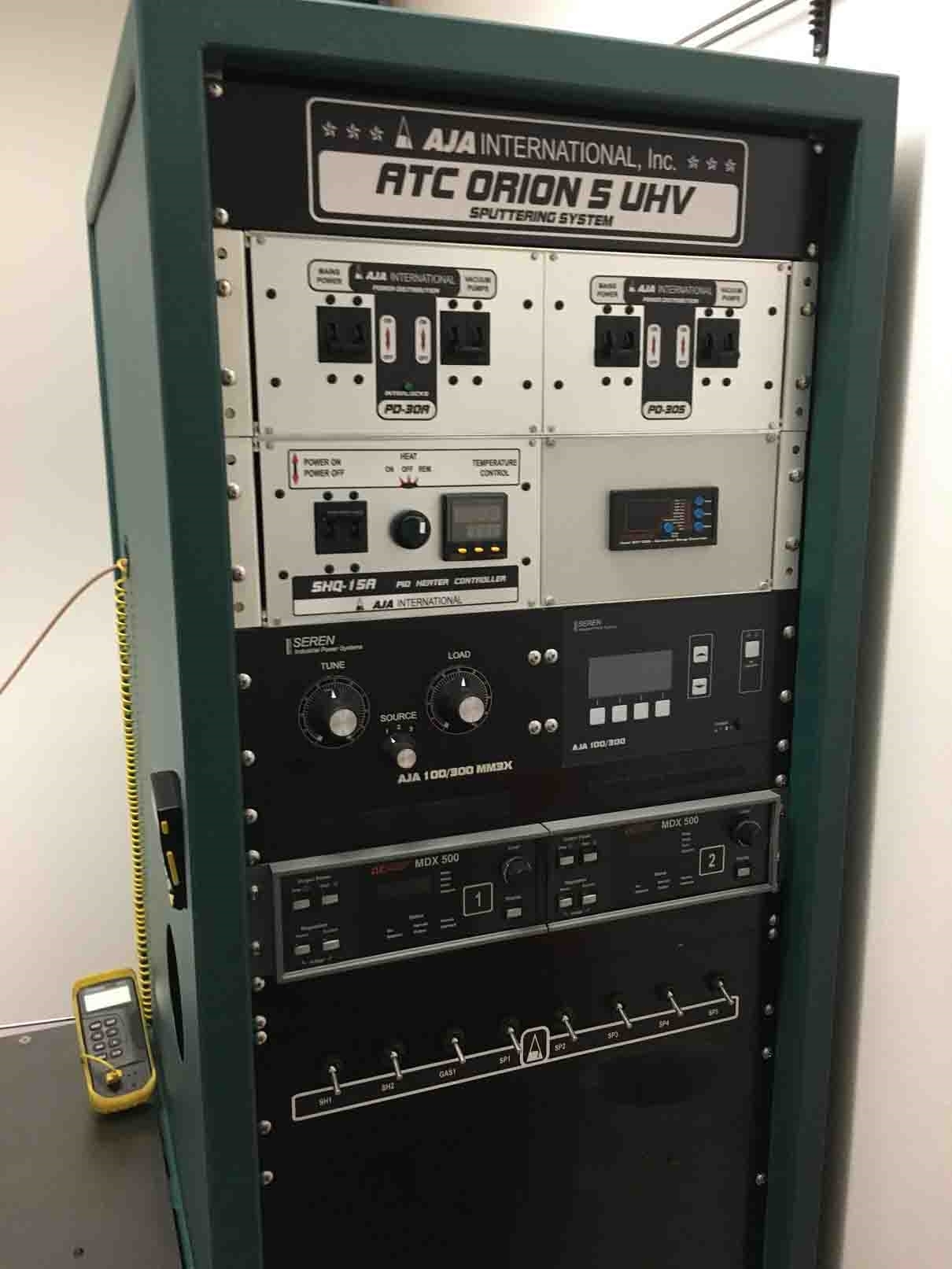

Used AJA ATC Orion 5 UHV #9049698 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9049698

Vintage: 2006

Sputter coater

Currently configured for manual operation, fully automatic capable

Substrate bias and rotation

(3) Independent sputter guns

(2) DC Power supplies, 500W

RF Power supply, 300W

Substrate size:

< 5.75" diameter (sputter-up) with z-axis shift (2")

Rotation to 20 rpm

Heating up to 800ºC with RF bias capability to 50 W RF

Sputter guns:

(3) 2" O.D. Targets

With integrated shutters for RF or DC (metallics/dielectrics) sputtering

Confocal, sputter-up arrangement

Capable of being upgraded to (5) cathodes

Power supplies:

(2) ADVANCED ENERGY 500 W DC supplies

1300 W Seren RF generator with manual impedance match and selector switch

Substrate heating:

PID Temperature programmable controller

(2) 1000 W Quartz lamps for heating inside water-cooled reflector box

Vacuum generation:

PFEIFFER 500 L/sec turbo pump

With magnetic bearing on vac side and ceramic bearing on motor side

Backed by ADIXEN ACP15 dry rotary lobe pump: Oil-free deposition system

Sputtered: metals and metal oxides:

Copper

Precious metals

Nickel

Iron

Vanadium

Molybdenum

Aluminum

Alumina

Carbon / Graphite

Currently de-installed and stored in a cleanroom

2006 vintage.

AJA ATC Orion 5 UHV is a sputtering equipment used in processing materials with a high level of accuracy and precision. This advanced system utilizes a powerful high-vacuum unit, capable of sustaining a maximum vacuum pressure of 6.5x10-7 Torr. It features a 5-target sputtering chamber, with 8-grounded heated anodes, allowing for different sputtering configurations, including high-power and low-power sputtering operations. The machine also includes a modular design, with an adjustable target-to-substrate distance, and an automated high rate plasma cleaning feature. In addition to sputtering advancements, ATC Orion 5 UHV tool features temperature control for substrates. This asset supports an active heating range up to 500°C, allowing for precise temperature control of the substrate surface. This feature provides greater control over film morphology and composition, as heat treatment can drastically influence the properties of metallized components. AJA ATC Orion 5 UHV offers precise motion control to enable accurate coating deposition without contaminating the target surface. The motion control allows for flexible programming, with linear and helical scan patterns, to ensure even film deposition rate. It also features an oscillation scan model, which precisely scans the target by oscillating the target in the X-Y plane to reduce the effects of target inter-diffusion. Finally, ATC Orion 5 UHV features an advanced automation equipment to ensure accuracy and repeatability within sputtering process parameters. This system includes computer-controlled operation, a multi-program sequencing capability, and user-friendly graphical programming tools for easy operation. It also tracks sputtering parameters and parameters to ensure repeatability and reproducibility of coating results. Overall, AJA ATC Orion 5 UHV is a powerful and highly precise sputtering unit, ideal for conducting thin film deposition processes. Its active heating range and precise motion control offer greater control over the deposition of materials. Its automated functions maximize efficiency, and reduce the time required for processing materials. With these features, ATC Orion 5 UHV is the perfect solution for many thin film applications.

There are no reviews yet