Used ALLWIN21 AW 105R #9201878 for sale

URL successfully copied!

Tap to zoom

ID: 9201878

Wafer Size: 2"-6"

Plasma etcher, 2"-6"

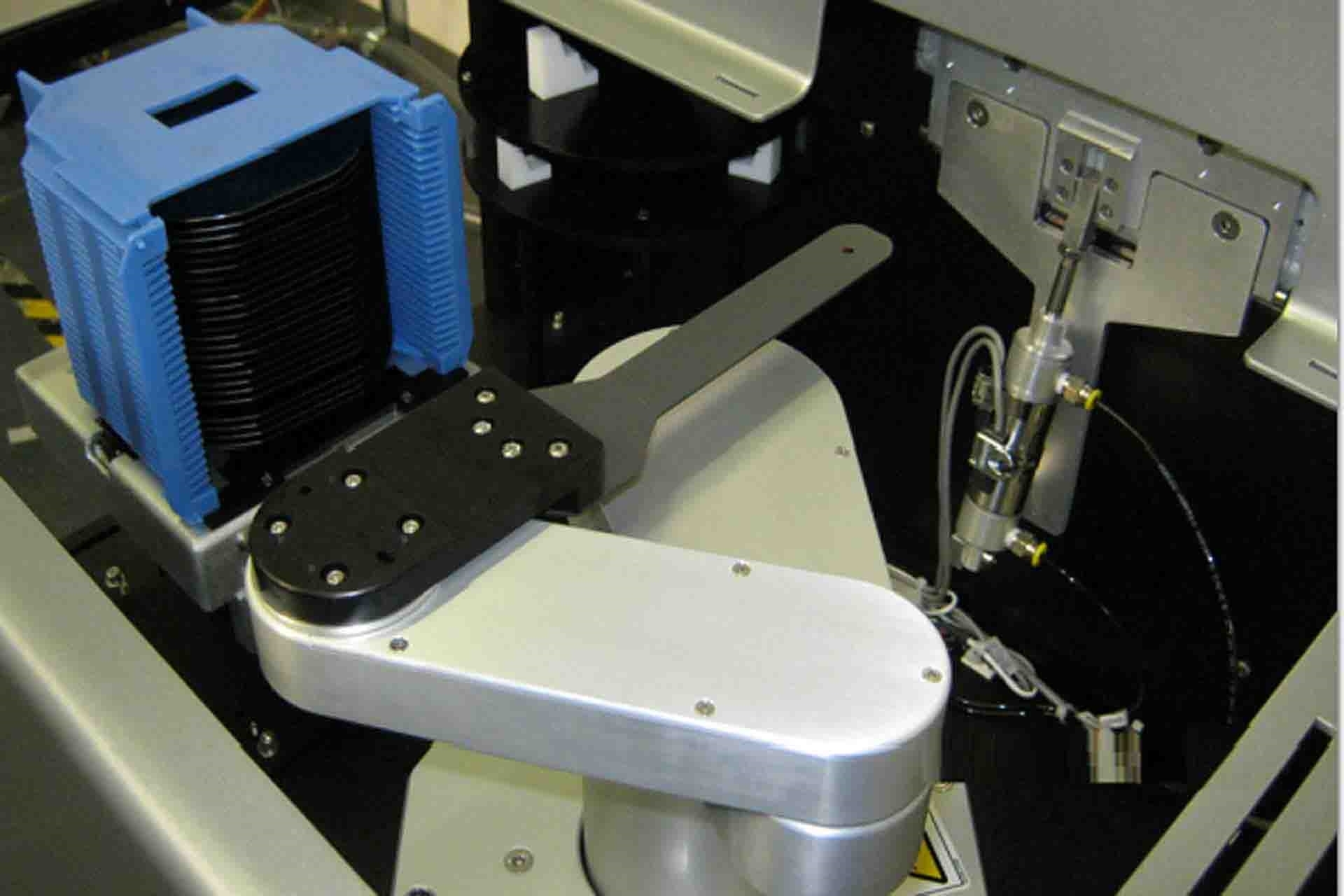

