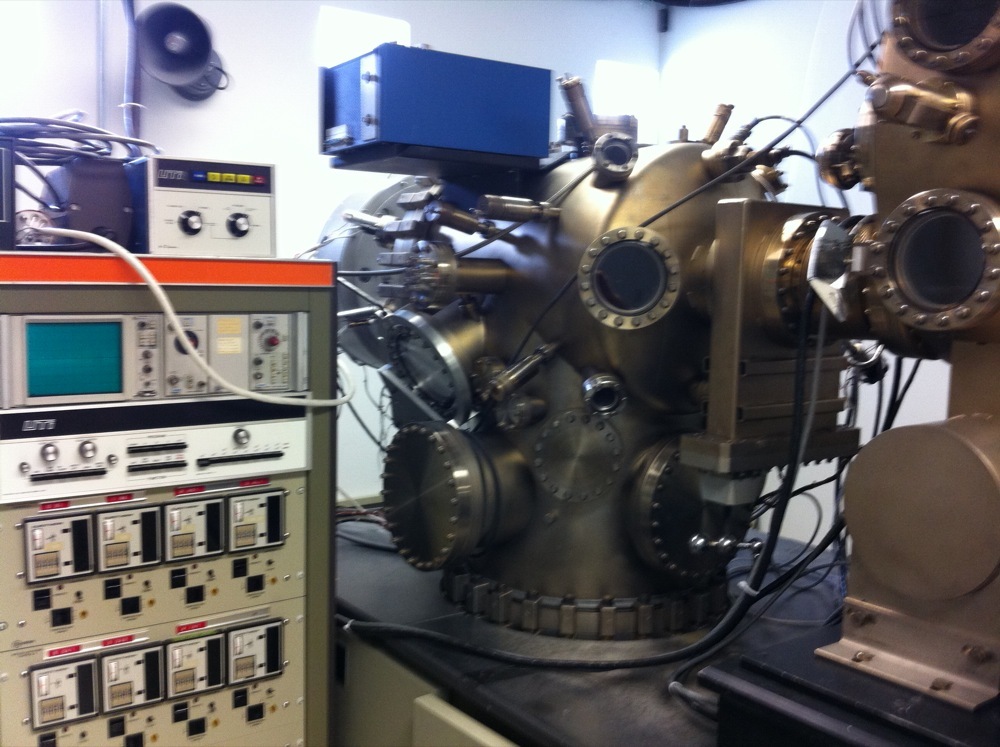

Wagon wheel prep chamber with auger analysis

Auxiliary chamber

Growth chamber

Manual valve

