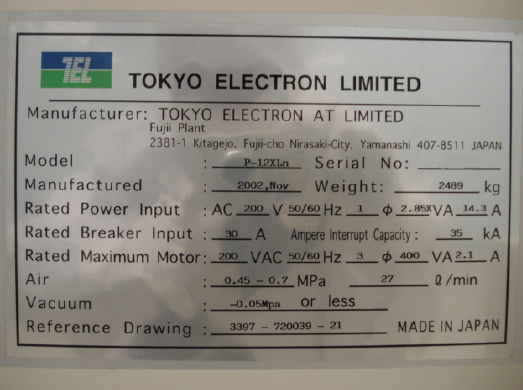

Used TEL / TOKYO ELECTRON P-12XLn #126967 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 126967

Vintage: 2002

Wafer prober, 12"

Fail mark inspection: Yes

Needle inspection option: Yes

Auto needle alignment option: Yes

Auto needle height setting: Yes

Off site marking: No

Auto card changer: Only card PGV

Camera Oblique and coaxial: Yes

TH Clamp: Yes

Card guide drawer: No

High rigidity chuck: Yes

RS232: No

GPIB: Yes

Driver marker by category: No

Cleaning unit: Z-WAPP

Z-Axis stroke long: Yes

Hot/cold chuck temperature: +50 to +150°

Internal printer: No

External printer: Yes

OCR: No

Dual cassette: No

Single cassette: Yes

SACC Cart available: Yes

Alignment board (VIP1, VIP2, VIP3, etc): VIP3

Linear scale: No

Chiller: No

Stored in a warehouse

2002 vintage.

TEL / TOKYO ELECTRON P-12XLn is a prober designed to launch precise, automated measurements and inspections. This prober is aimed at providing semiconductor users with higher throughput and improved operational efficiency, whether working on single wafer or 4-inch wafer. It is a highly suitable choice for a wide range of applications such as probing and contactor testing, micro-bump, RF testing and probing, flip-chip bump bonding, precision positioning, and many others. The prober boasts a compact body, with a maximum size of 1,540 (W) x 1,760 (D) x 1,660 (H) mm, meaning it can be placed in almost any environment. TEL/TOKYO TEL P 12 XLN equipment is capable of a broad range of tests that includes contact checking, verification, IR drop, and Dommon Area Bridging. Additionally, it offers throughput and system performance excellent for its class. The tool offers a prober construction with an excellent range of motion and accuracy. The table area is among the largest in the industry, allowing for up to 54.2 mm x 54.2 mm of traverse and 55 mm stroke. Moreover, the unit features a built-in dynamic fine feeder and linear servo motor, which contribute to creating high-precision movements and exceptional alignment accuracy. This prober also features a high-speed mounting and dismounting of wafers with a newly developed wafer changer, increasing throughput significantly. It is capable of taking measurements at 25µm accuracy and beyond. Furthermore, TOKYO ELECTRON P-12 XLN offers excellent protection of the wafers during the process via a secure seal construction with a dust-proof design to guarantee cleanliness. The machine also has an advanced software package, which permits complete control with high accuracy. This includes built-in software for several test functions, fully computer-controlled operations, and macro programming. Moreover, users have access to online information about the product with detailed specs and manuals for use. Overall, P-12XLn is an excellent choice for automated measuring and inspection needs. It ensures superior accuracy, high throughput, flexible operations, and a secure environment for the wafers. Thanks to its features and capabilities, the prober is highly suitable for a wide range of applications and industries.

There are no reviews yet