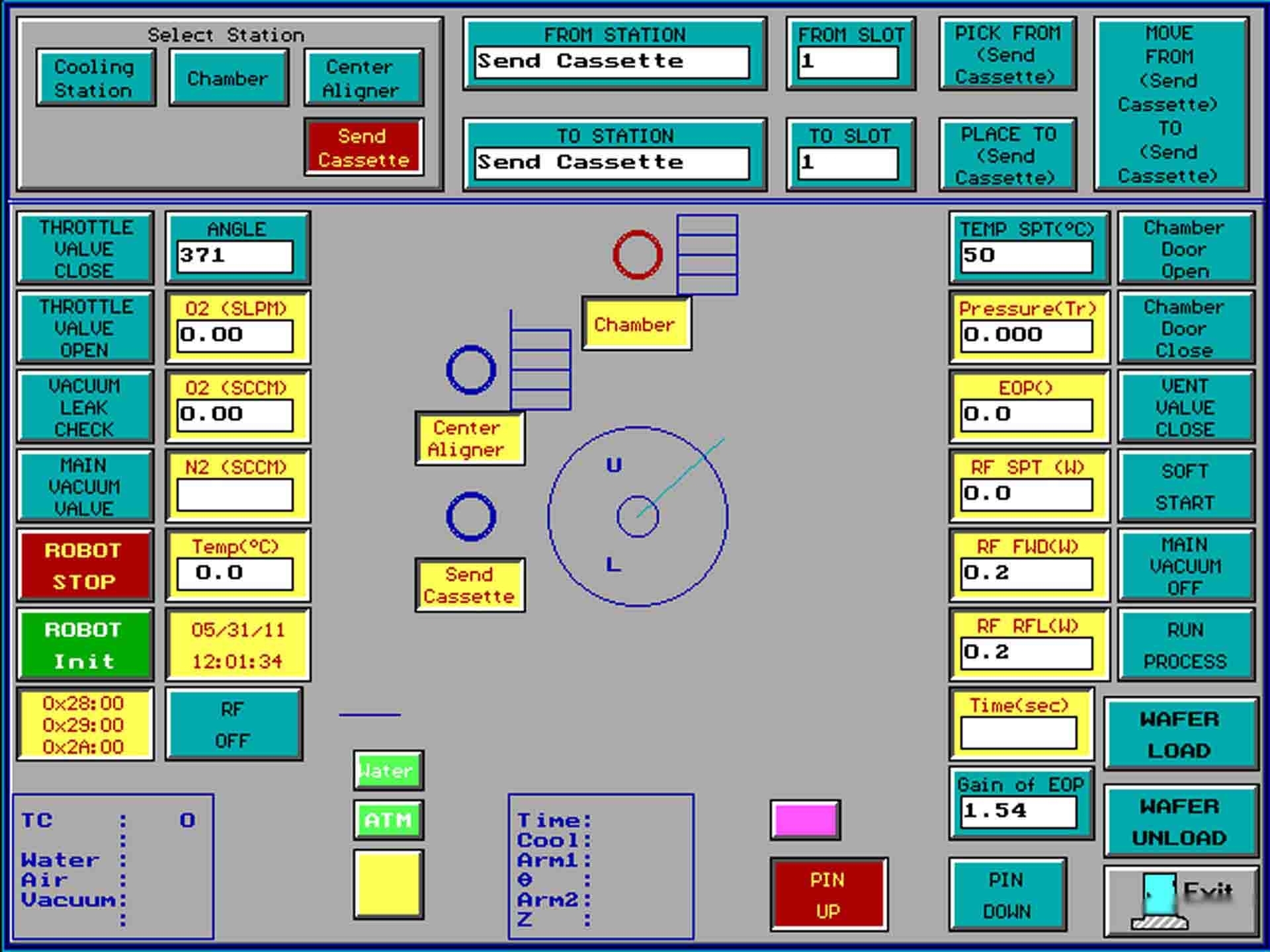

Wafer loading: 3-Axis robot

Stationary cassette plate

Plasma power: 600W Air-cooled

Type: Parallel / Single wafer process

