Used LAM RESEARCH / NOVELLUS Vector Express #9099742 for sale

URL successfully copied!

Tap to zoom

ID: 9099742

Wafer Size: 12"

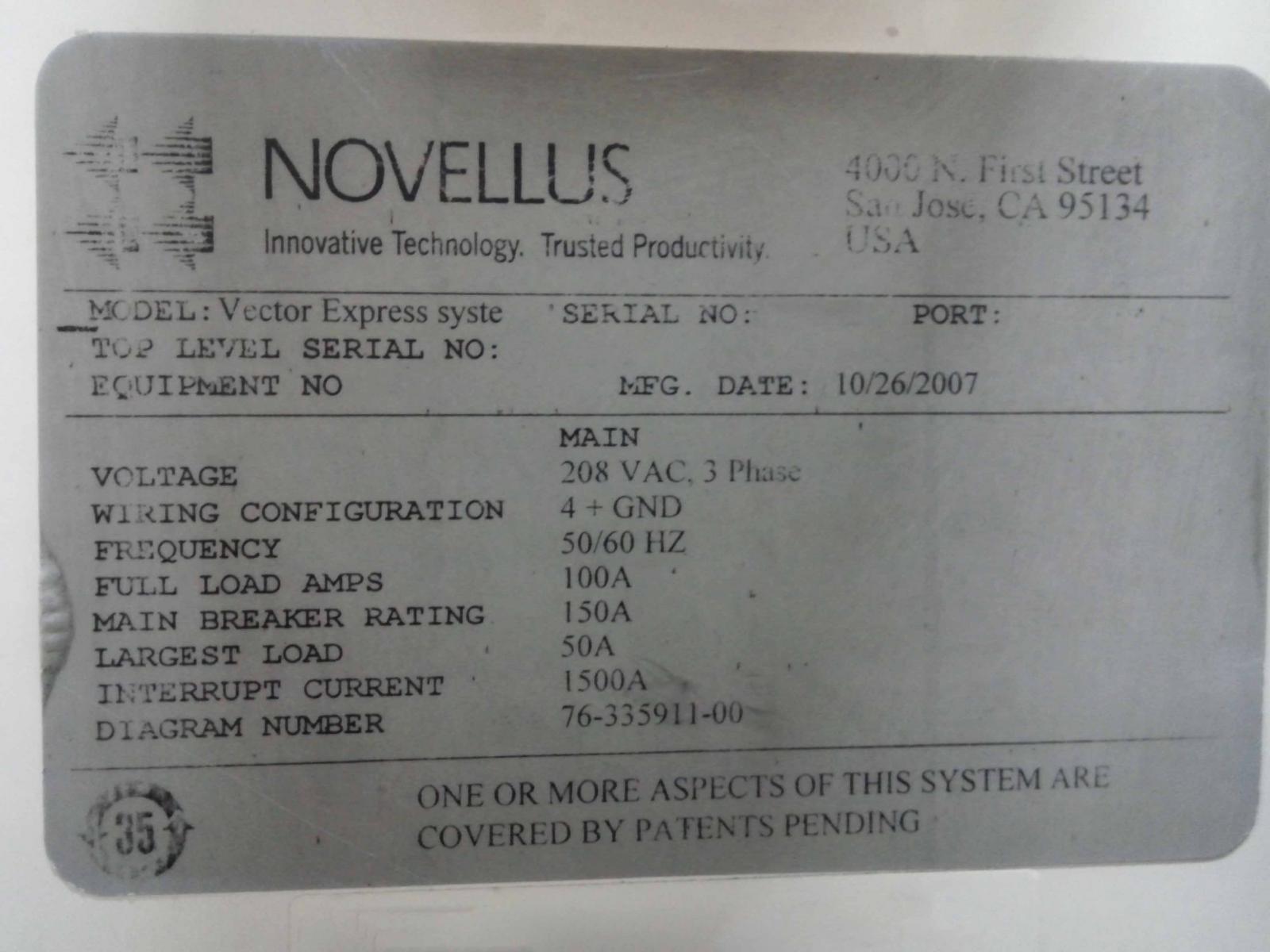

Vintage: 2007

CVD System, 12"

System configuration:

