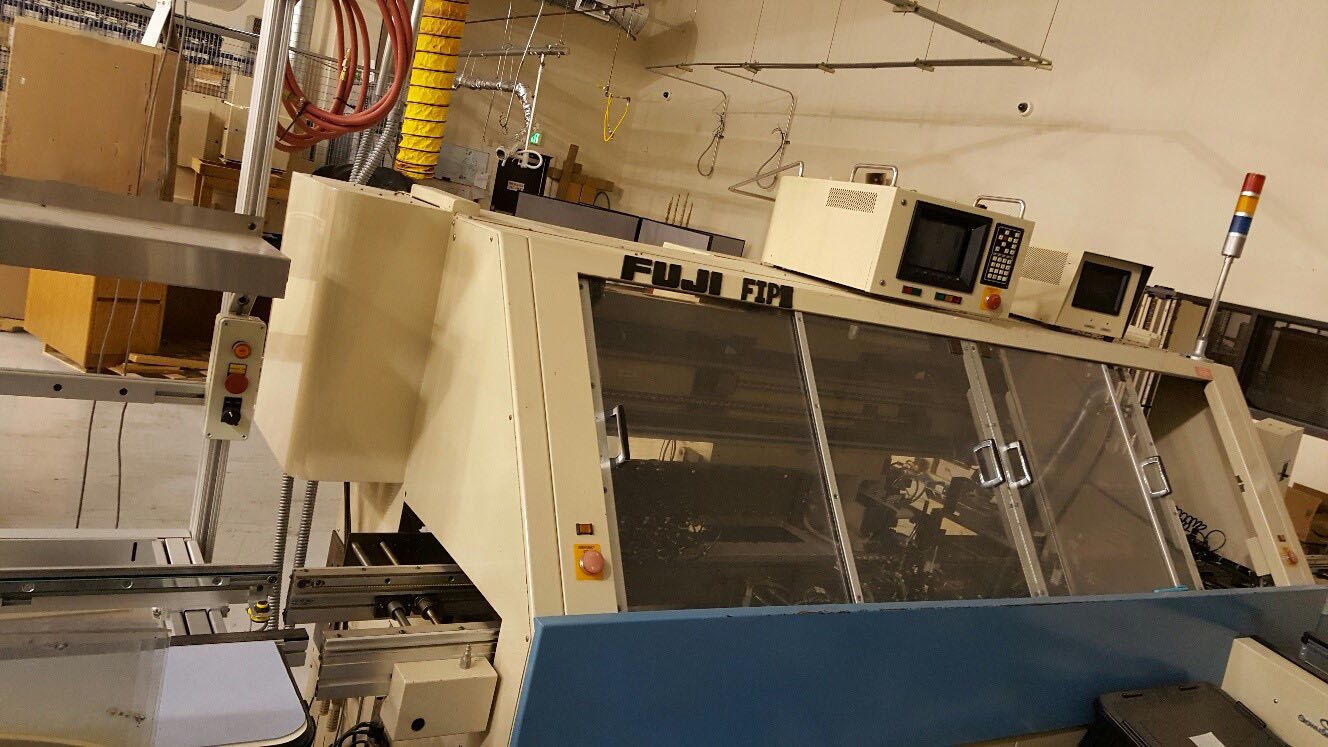

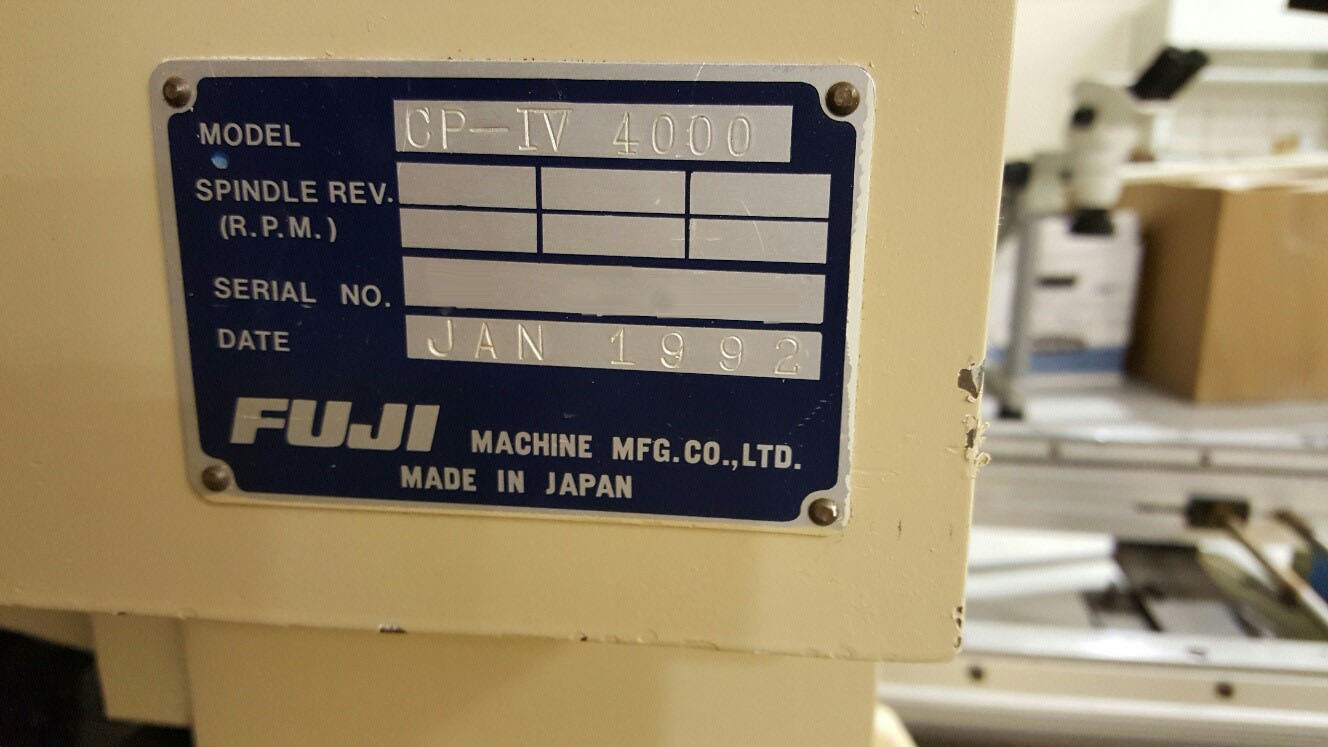

Used FUJI CP IV-4000 #9038710 for sale

URL successfully copied!

Tap to zoom

FUJI CP IV-4000 is a powerful PC board assembly and manufacturing equipment, designed for high-precision automated assembly and production. It is a highly efficient and reliable solution for achieving fast and accurate completion of PC boards, with minimal effort. The system is highly productive, with the ability to produce up to 850 boards an hour with no firmware required. Its multi-function operation includes panel-to-panel and board-to-board assembly, as well as auto-select options. CP IV-4000 also features an excellent user interface and intuitive control software. The unit allows for simultaneous operation of multiple programs, meaning that boards can be integrated into systems more quickly. There is also a vision machine which can detect components at an accuracy of up to 0.1mm and identify components with a resolution of up to 25 microns. FUJI CP IV-4000 offers a low failure rate due to its 'flaw detection' capability. This feature checks for defects such as shorts, missing components and incorrect parts before production. Other features include auto-optimized placement, high-speed pneumatic component insertion capabilities and auto-stop functions which detect and shut down any faults during production. CP IV-4000 also provides a range of user-friendly options such as touch panel interfaces, on-board and data logging. These features are designed to facilitate efficient operation with minimal downtime and effort. Overall, FUJI CP IV-4000 offers a wealth of features and benefits, ensuring optimum efficiency and accuracy with minimal effort and cost. Its versatile architecture, reliability, and user-friendly design make it an invaluable component in any PC board assembly and manufacturing setup.

There are no reviews yet