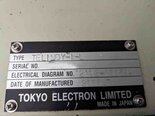

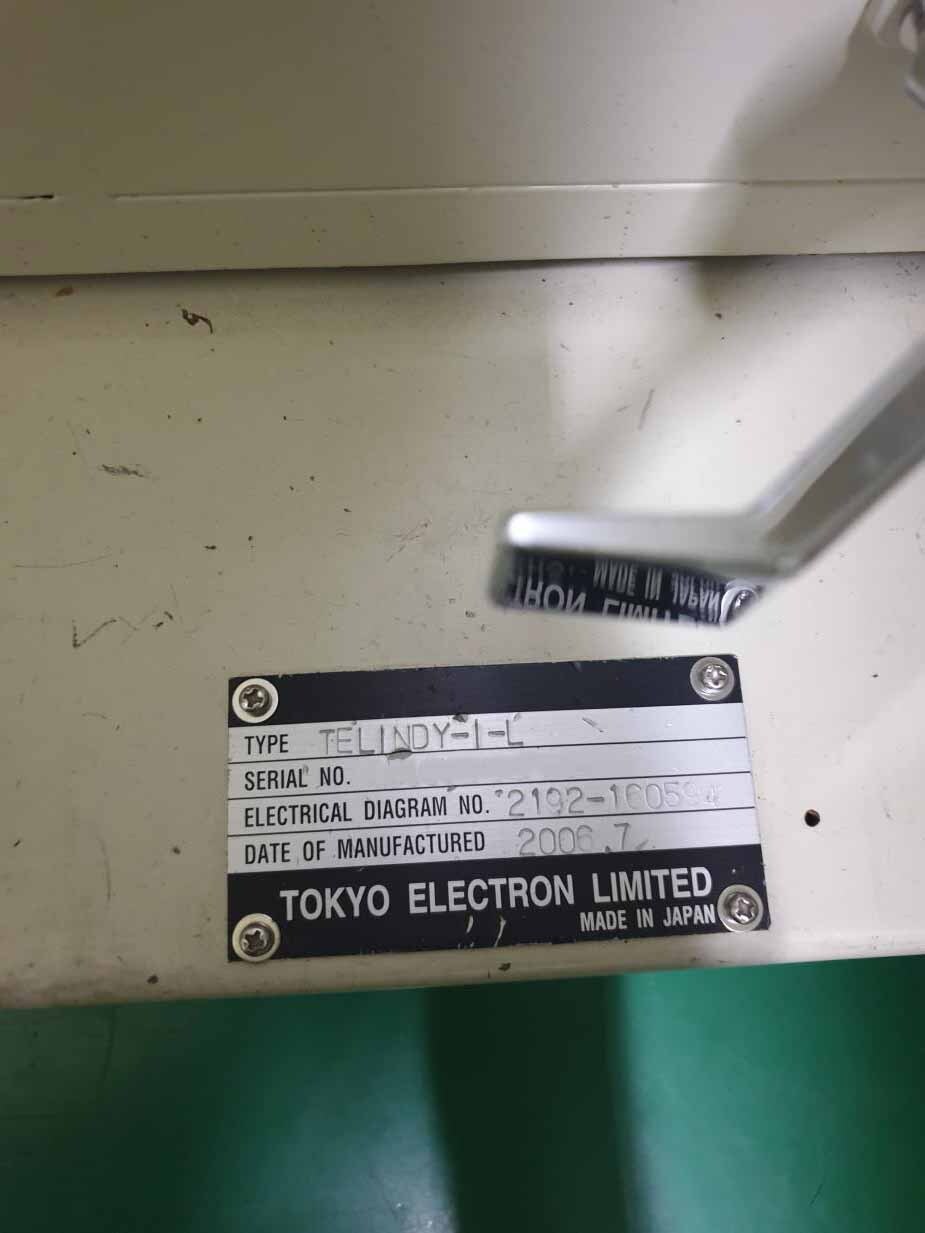