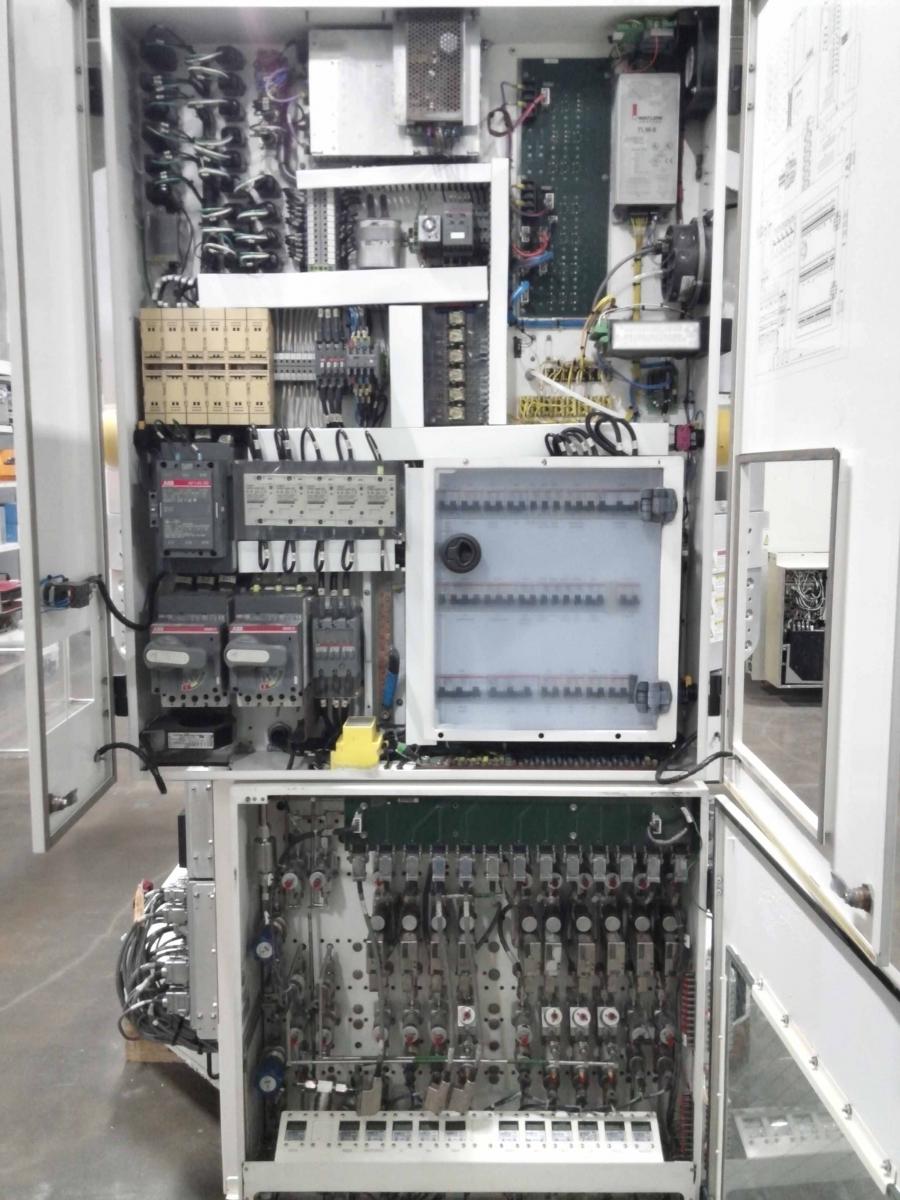

Front UI

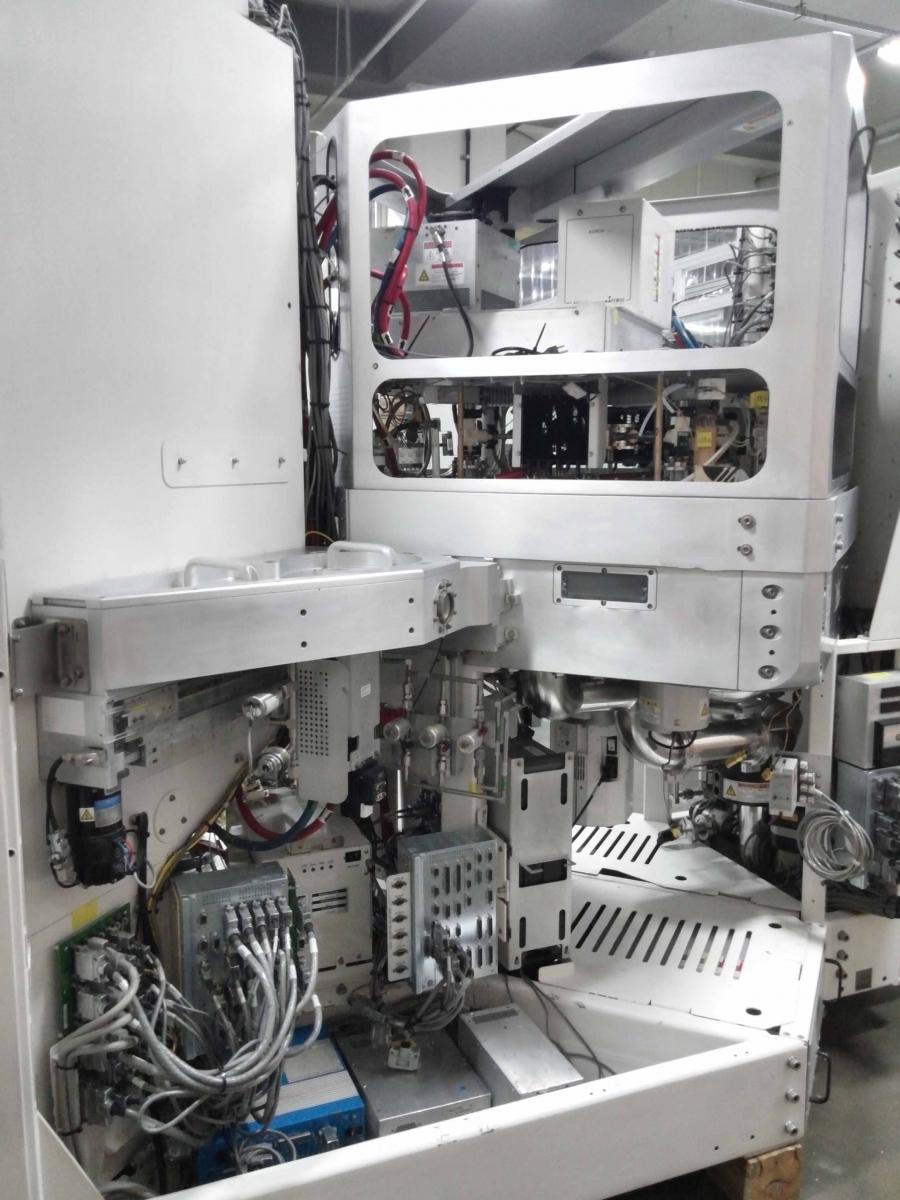

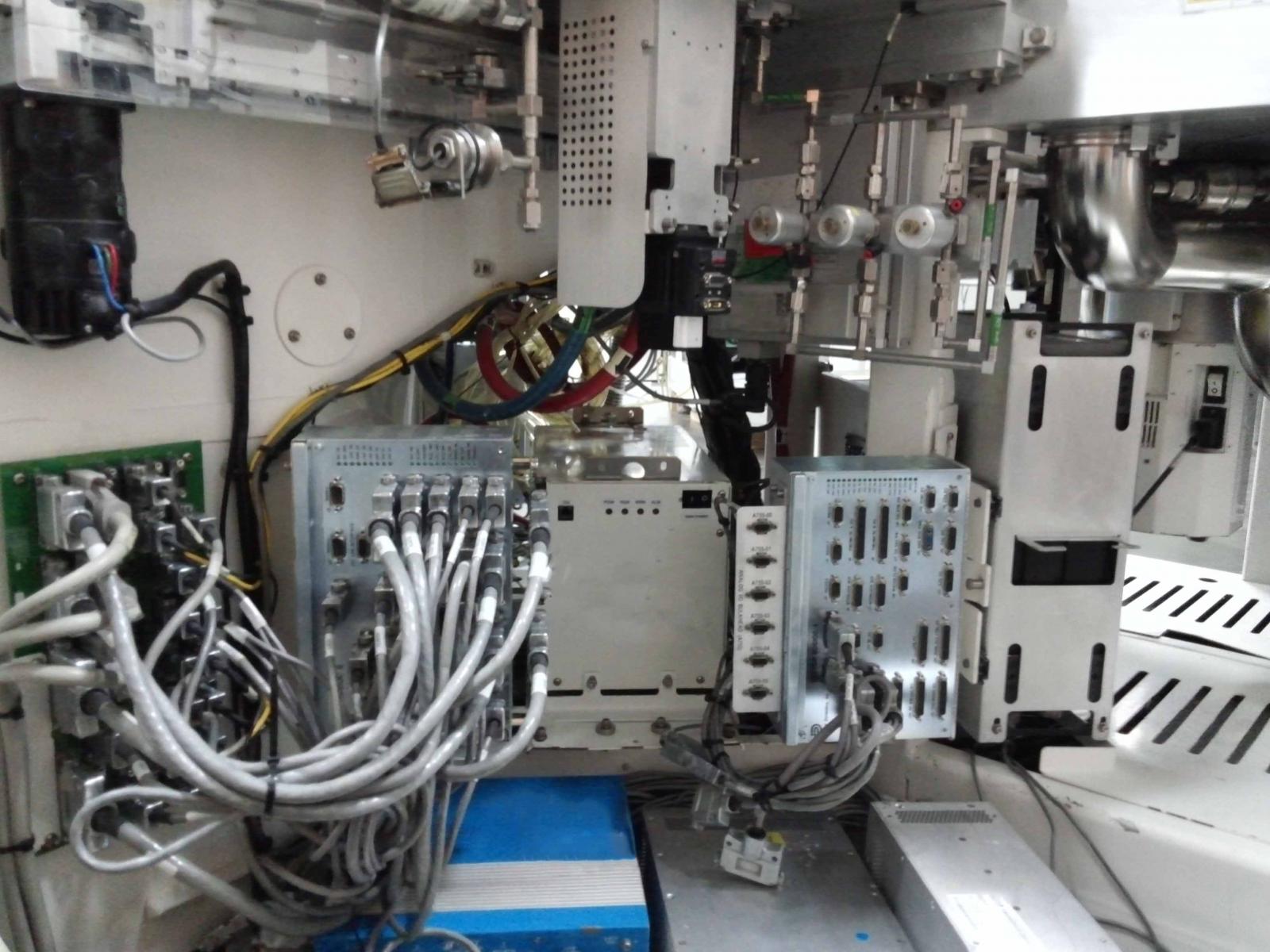

System controller: MC3E, 02-257935-00