Gas lines: 1-3 Lines MFCs

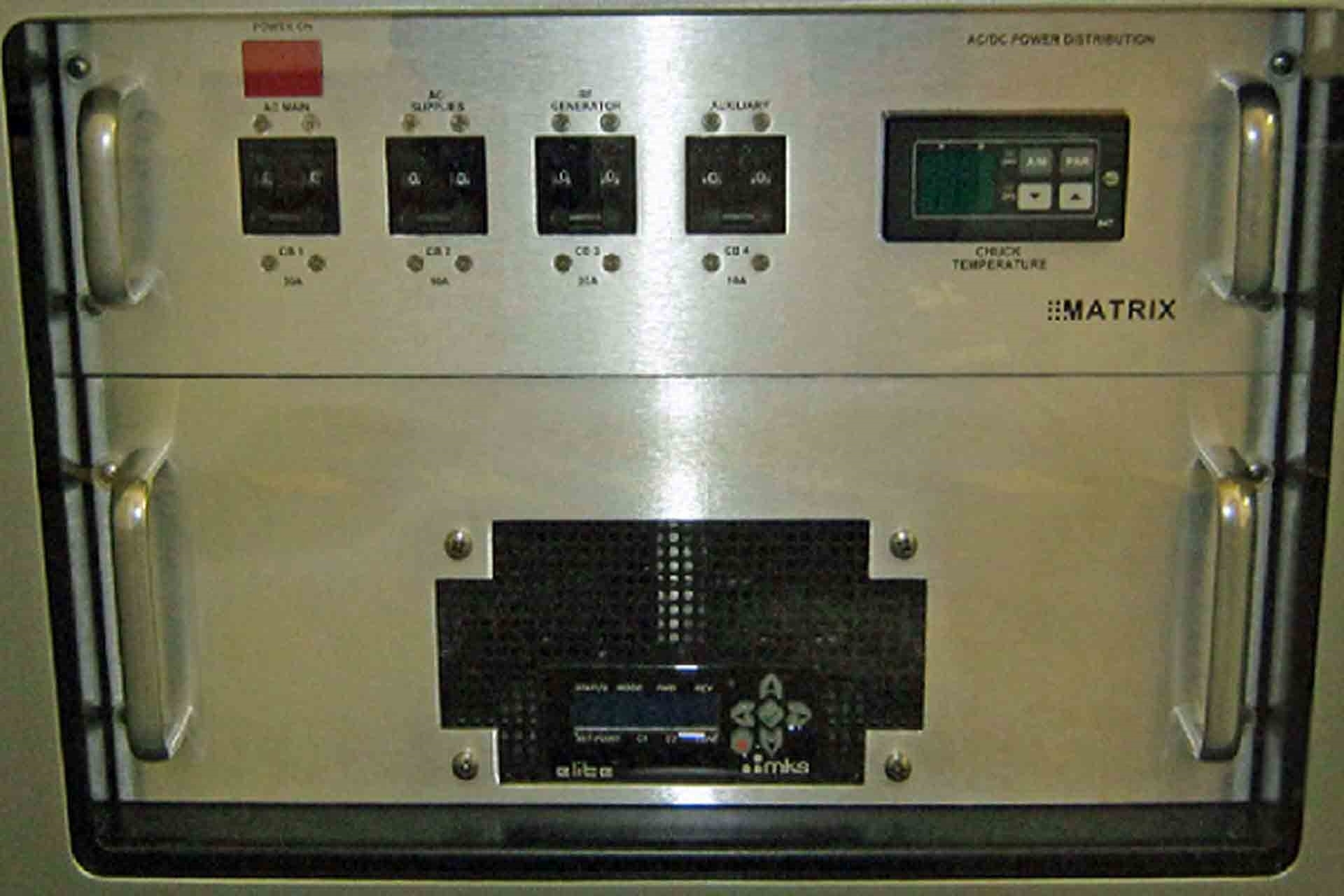

Main frame with circuit breakers, solenoid valves

Keyboard, mouse, cables

