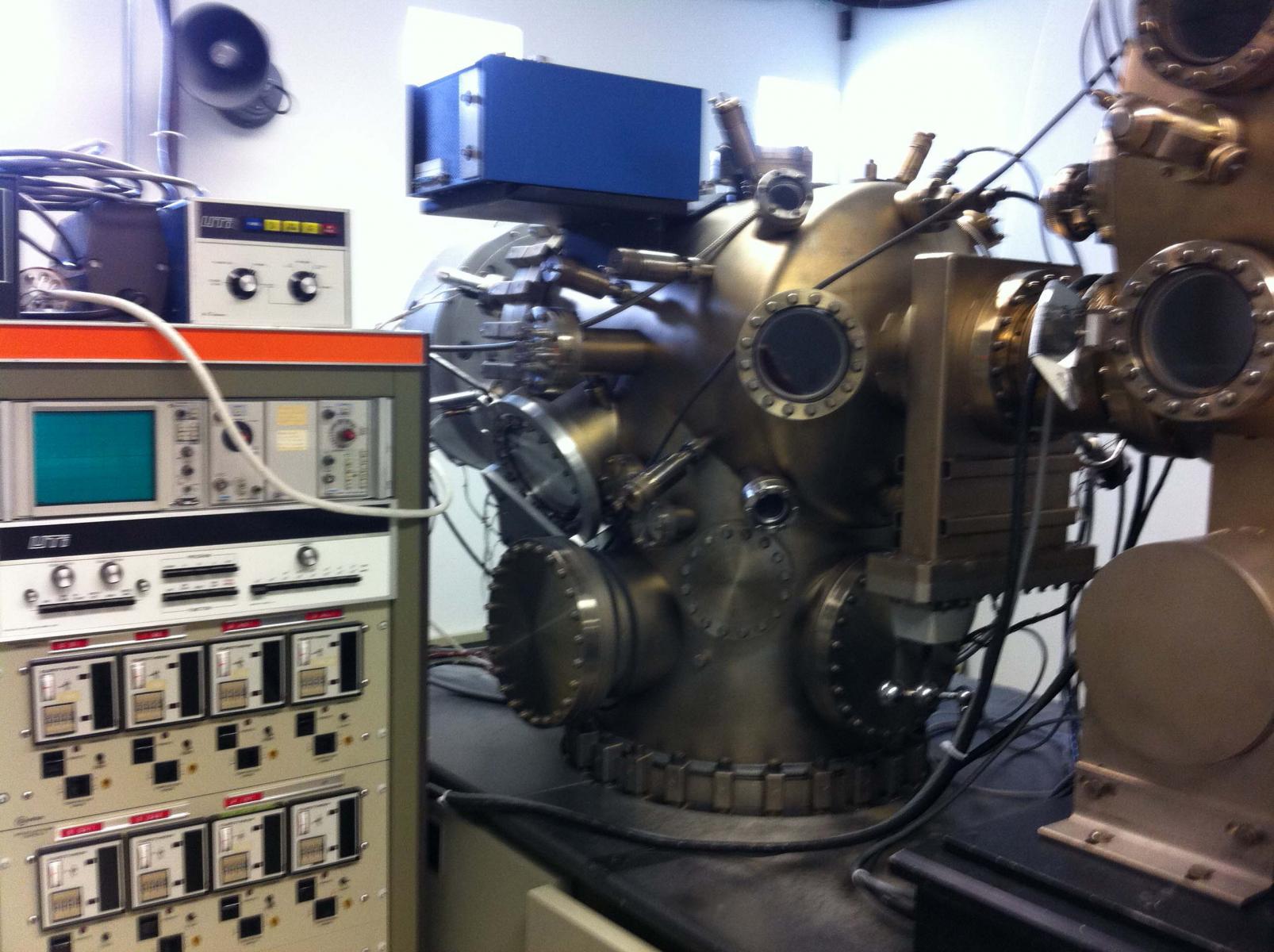