Module controller: MC3E, 02-253704-00

IOC: IOC#0,1,2,3 HDSIOC

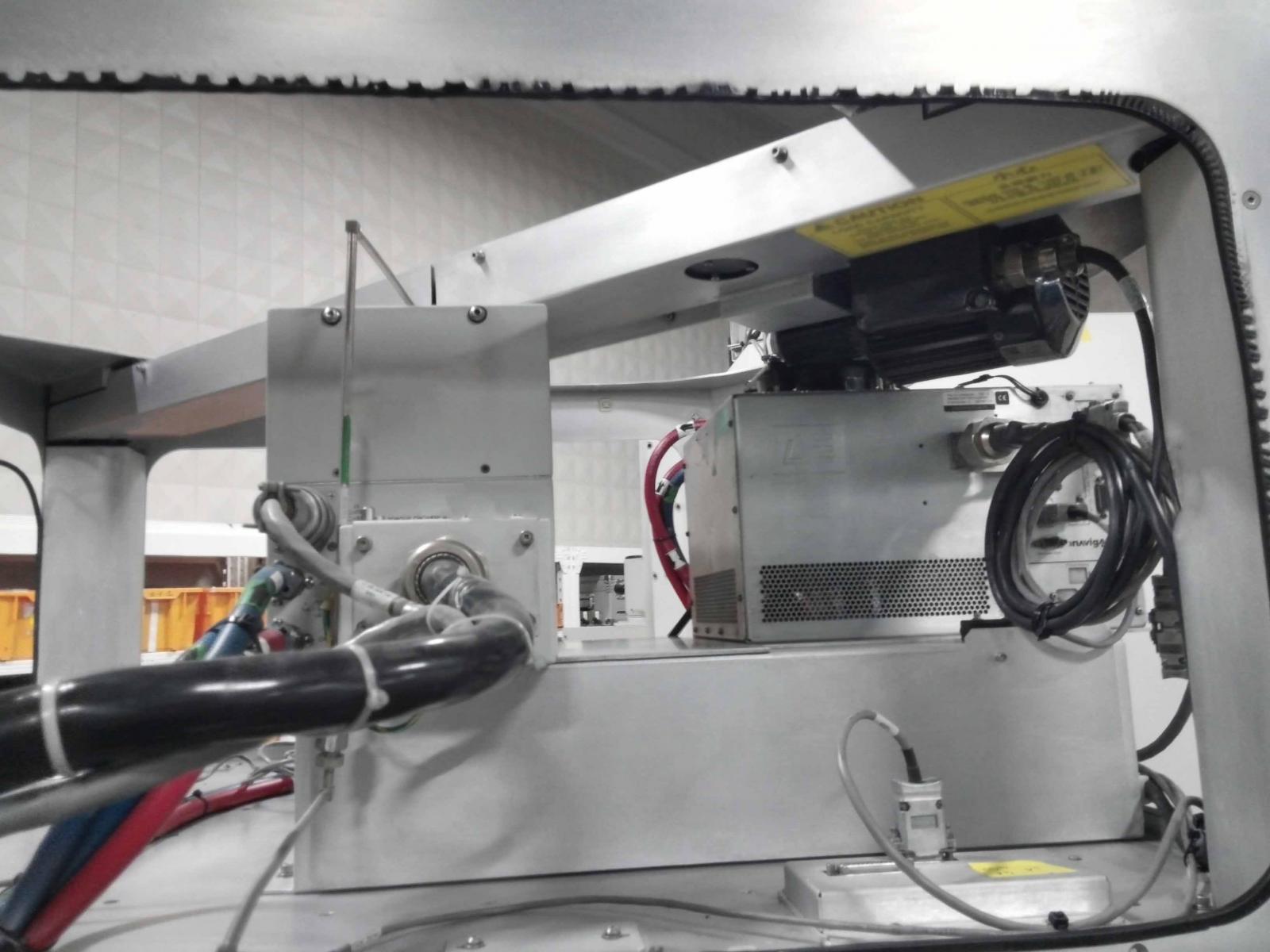

ATM Robot & controller:

BROOKS RELIANCE 8

Type: Friction

Controller 129974

Trust controller: C-2027-D01

ULPA Filter

(3) Pod loader: Fixload 6M

LL/FE Interface PCB: 03-283968-00

Loadlock configuration:

(2) ATM Door valves: VAT

(2) Chamber slit valves: SMC

L/L Manometer: 10 Torr 750B 11TCE2GK

Vacuum switch

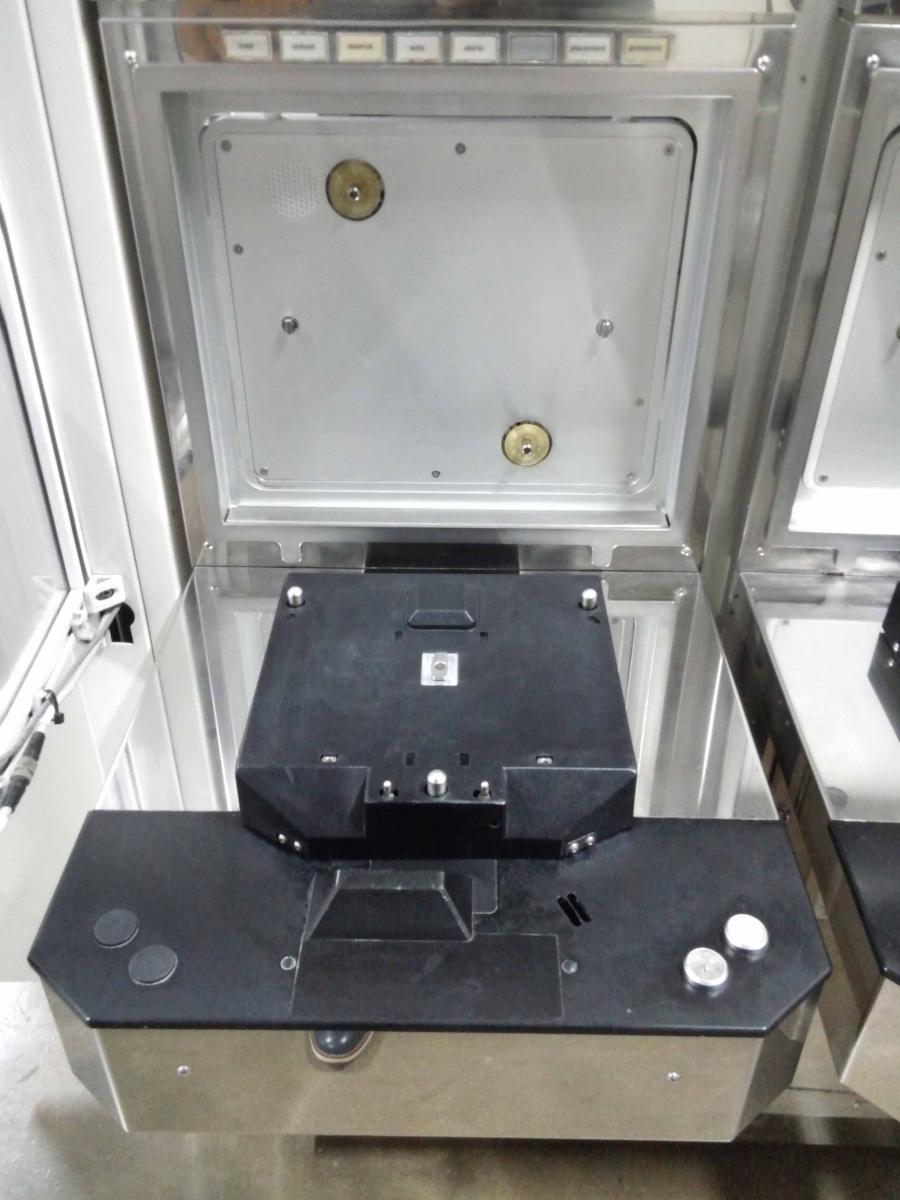

LTM type: LTM II

Preheat pedestal

Pedestal lift type: Servo motor (Both)