Anodized reactor with door

Chamber base plate with water sensor

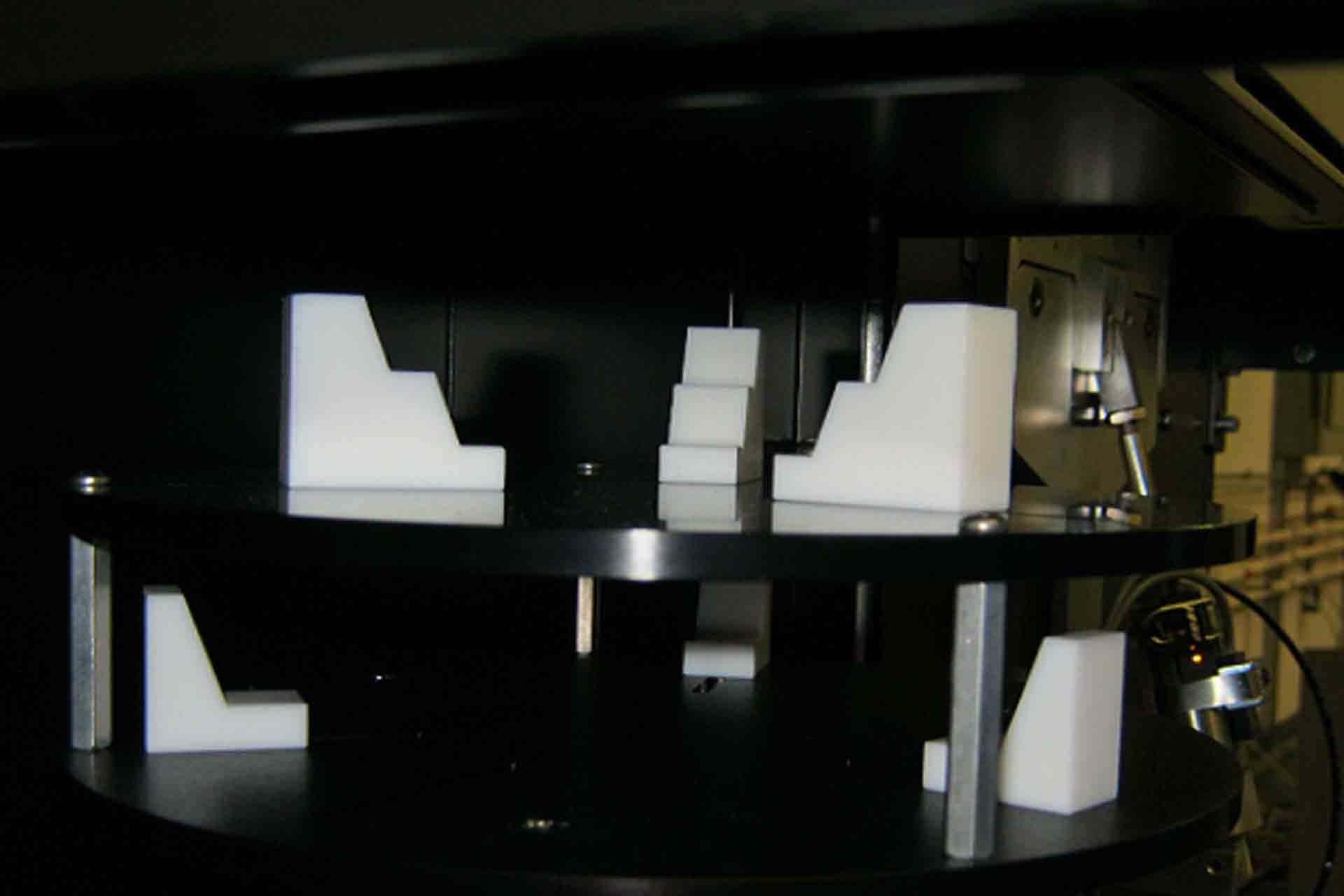

Upper and lower electrodes

Quartz showerhead & diffusion disk