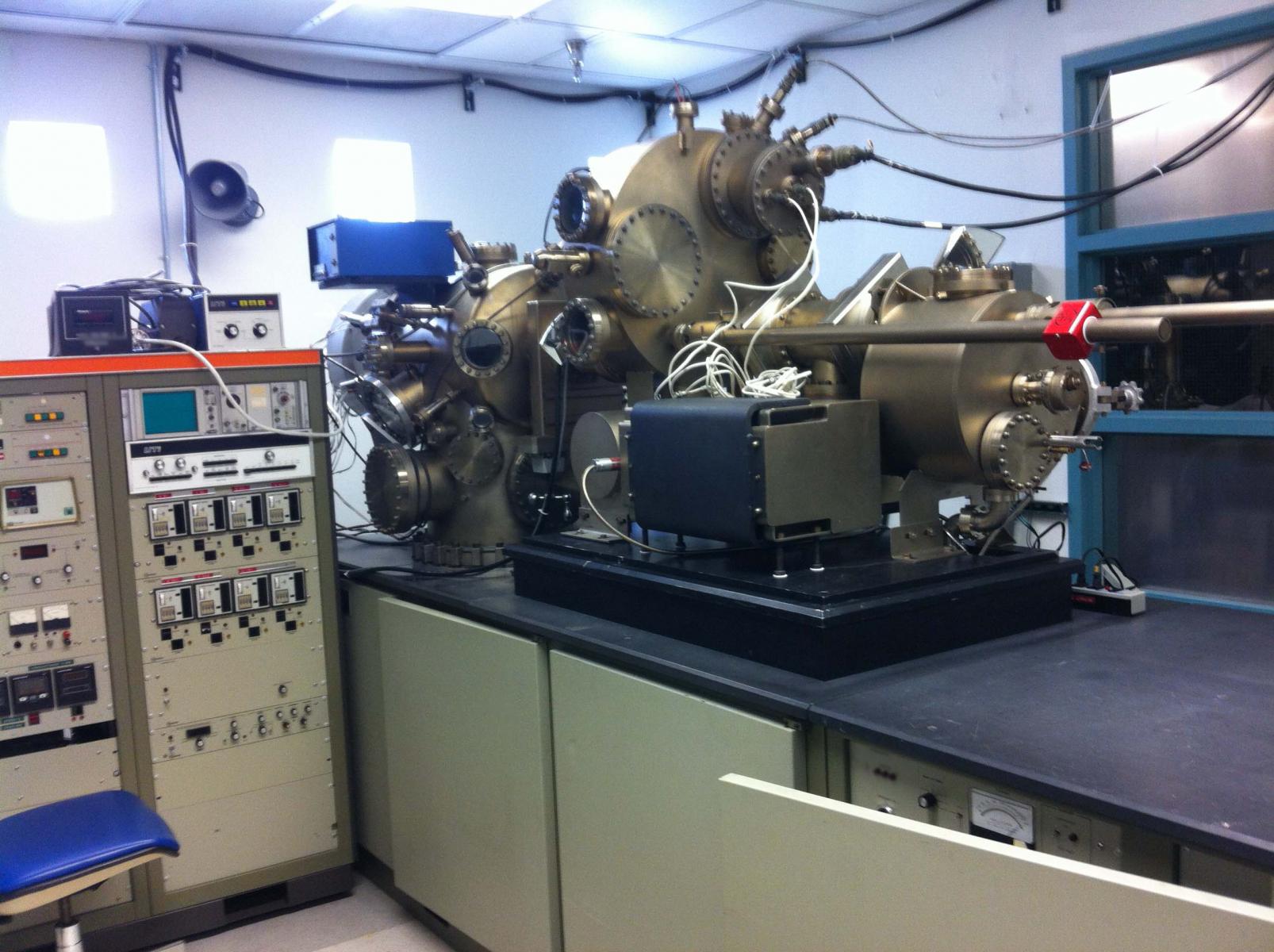

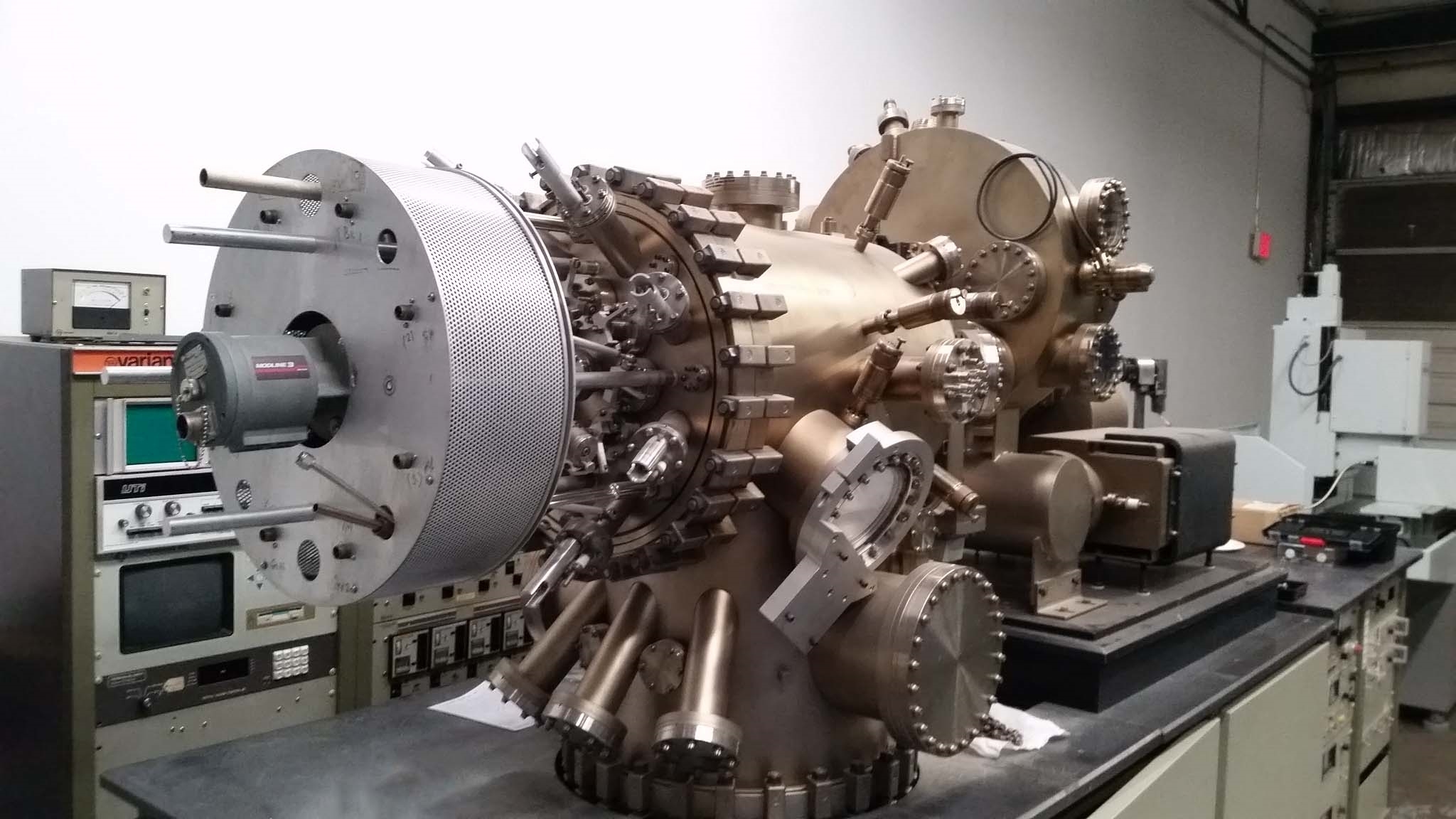