Ion-pumped 4-effusion cell system

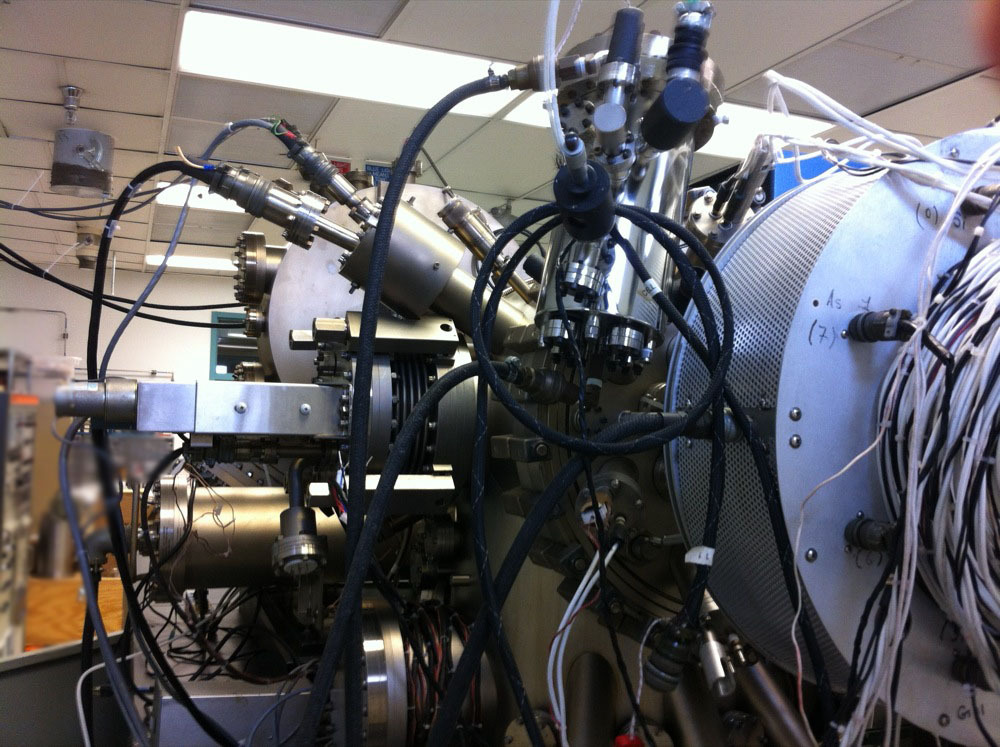

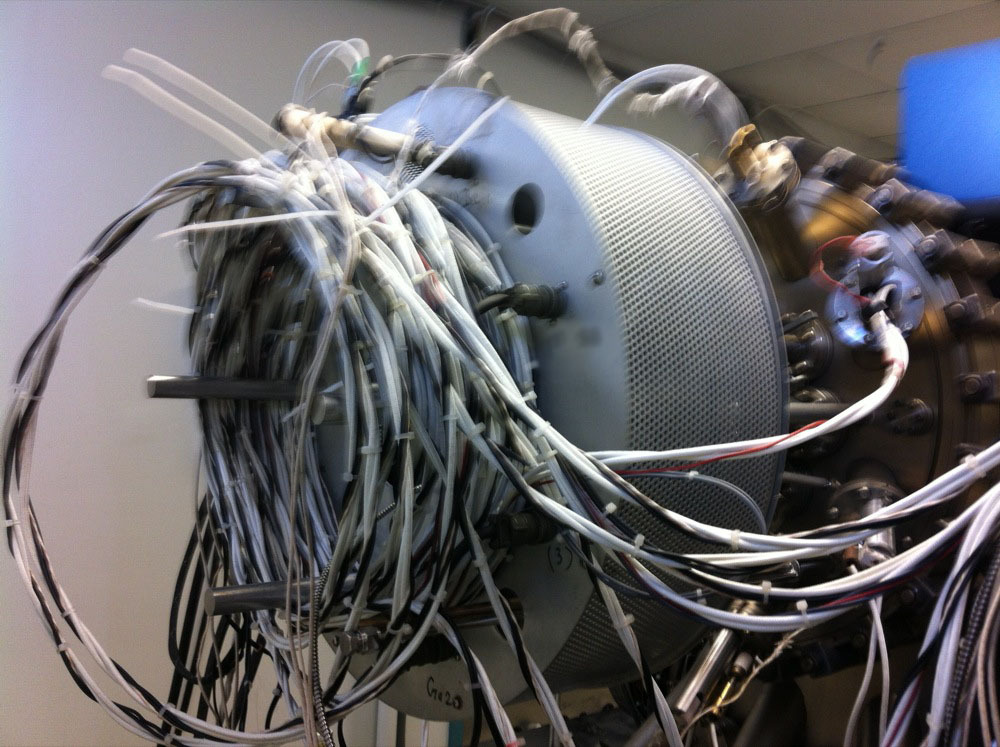

(8) Effusion cells, 2"