Vent / Purge valve

L/L On-board pump: KAWASAKI 27-283364-00 NV60N--2

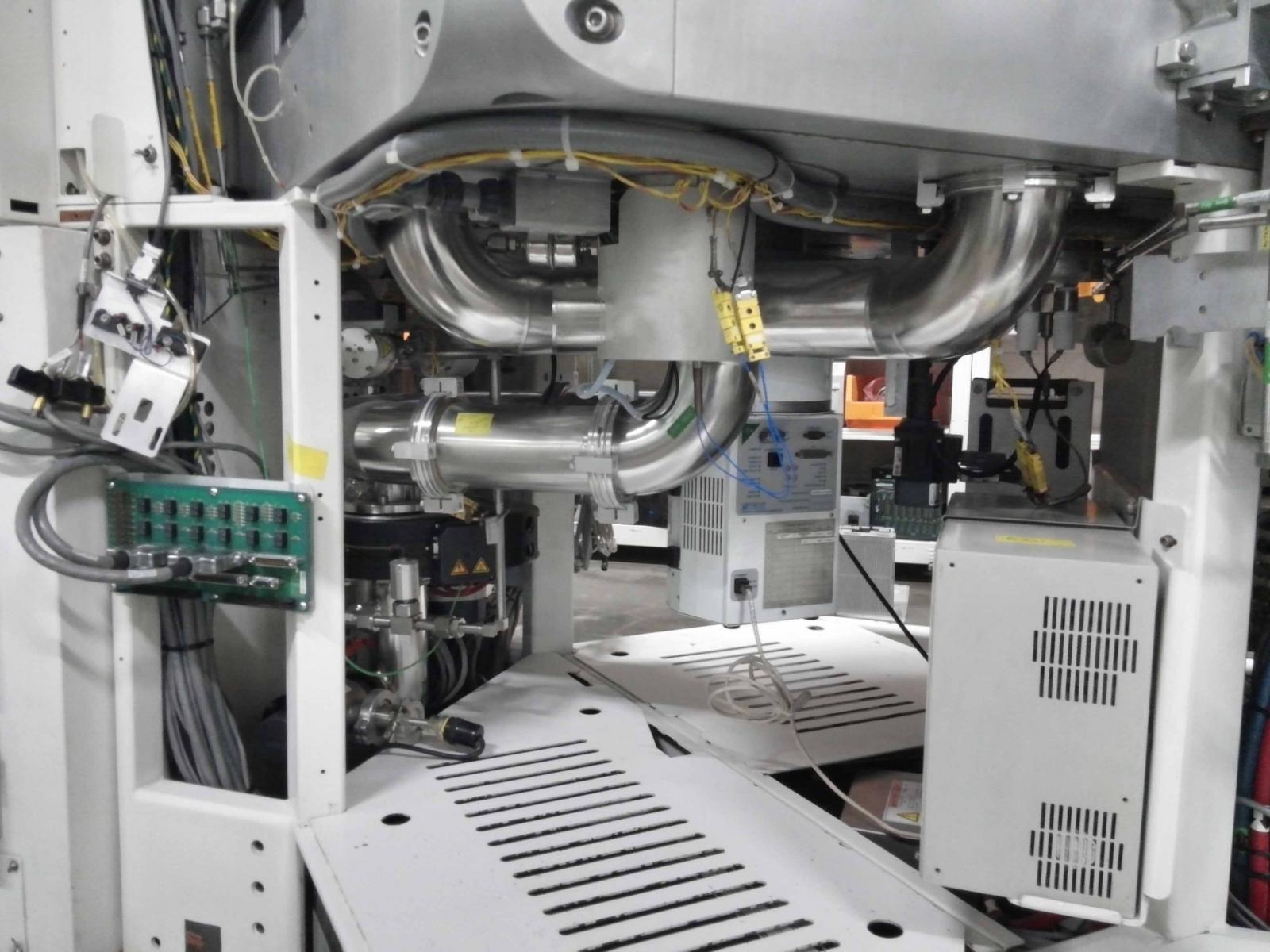

PM Configuration:

Module type: PSIN

HF Generator: Apex 3013

LF Generator: PDX2500

LF Fixed matcher: X

HF Auto matcher 27-279938-00

Navigator: 10013-L80MFI 3155162-002 D

RF Distribution type: Balance kit

RPC Source:

Large RPC / Astron hf-s / 27-282770-00

RPC Power supply: AX7645

Pendulum valve: VAT / PM7 Controller X

Pedestal: Standard type

Shower head

Endpoint detector: IREPD - MKS

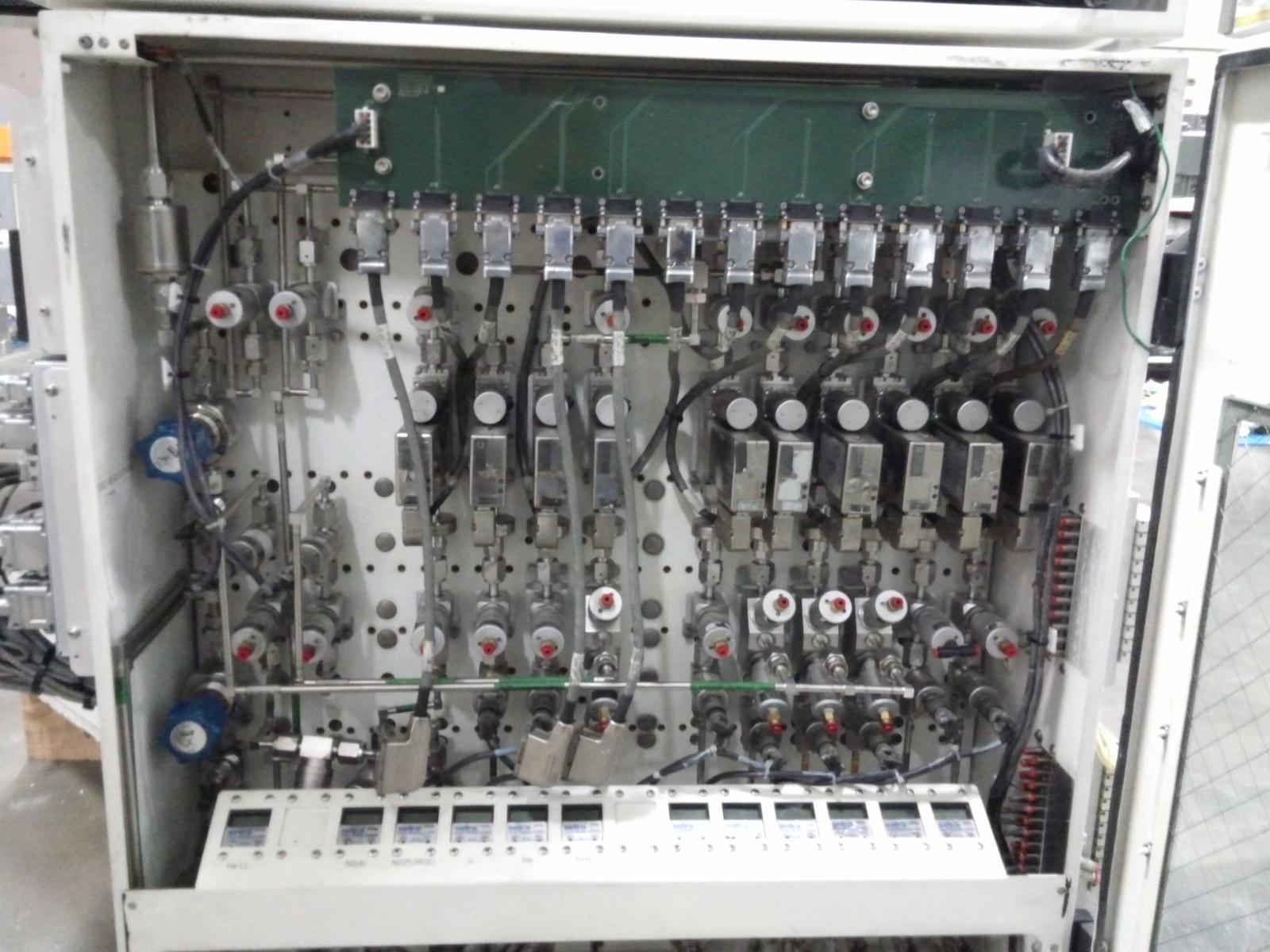

Gas box: 02-323496-00 / SRD 200107436

MFC:

BROOKS SLA7950S

MFC 2 N2 10000

MFC C Ar 10000

MFC 5 He 20000

MFC 1 SiH4 1500

MFC B N2 20000

MFC 6 NH3 20000

MFC 9 NF3 10000

MFC 8 O2 30000

MFC A N2O (L) 1500

MFC 7 N2O (H) 25000

Arm position detector

Gauge monitoring kit

Spindle type: Servo motor, 27-278697-00

Stn#1 pin lift type: Servo motor

Missing parts:

PM7 Controller

Gauge tree

Power: 208 VAC, 3 Phase

Main 150A

Full load 100A

2007 vintage.

LAM RESEARCH / NOVELLUS Vector Express is a high-performance etcher and asher tool used in microfabrication processes. It is a multi-chamber system with eight independent chambers capable of performing multiple process steps simultaneously. NOVELLUS Vector Express is a platform for etching dielectrics, metals, photoresists, low-k materials, along with gap filling and cleaning applications. The etcher has a high Plasma Source Power (PSP) of 1360W operating in parallel operation mode. This high power ensures successful enablement of high-speed etching processes which provide microfabrication needs by with high throughputs. Additionally, the high PSP is beneficial for etching of etching sensitive materials and hard to etch films. Moreover, LAM RESEARCH Vector Express is suitable for etching multi-layer stacks comprised of both traditional and advanced materials. Vector Express' flexibility is further enhanced through its efficient cooling system which allows its chambers