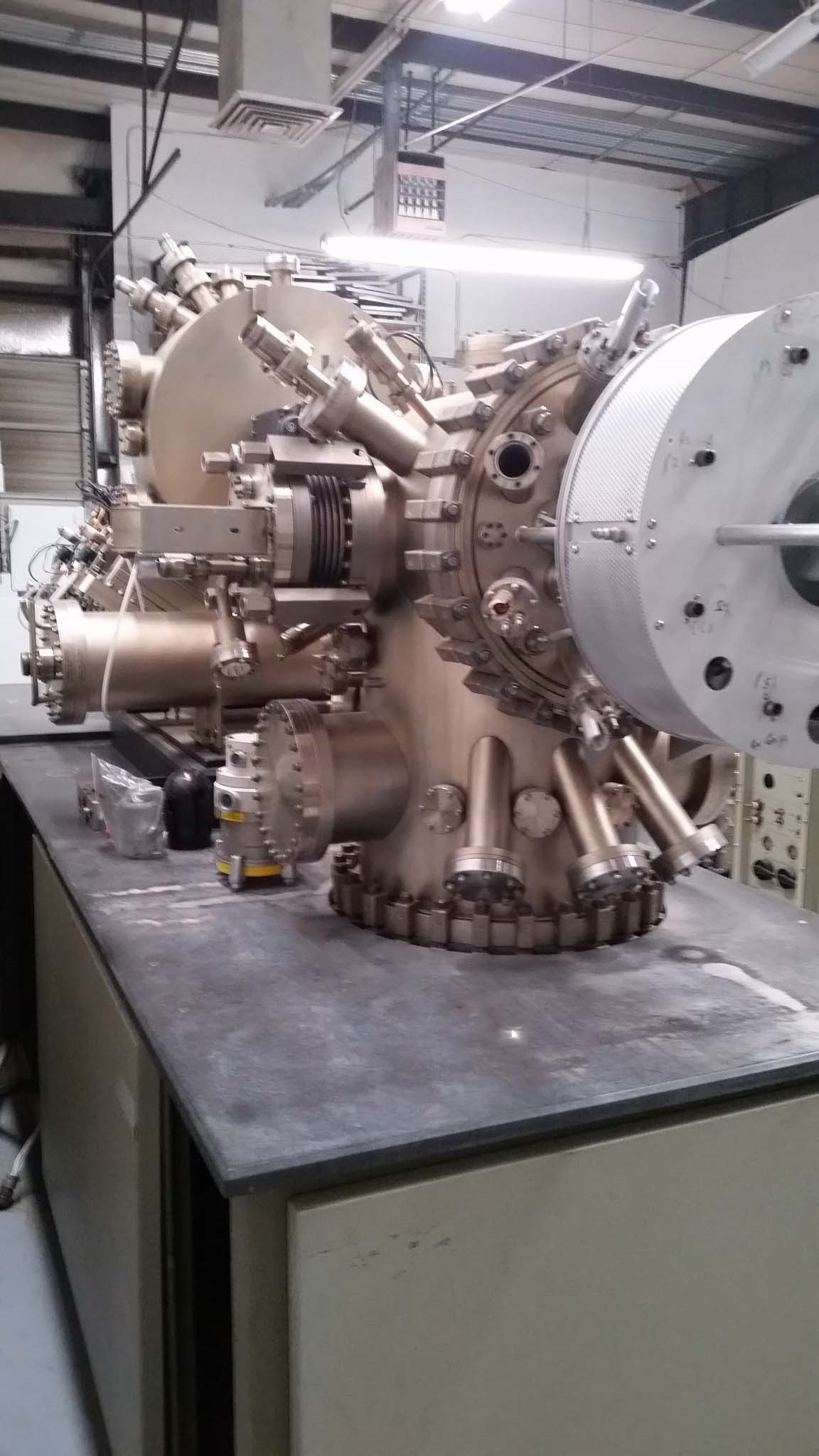

Used VEECO Gen II #9107591 for sale

URL successfully copied!