(4) Upward-looking effusion cells

All GaAs: InALGaAs based materials with Si and Be dopant sources

(3) Ion pumps at base

(2) Sorption pumps

Functional RHEed and QMS

Spare parts and effusion cells available

No phosphorous deposited

6-Wafer load lock

O2 Plasma source

H2S Cracker cell

H2S3 Cracker cell

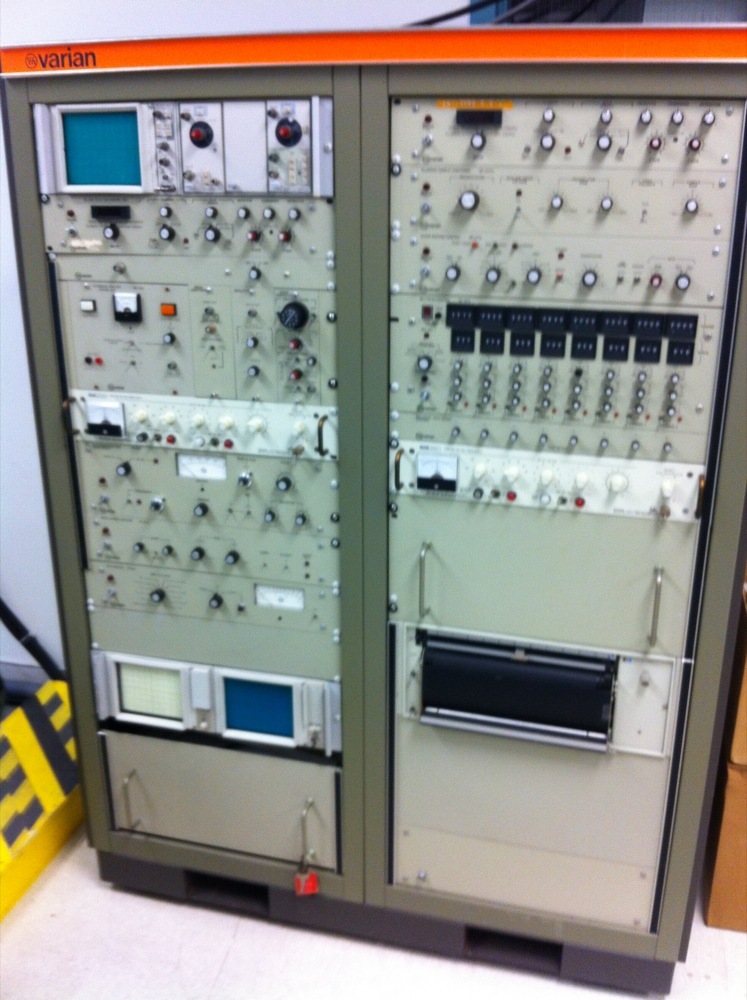

EUROTHERM Temperature controller

Operation system and computer

1984 vintage.

VARIAN / VEECO GEN II is a molecular beam epitaxy (MBE) equipment optimized for producing a wide range of optoelectronic and electronic materials. It offers a state-of-the-art modular design that permits simple configuration changes. It is provided with an advanced control system that offers an enhanced control of process parameters. It has the ability to deposit a wide range of materials, including semiconductor materials such as gallium nitride (GaN), indium gallium arsenide (InGaAs), gallium arsenide (GaAs) and indium phosphide (InP), as well as metals such as gold and aluminum. In addition, the unit is capable of performing several advanced material deposition techniques such as ion beam assisted deposition (IBAD), where a specially designed ion beam is used to profile and form the material, adsorption-controlled deposition, a technique which ensures that material is only deposited on exposed surfaces, and metal-assisted chemical etching (MACE), an innovative technique that can be used to create a wide variety of nanostructure-based templates. VEECO GEN II machine is also equipped with several advanced diagnostic systems that can be used to monitor and evaluate the quality of the deposited material. These include in situ reflectometry and scanning electron microscopy images. The tool is also integrated with an automated wafer monitoring asset. This allows for real time wafer analysis and quality control, allowing for optimal material deposition performance. VARIAN GEN II model is also provided with several safety features such as arc detectors, gas concentration and detector monitors and a safety interlock equipment. The features are designed to maintain a high level of safety for both operators and researchers alike. GEN II system is a powerful and flexible platform for the production of optoelectronic and electronic materials. Its advanced control unit ensures that the process parameters are maintained for optimum material deposition performance. It has the ability to deposit a wide range of materials, which makes it suitable for many different applications. In addition, the machine is equipped with several advanced diagnostic systems, providing comprehensive analysis of material deposition quality, as well as numerous safety features.

There are no reviews yet