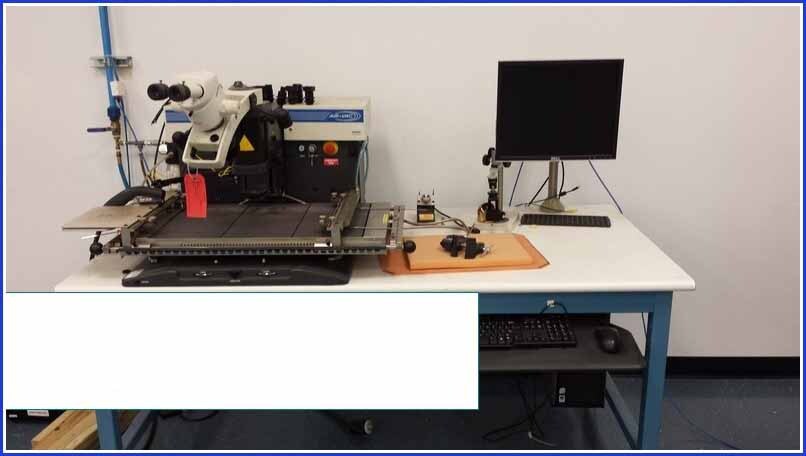

Used AIRVAC / ZEVAC DRS 25 #9179115 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9179115

Rework station

(3) Zones

24" x 16"

IR Preheater

Board size: 24" x 24"

Clearance (Top / Bottom): 1" / 1"

Power: 7500 W.

AIRVAC / ZEVAC DRS 25 is a pc board assembly and manufacturing equipment capable of complex and critical soldering operations. This system is composed of a tabletop production unit developed to meet the needs of production amount, quality, and consistency. It is equipped with high reliability components, such as its 8 nozzle heads, that increase the repeatability while also providing flexibility. The onboard touch screen panel makes setting up and programming the various soldering tasks fast and intuitive. ZEVAC DRS 25 is designed for large scale production operations, which can be achieved with its high speed and efficient temperature control. This ensures a consistent quality on all solders, regardless of the size and type of components being processed. It also provides a N2 or PAP compressed air input that can be used for air flow control and on demand product cleaning. The active nozzle heads of AIRVAC DRS 25 are made from stainless steel and are equipped with multiple sensors. The sensors enable the unit to accurately control the soldering temperature for each nozzle head and to shut off the machine if a component is beyond pre-set limits. This ensures that each connection is soldered perfectly in accordance with the manufacturer's specifications. The nozzle heads are designed with adjustable heights and angles, enabling them to work on various components and different heights. The AKI 250B8 1.2mm pneumatic soldering iron is designed for precision soldering operations. DRS 25 is built with programmable logic, allowing operators to easily program any soldering task, even complex ones involving multi-component assembly. It also comes with an advanced diagnostics tool which monitors the operating parameters, while at the same time detecting any anomalies in the asset. This helps to ensure that the model is always operating optimally and without any errors. To facilitate repairs and maintenance operations, AIRVAC / ZEVAC DRS 25 is equipped with a built-in fault-finding equipment and self-test. Some of the standard features of the system include manual operation, automatic recognition and tracking of components, and multiple power supplies for the electronic components. Additionally, the unit can be connected to a personal computer to facilitate data input, output, and remote monitoring. ZEVAC DRS 25 is an advanced pc board assembly and manufacturing machine that is ideal for large scale production operations. Its reliability, advanced features, and intuitive programming make it an excellent choice for those who require a consistent and quality soldering process. With its advanced diagnostic tool and fault-finding asset, AIRVAC DRS 25 greatly increases productivity while ensuring product quality.

There are no reviews yet