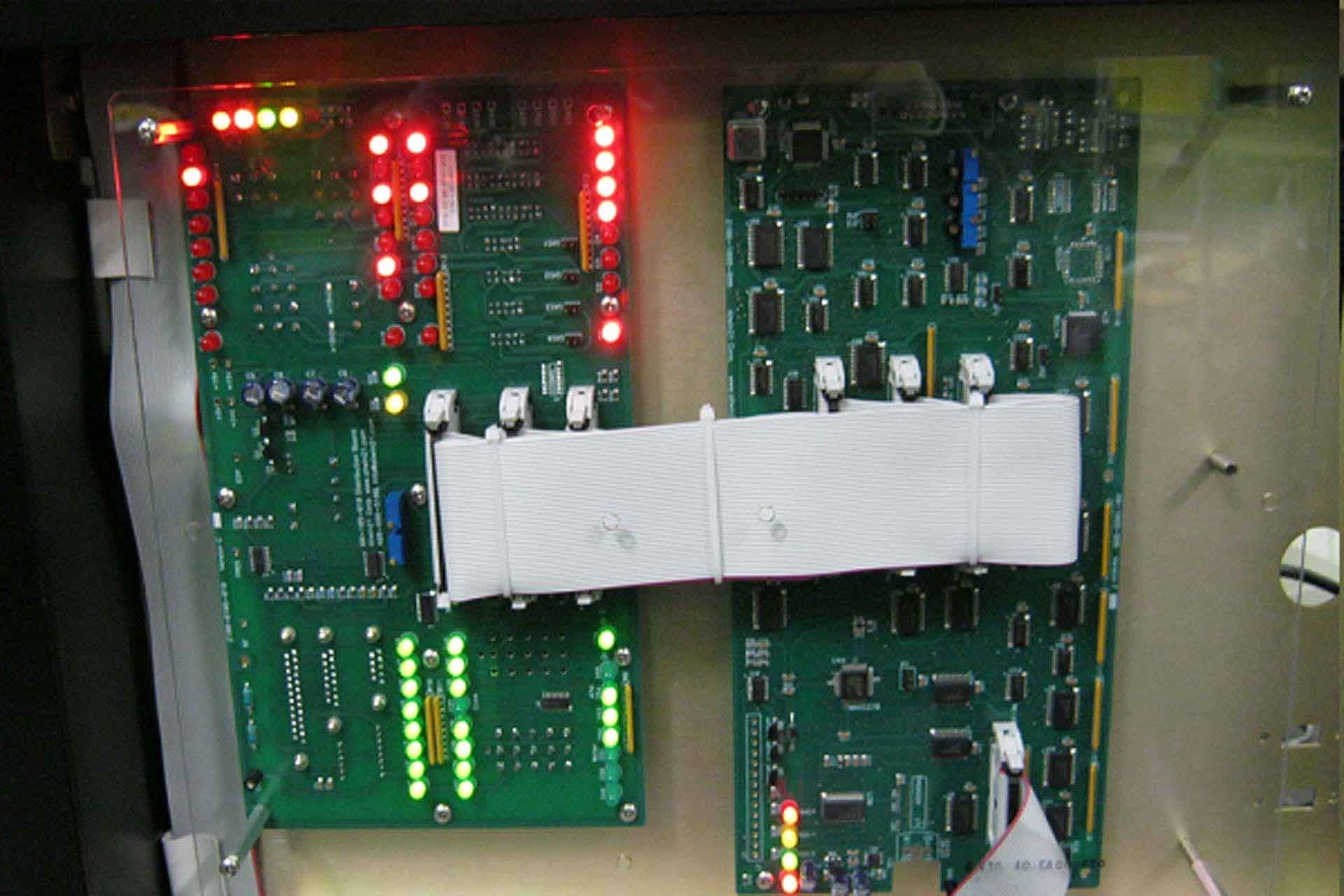

Main control and distribution PCBs

RF Matching network with PCBs

RF Generator: 13.56MHz

Center aligner / Cassette station:

Two dimensions

Four dimensions

Base plate and ceramic ring:

Reactor

Chuck

In-line filter and solenoid isolation valve:

One MFC

Two MFCs

Three MFCs

AC/DC Box: Temperature controller

MKS Baratron: Isolation valve

Throttle valve

Main vacuum valve

Front EMO, interlocks

Touch screen GUI, 15"

Asher rate: 0.5-1.5 um/Min (200 to 250 ºC)

Bulk strip: 600 A/Min (100 ºC)

Uniformity: <±8% (Max-min)

Strip: <±5% (Max-min)

Particulate: <0.05/cm2

Selectivity: >1000:1

MTBF / MTTA / MTTR: 450 Hours / 100 Hours / 3.5 Hours / Better

Production-proven plasma asher / Descum

Uniformity: Up to 3%-5%

Frontside and backside isotropic removal

Consistent wafer-to-wafer process cycle repeatability

Element heating: Up to 250°C

Wafer capability (50mm-150mm): Up to 6.25” substrate

Thickness wafer: 50um

Options:

End-of-process (EOP)

Vacuum pump

Chiller: Chamber base plate

Applications:

GaAs, InP, GaN, SiC Wafer strip

GaAs, InP, GaN, SiC Wafer descum

Thin film head resist cleaning

Opto-electronic devices cleaning

MEMS

Photoresist stripping:

High dose implant

Rework

Post-polysilicon

Post-metal

Post-oxide

Controlled resist removal:

Post-develop descum

Uniformity capability: (<5% 1σ)

Plumbed process gases: O2, N2

Cooling water: GPM House circulating supply

Facility exhaust: 100 CFM

Power: 190-240VAC, single phase, 30A, 50/60Hz.

