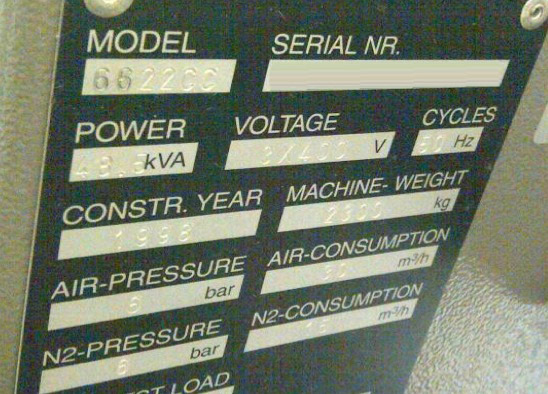

Used VITRONICS SOLTEC 6622 CC Delta Wave #9058750 for sale

URL successfully copied!

Tap to zoom

ID: 9058750

Vintage: 1998

Soldering machine

Leaded

Spray fluxer

Preheaters, bottom: Zone 1 and 2 - resistors calrod, Zone 3 - radiant quartz

Main, Smart and Chip Wave options: yes

Center board support: no; pallets used

1998 vintage.

VITRONICS SOLTEC 6622 CC Delta Wave is an advanced and reliable PCB solder machine designed to improve soldering performance and production throughput. It features a dual-wave capability that allows simultaneous soldering of both SMD and THT (through-hole technology) components and a wide, fully adjustable temperature range for maximum flexibility. It also features a comprehensive tool and motion control package to ensure precise, uniform soldering of any board size. The machine's wave technology aligns the two heated elements, the main wave and the high-temperature secondary wave, to provide maximum thermal conduction and precise heat transfer to the component being soldered. Through precise control of the timing and temperature of the main wave and secondary wave, consistent solder joint formation can be obtained for even large or complex components. This eliminates over-heating of smaller components, which can damage or disfigure them, providing a much higher quality of soldering. VITRONICS SOLTEC 6622CC DELTA WAVE's motion control system is designed to provide precise and uniform movement of the element and the component being soldered. It uses a flexible robot arm configuration with multiple, individually adjustable fixed points to precisely control the vertical and lateral motion of the element and orientation of the component. This allows it to precisely locate, position and solder each component, while its intelligent software minimizes the time it takes to complete each cycle. The machine's wide and adjustable temperature range provides a high degree of intuition, allowing for fast process cycle adjustments from a wide variety of component types and sizes. 6622 CC Delta Wave also features an efficient, built-in temperature control unit and self-calibrating convection technology for superior heat transfer. Furthermore, VITRONICS SOLTEC advanced process control interface helps streamline setup times, while its data logging capabilities allow for comprehensive, real-time analysis and tracking of all manufacturing processes. Its accelerated reflow process improves reflow oven performance, while its on-board mis-soldering detection functions detect incomplete solder joints, allowing the machine to quickly modify welding parameters for improved accuracy and reliability. 6622CC DELTA WAVE is constructed using high-grade stainless steel and is thoroughly tested and inspected to ensure its long-term performance and reliability. It is designed to meet the most stringent safety standards, and its intuitive user interface makes it suitable for use by operators of all levels of experience.

There are no reviews yet