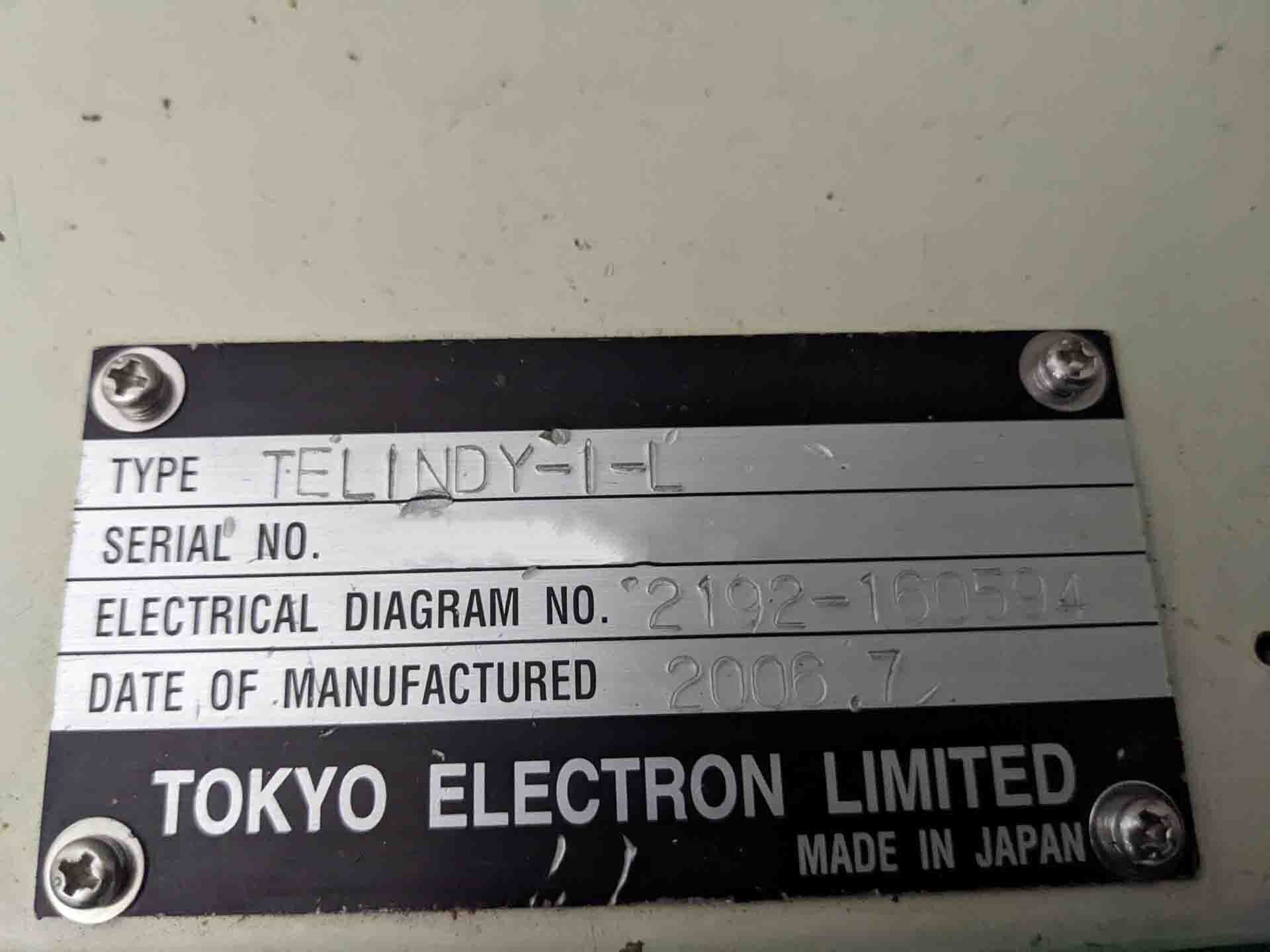

Used TEL / TOKYO ELECTRON Indy-I-L #293622284 for sale

URL successfully copied!

