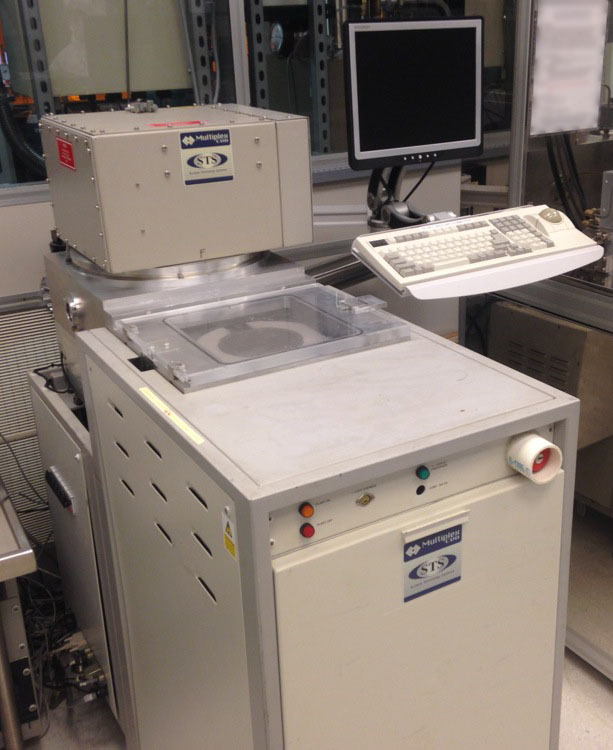

Used STS / CPX Multiplex #9071736 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9071736

Wafer Size: 3"-8"

PECVD System, 6"

Operating system: Window 98

Capable of 3"- 8"

Currently depositing: SiO2, Si3N4

Single chamber loadlock

Substrate size: Pieces up to 8"

AE Low RF & high RF generator

SMC Chiller for shower head

Single vane pump for loadlock

Pump / Blower package for chamber

Gas lines:

2%SiH4 in N2

N2O

NH3

N2

Cleaning gases:

O2

CF4

208 VAC, 60 Hz, 3P, 5W

~1997 vintage.

STS / CPX Multiplex is an etcher/asher equipment designed for the high-throughput processing of photomask substrates. It uses multiprobe etching/ashing technology to handle a wide variety of application requirements including High Aspect Ratio (HAR) etching/ashing, side etching/ashing, as well as other advanced process technologies. The system is designed for stability, consistency and high-throughput with the ability to process up to 200 samples in a single run. At the heart of the unit is a high-precision, dual-probe stage which operates within tight process-control parameters to ensure repeatable and reliable etching/ashing results. The dual-probe provides extremely fine accuracy allowing for a wide range of process parameter adjustment. The machine is also equipped with integrated scanning technology that allows users to quickly and accurately generate appropriate etching/ashing masks. This significantly helps improve the accuracy and speed of high-precision processes, reducing cycle times and increasing throughput. The advanced end-point detection capability of the tool ensures that critical process steps are accurately monitored, significantly reducing both over- and under-etching/ashing as well as the risk of contamination. STS Multiplex uses low-abrasion technology to process a wide range of materials, including single- and double-layer photomasks, and provide consistent etching/ashing results over multiple jobs. CPX Multiplex systems have full digital control, allowing precise and uniform etching/ashing on all applicable materials, and reducing operator-error risks. The systems are also equipped with robust end-point detection, allowing accurate product throughput and uniform results. The asset includes a range of optional hardware and software features, including high-resolution real-time temperature monitoring, real-time plotting of etching/ashing curves, and an integrated, user-friendly graphic interface. The model has a wide range of process parameters which can be adjusted for specific applications, and applied simultaneously, providing precise and reliable process control. Multiplex etcher/asher systems are compatible with the latest etching/ashing technologies and materials, and are integrated with the most advanced process control systems. Its robust, full-function design provides high-quality and reliable etching/ashing performance on a variety of materials, and its process stability ensures that critical processes are monitored and executed accurately. The equipment also provides maximum flexibility and versatility, allowing for compatibility with a variety of application requirements and etching/ashing materials. The system provides users with a high-throughput, highly reliable etching/ashing process that meets the needs of the most stringent applications.

There are no reviews yet