Used TEL / TOKYO ELECTRON Mark 7 #118737 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 118737

Wafer Size: 8"

Vintage: 2010

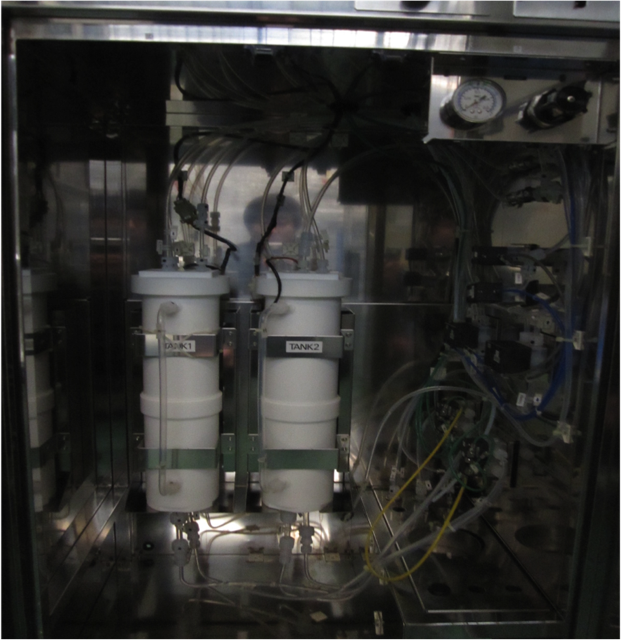

Track system, 8"

Left to right orientation

4 cassette stage, 2 spin

Main controller:

NEC FC-9801BX computer

C/S robot type:

Ceramic pincette

Main robot type:

2 Finger wafer transfer main robot

Indexer:

4 cassette carrier station

25 wafer slots cassette

Spin:

Stream nozzle thinner dispense

Stream nozzle top rinse dispense

Spin servo motor

Digital vacuum sensors and interlocked for spin unit

2010 vintage

As-is, where-is.

TEL / TOKYO ELECTRON Mark 7 Photoresist Equipment is a comprehensive photoresist coating and development solution for advanced applications in the semiconductor industry. The system consists of four distinct components, each of which works together to provide top-notch process control, accuracy and precision. TEL MARK7 Photoresist Coating Module is the first component of the unit. It enables precise, repeatable and uniform coating of thin resist films, thanks to its two independent coating heads and powerful pumping machine. Its precise force-feed dispersing roller ensures an enhanced coating performance and allows coating with high molecular weight resists. TEL PMS-003 Intelligent Dispensing Unit further optimizes the performance of the marking 7 coating module. The second component of the tool is TOKYO ELECTRON Pattern Generating Module. This module makes use of a state-of-the-art direct-write beam-steering mechanism, making it possible to generate a wide range of pattern shapes and sizes. The module also has the added convenience of allowing data transfer from one resist asset to another, allowing users to easily recreate complex patterns across multiple projects. The third and fourth components of TOKYO ELECTRON MARK-7 model combine to offer automated resist development. TOKYO ELECTRON MARK7 Resist Development/Inspection Unit provides live-time imaging of resist patterns as they are formed and scanned by an integrated visual inspection module. The inspection module can be used to automatically detect resist pattern defects, enabling immediate corrective action. Additionally, the Resist Development/Inspection Unit is equipped with an ultrasonic-based cleaning equipment, boosting the accuracy and clarity of resist pattern completion. Overall, TEL / TOKYO ELECTRON MARK7 Photoresist System is a powerful tool for superior process control, accuracy and precision. Its four components work together to provide unparalleled photoresist coating and development solutions, enabling advanced semiconductor applications.

There are no reviews yet