Used TEL / TOKYO ELECTRON TELINDY B #9014197 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9014197

Wafer Size: 12"

Vertical diffusion furnaces, 12"

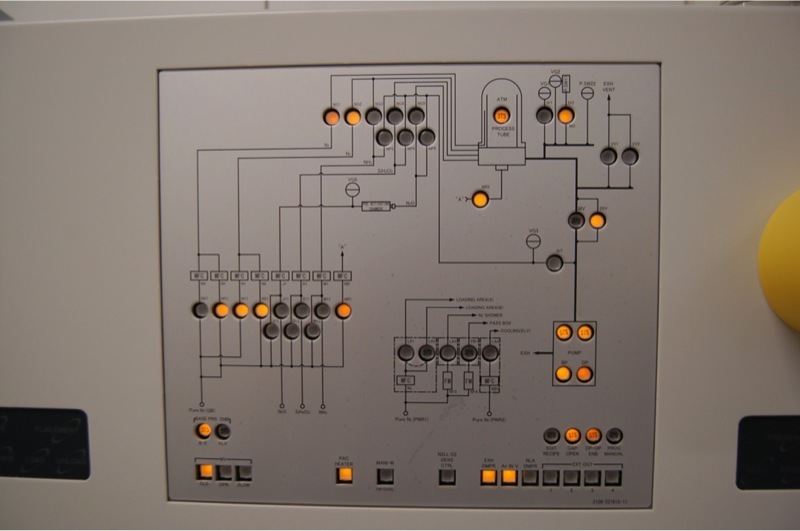

Base unit for DCS HTO process

Includes:

Cabinets / units / controllers included

Furnace cabinet (including ultra-clean air flow system)

Scavenger and water cooling unit

Power supply unit (U/P box)

(Includes control unit, transformers, SCR, and breaker unit)

Main controller (WAVES)

Temperature controller

FOUP and wafer handling automation included

FOUP load port

FOUP transfer

18 FOUP stocker

FIMS port

KHI wafer load automation

Variable pitch change mechanism (w/5 fork)

Auto tube shutter

Boat elevator w/ boat rotation mechanism

Mid temp heater: VMM-56-002 1 Included

Includes outer/inner T/C

Integrated gas system for DCS HTO 1 Included

N2O gas stick 1 stick Included

DSC gas stick 1 stick Included

Purge N2

Vacuum vent

Exhaust vent

Piping tape heater

PAC (Pre Activation Chamber)

Vacuum foreline configurations

Stainless steel manifold

80A foreline piping

Foreline heater

APC main valve

Vacuum gauge & pressure switch

US safety (S2-0302, S8-0999)

Quartzware set for DCS HTO 1 Included

(Including x2 of 75 slots Ladder Boat)

System options:

N2 Load lock option 1 Included

- O2 analyzer - NGK SH-302

- O2 consumption rate controller

Dual boat operation 1 Included

N2 boat cooling shower 1 Included

Fixture for start up and maintenance 1 Included

Final valve unit 1 Included

NH3 coating capability

Hi-temp capacity (<850°C)

2007 vintage.

TEL / TOKYO ELECTRON TELINDY B is a type of etcher, also known as an asher. It is a semiconductor and photovoltaic device fabrication equipment comprising a vacuum system, a process source unit, and a process unit. It uses electron beam technology and a dedicated software machine to control the etch process in both uniformity and accuracy. The etcher relies on three main components of its tool - the vacuum asset, the process source model, and the process unit. The vacuum equipment pumps out air and gas from the chamber and central to it is the turbomolecular pump. On the other hand, the process source system plays a key role in supplying the plasma source gas, which are accessed through an integrated network of mass flow controllers, pressure controllers, and multi-gas perforated tubes. Lastly, the process unit delivers the etch process within the chamber by controlling the applied gas pressures, flow rates, power and timing of the unit. TEL TELINDY B etcher can offer high accuracy and control within the etching process due to the electron-beam evaporator. This beam is used to control the evaporation of thin films sources in thickness control and it also has the ability to selectively coat plates. The etcher also allows for the arrangement of many process layers for etching through the use of a wafer CD (critical dimension) measurement machine. TOKYO ELECTRON TELINDY B etcher also has excellent temperature control capabilities, which can help regulate uniformity amongst different substrates. One of the added benefits of this etcher is that the operator has the ability to utilize process parameters such as chamber pressure, cooling gas pressure, and gas flow rate in order to tailor the etching process to their needs. Finally, the etcher is highly advanced as it is equipped with an intuitive software tool that allows the operator to optimize the etching process as well as automate many of the tasks. This makes it easier for the operator to adjust different process parameters and be sure that the outcome of the etching process is consistent and accurate. Overall, TELINDY B is a highly advanced etcher which features an electron beam evaporator to ensure accuracy and control over the etching process. Operators can utilize the process parameters to tailor the etching process to their needs, while the intuitive software asset ensures ease of use and automation of certain tasks.

There are no reviews yet