to be operated within 0-110°C range. This ensures etching of nearly any material without damage or degradation of the substrate. LAM RESEARCH / NOVELLUS Vector Express' temperature-controlled roll and chuck provide uniform and precise pre-heating of the substrate to provide an even etch without pattern distortion. It has a fast wafer-climate shift of ±20°C within 5 seconds which can reduce defects and improve current yield. Moreover, its thermal control accuracy is also excellent with a stability rate of better than 0.1°C. This makes NOVELLUS Vector Express ideal for successful etching of delicate patterns and for increasing yield. LAM RESEARCH Vector Express also boasts a high degree of process control. Its process-based interface has been designed to let users control all etching parameters, such as plasma intensity, gas flow, RF frequency, pressure, and cooling mechanism. All these settings are readily available from the interface and can be monitored and adjusted to fine-tune the etching process easily. In conclusion, Vector Express is a premier etcher/asher tool which provides unsurpassed level of flexibility for etching various microfabrication materials. It is well-suited for etching high-aspect ratio features and for working on intricate micro-patterns due to its efficient temperature control and high PSP capabilities. Furthermore, its easy-to-use process-based interface facilitates easy control and monitoring of all etching parameters. All these features make LAM RESEARCH / NOVELLUS Vector Express a great choice for those looking to perform efficient, precise, and high-quality etching and ashing operations.

There are no reviews yet