Tap to zoom

ID: 9107591

MBE System

Chamber with (8) source flange size, 2.75”

MBE Components:

RHEED System

Sample manipulator with flux monitor

QMS Head

Glove box

Pumps:

Cryo pump

Lon pump

Turbo pump

(2) Ion pumps:

Main chamber (600 l/m)

Buffer chamber (150 l/m) with (2) power supplies

(2) Ti-Sublimation pumps

With power supplies in the base of the main chamber

Manipulator, 2"

With servo motors for rotation

Position setting

Control unit

Heater power supply

Thermo-couple controller

Beam flux

Monitor and controller

(2) Ion gauges:

With (2) power supplies and controllers

Main chamber

Load lock

Load lock for 6 wafers

With heater for pre bake out with its power supply

Temperature controller

Electrical distribution panel

Bake out panels with electrical connections

Eight shutters with their control units

Utility distribution box for water, air, N2

QMS, Power supply & display unit

Operating system and computer

(6) Sample holders

Baffles head for main chamber turbo pump

Gaskets silver coated copper gaskets

Mixing manifold

With (2) leak valves and tubing for gas interceptor

Sulfur automatic valved cracker with:

(2) Temperature zones

100 CC Quartz crucible

(2) Power supplies

(2) Temperature controllers

Servo motor and controller and cable

Oxygen plasma source with:

RF Power supply

Matching unit

Leak valve

Water flow meter and filter

High temperature effusion cell with:

Temperature zone up to: 2000°C

10 CC Crucible

Power supply & temperature controller

Low temperature effusion cell with:

(2) Temperature zones (Base and tip)

25 CC PBN Crucible

(2) Power supplies

(2) Temperature controllers

Gas injector with:

Single heater

Power supply

Temperature controller and display

Mixed manifold with two leak valves and tubing

Options:

QCM Integrated

With machine for film thickness monitor

RHEED System

With 6" phosphorous screen and detector and camera

E-beam gun with power supply and control unit.

VARIAN / VEECO GEN II Molecular Beam Epitaxy (MBE) equipment is a highly advanced, multi-user deposition system for doping and deposition of a wide variety of semiconductor materials. This state-of-the-art MBE unit allows for precise control of the deposition environment for achieving high quality layers with excellent reproducibility. This machine allows for the deposition of high quality and uniform layers of semiconductor materials such as gallium arsenide and indium gallium arsenide. The deposition process is carried out in a vacuum chamber, where the substrate to be deposited is placed on a heated holder. Three types of effusive cells, manufactured by Caesars are used with the tool; an arsenic, a gallium and an indium cell. The combination of these three cells gives the user the flexibility to create complex and specialized thin film structures. The base pressure of the MBE asset is maintained at 4-6 x 10-7 mbar, and a separate load-lock model is employed to further reduce the pressure before insertion into the vacuum chamber. Additionally, the equipment contains a thermal oxidation unit, an ozone generator and two nitrogen lines in order to assist with surface preparation and growth enhancement. The substrate holder is heated electrically and is temperature controlled with a series of thermocouples, allowing for uniform temperatures on all areas of the sample, thus providing precision control for thin film deposition. The pre-set temperatures range from 200 K to 1,000 K. Moreover, VEECO GEN II equipment comes equipped with a state-of-the-art software package, which offers a variety of useful features for controlling the source emission and deposition process. The software includes a comprehensive set of tools for simulating growth processes, defining layer structures and performing various parameter calculations. Using powerful parametric optimization capabilities, users can also develop detailed simulations of their thin film structures, enabling them to maximize the performance of their samples. It also allows users to create graphical user interfaces in order to provide them with a convenient way to set up and monitor experiments. VARIAN GEN II MBE system has been designed to suit a wide range of scientific and industrial requirements, enabling users to take their research applications to the next level. This advanced unit is capable of producing high quality results and offers the flexibility to allocate different materials, atom by atom, in order to create complex thin film structures.

There are no reviews yet