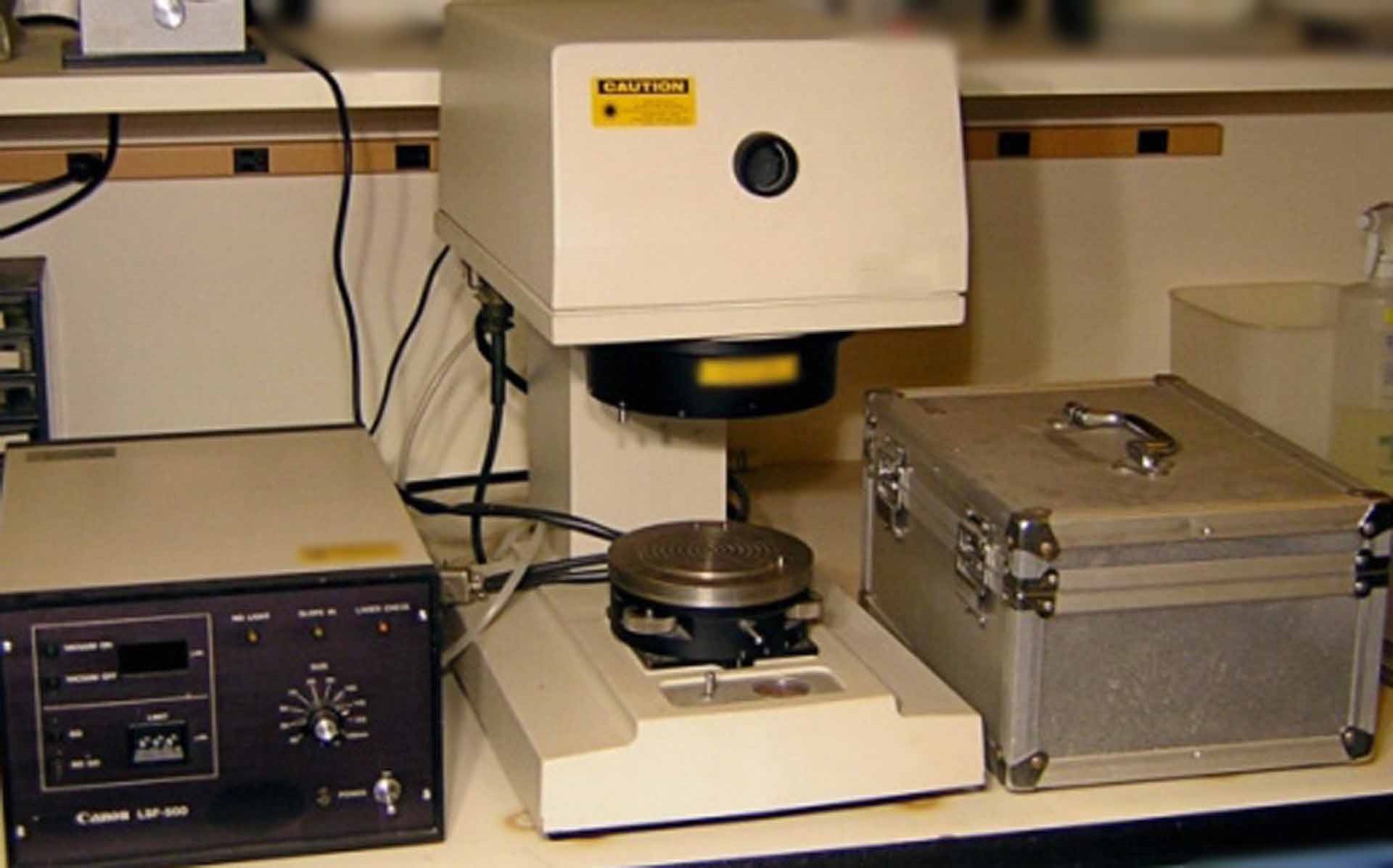

Used CANON LSF 500 #38057 for sale

URL successfully copied!

Tap to zoom

CANON LSF 500 is an innovative wafer testing and metrology equipment that utilizes advanced laser scanning techniques and powerful software to help advance wafer testing and metrology. It is a highly efficient, multi-station system with the ability to measure wafer dimensions, electrical properties, and defects. CANON LSF 500 is designed to be used in a high-volume production environment and can be integrated with production units, such as grinder, polishers, effluent cleaners, and non-contact inspection systems, to provide a comprehensive solution. The unit can measure up to 12 different variables at once, including wafer thickness, surface defects, electrical characteristics, dielectric thickness, and more. LSF 500 utilizes a high-precision laser scanner and imaging technology to ensure accurate wafer measurements. The machine features the ability to measure the X, Y, and Z axes of the wafer with an accuracy of 5um (0.0002 inches), and with extremely fast measuring speeds of up to 20wafers per second. The tool also has high-precision, motorized stages for wafer positioning, as well as a highly efficient, automated feeder asset that can load from 200 to 600 wafers at a time with alignment accuracy of 7-15 microns. LSF 500 also features highly advanced defect control and data analysis capabilities. The model is capable of detecting and categorizing defects with accuracy and repeatability, and the user can set up their own customizable defect criteria to ensure that only the defects they specify are detected and classified. Additionally, the equipment can perform an accurate statistical analysis of the wafer's mechanical and electrical characteristics, so users can quickly spot and identify any abnormalities that may be present. Overall, CANON LSF 500 is an efficient and effective wafer testing and metrology system that is ideal for high-volume production environments. It provides highly accurate measurements, a fast, automated feeder unit, and powerful defect control and data analysis capabilities. These features make it an ideal choice for quickly and accurately measuring and analyzing the performance of wafers.

There are no reviews yet