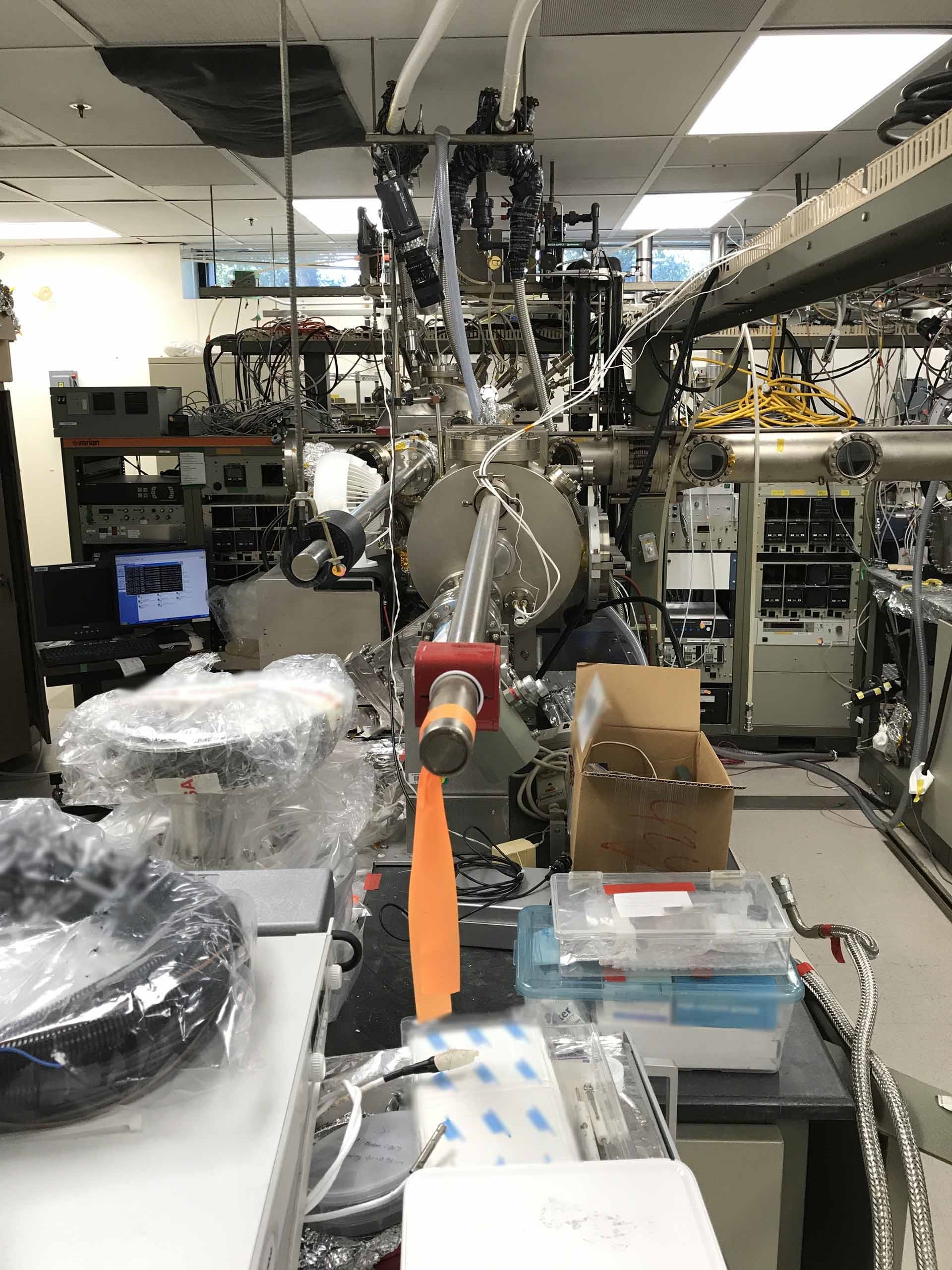

Used VARIAN / VEECO GEN II #9190525 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9190525

MBE Growth system

Combination of IV: Si / Ge / Sn

Ports, 2.75"

Chamber 1 (III-V):

Arsenic valved cracker

Indium effusion cell

Gallium effusion cell

Aluminum effusion cell

Ga downward looking source

Silicon effusion cell (5 cc)

Beryllium effusion cell (5 cc)

Chamber 2 (Group IV):

Germanium effusion cell

Silicon e-beam source

Silicon high temperature source

Tin effusion cell

Arsenic valved cracker

Boron dopant source.

Molecular Beam Epitaxy (MBE) is a technique used to create reliable, high-quality thin film structures. VARIAN / VEECO GEN II MBE equipment is a state-of-the-art tool for the fabrication of compound semiconductor devices and structures, such as multi-junction solar cells, quantum cascade lasers, and semiconductor components for optoelectronic and microelectronic applications. This system relies on a vacuum chamber to isolate the substrate from the gas molecules while they are being brought together. The substrate is placed on an electronically-heated resistive element known as a "cell" - which is typically made from quartz or aluminum nitride. Then, source materials are loaded into particle beam sources, where they are specifically heated to temperatures above the melting point of that material. For instance, a gallium source would require a higher temperature than an aluminum source. To accurately move particles, VEECO GEN II MBE unit uses a powerful, closed-loop photomicrocontroller-based beam-scanning machine. This tool monitors the amount, intensity, and spread of the particle beam from the source material, and then accurately adjusts the beam-scanning pattern in order to ensure an even deposition onto the substrate. The deposition process is further enhanced by the use of high-precision gas injection nozzles, giving the asset the capability to deposit multiple layers of different materials without any overlap. VARIAN GEN II MBE model also features an advanced programming interface, allowing the user to design their own deposition processes, adjust flow rates, and control the equipment remotely. Finally, the system includes an advanced temperature control unit, with the ability to maintain temperatures between 10°C and 1000°C with high accuracy and stability, allowing the user to accurately control the thin film properties and achieve a uniform structure. This makes GEN II MBE machine an ideal device for the fabrication of advanced thin-film structures.

There are no reviews yet