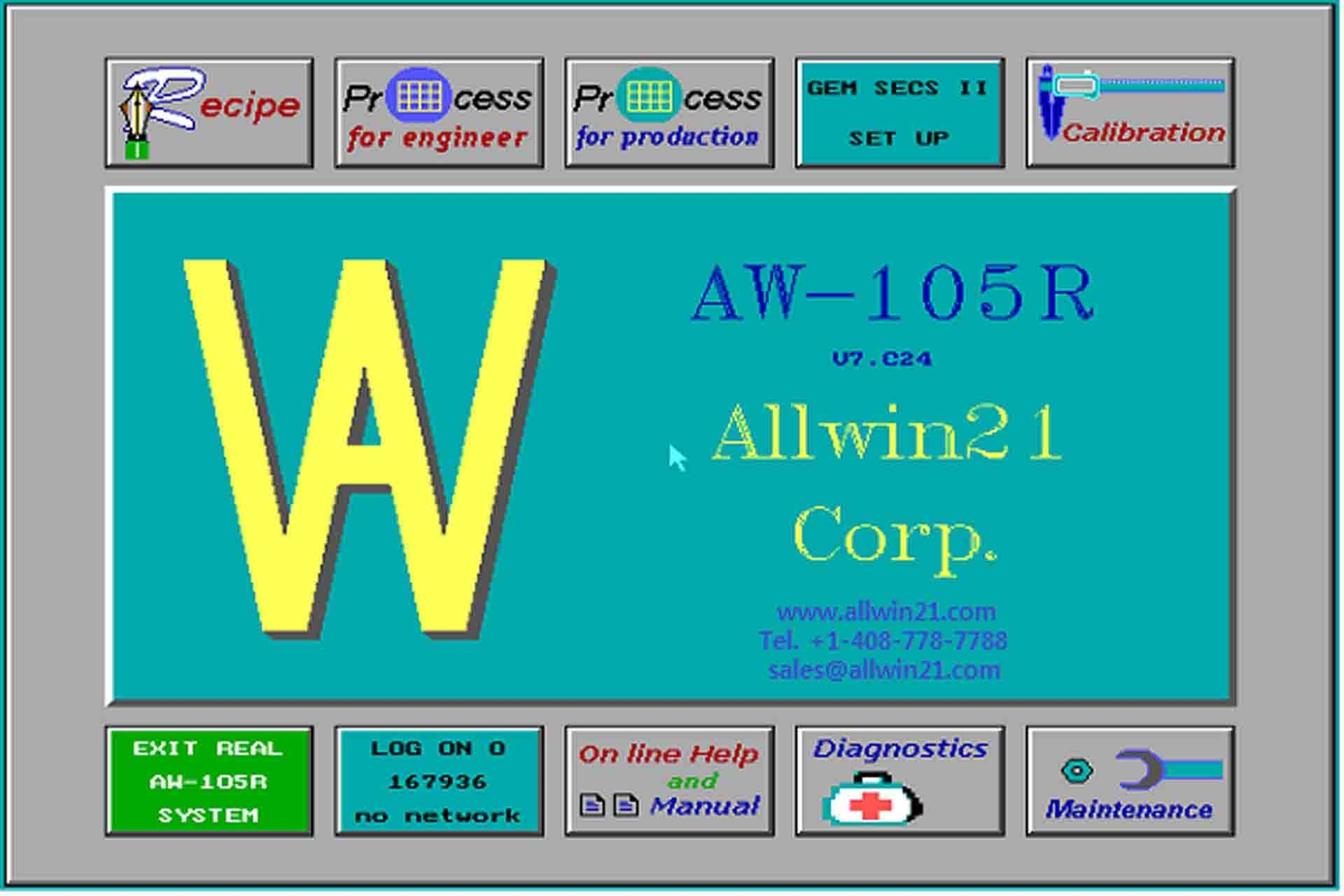

ALLWIN21 AW 105R Rapid Thermal Processor is a precise thermal processing equipment ideal for a wide range of research and industrial applications. The state-of-the-art equipment utilizes a robust graphite heating block for consistent performance in temperatures up to 1250°C, and an ultra-precision temperature controller to provide unparalleled accuracy and stability during operation. AW 105R is engineered to enable rapid heating and cooling cycles, with an average time of 5 minutes. This allows for efficient and effective processing of any size material without sacrificing precision. ALLWIN21 AW 105R employs a rated power of 8.5kW, and features a unique interlocked door system to maximize safety during operation. The unit includes an intuitive graphical user interface, a vacuum-thermology process control, and an Anemometer/Humidity meter to ensure a safe and clean process environment. The machine is designed for easy maintenance and efficient operation. AW 105R Rapid Thermal Processor features a simple vacuum pumping tool and a high-quality graphite heating block with independent temperature measurement. With a fully automated control panel, users can quickly get up and running with minimal setup. ALLWIN21 AW 105R is equipped with a powerful motorized stage and a wide range of accessories, including quartz chambers, lifting devices, and multiple wafer heights. The asset is compatible with a variety of material substrates: Silicon wafers, polymer films, carbon nanotube arrays, biosensors, and more. AW 105R is capable of processing in Micro-Electro Mechanical Systems (MEMS) conditions, and a Fourier Transform-Infrared (FT-IR) analyzer is used to ensure highest quality analysis of obtained samples. The entire machine is modular and designed to accommodate a variety of future developments. In short, ALLWIN21 AW 105R Rapid Thermal Processor is the perfect equipment choice for those looking to quickly process a wide range of materials with complete accuracy and temperature control. With its high power rating and easy-to-use features, researchers can be sure that their sample is processed exactly as required without sacrificing any level of precision.

There are no reviews yet