Tap to zoom

ID: 293622284

Wafer Size: 12"

Vintage: 2006

Vertical furnace, 12"

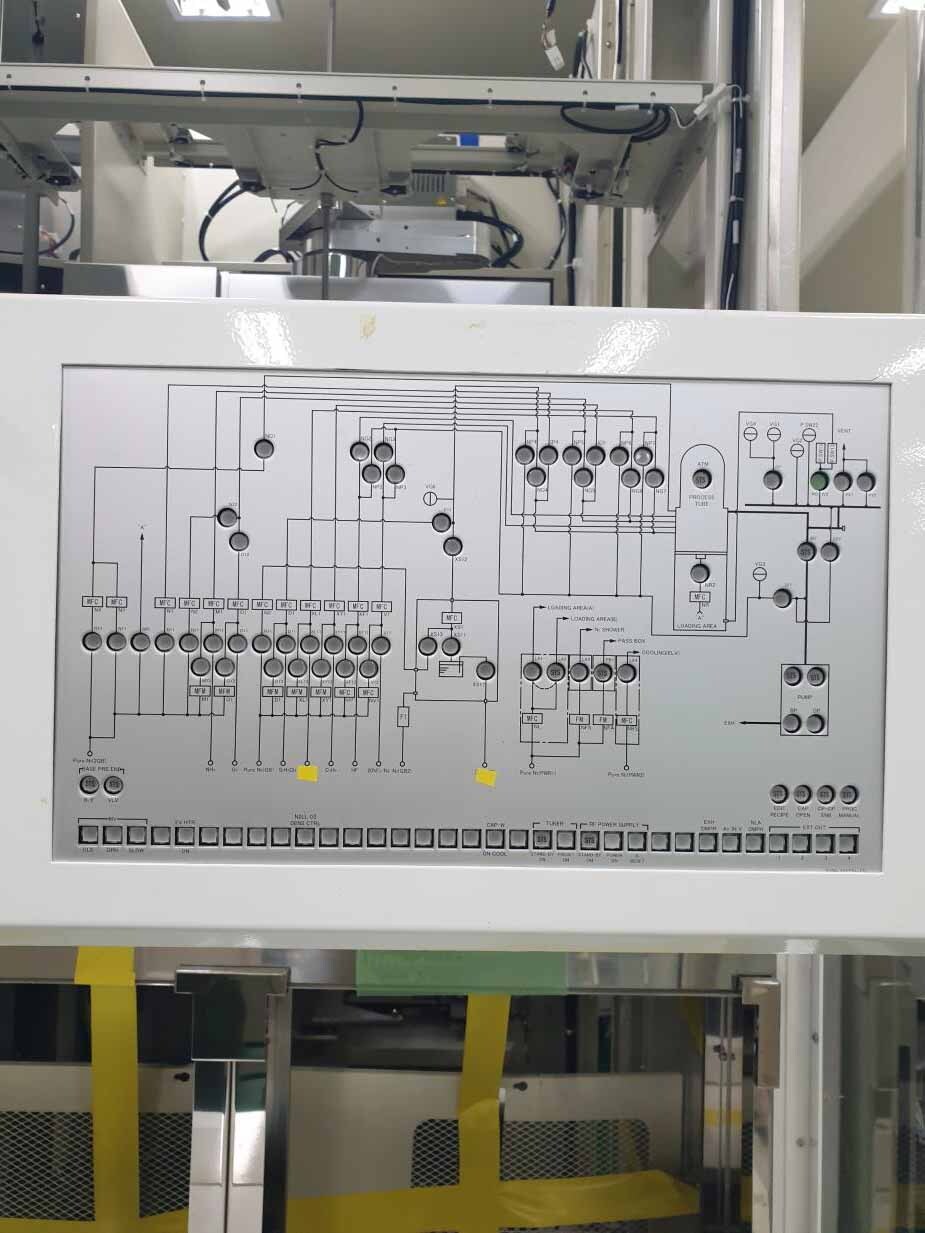

Process:

NH3

DCS

SiGe

C2H4

HF

20% F2 with N2

TiCl3 liquid

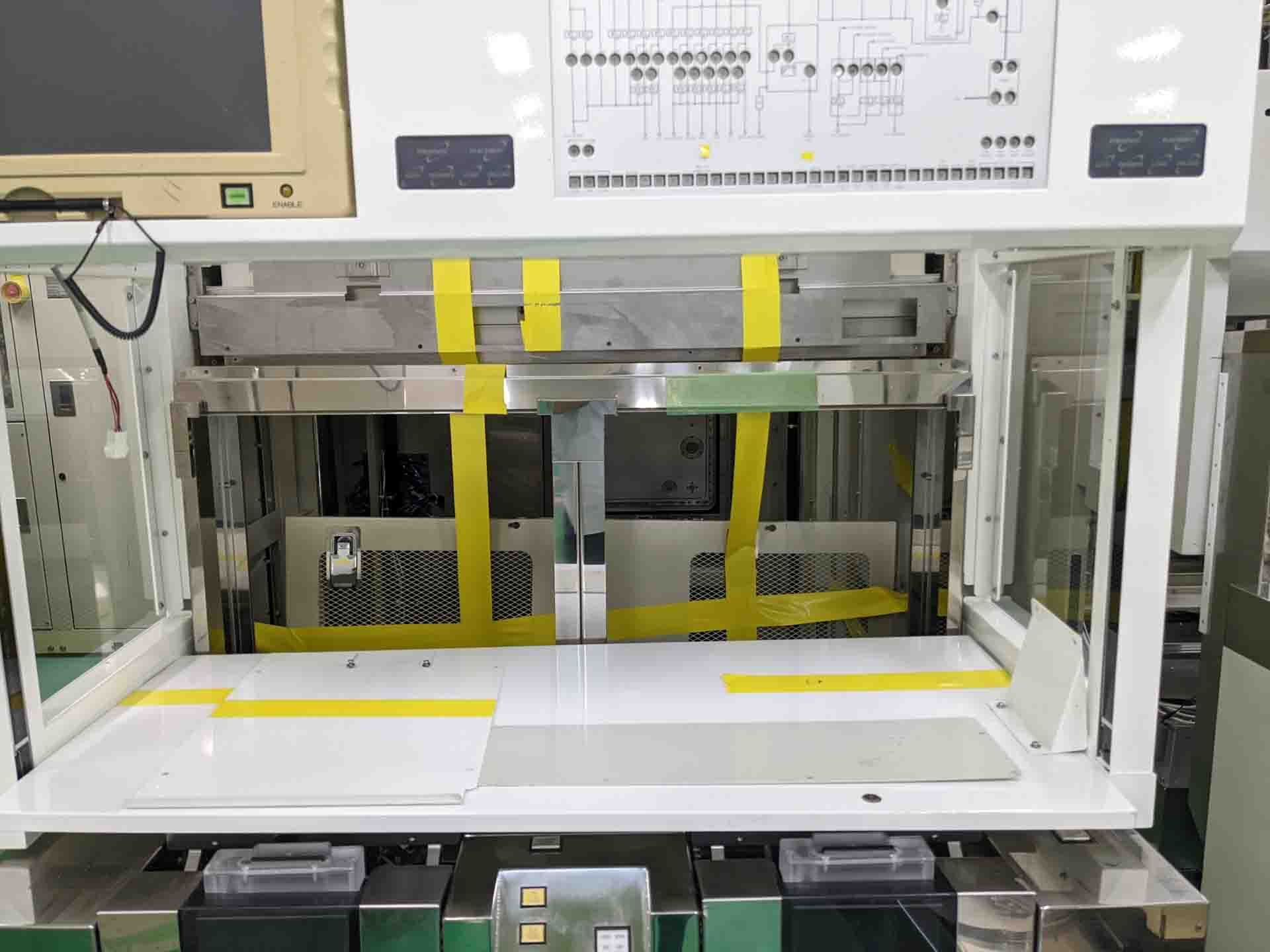

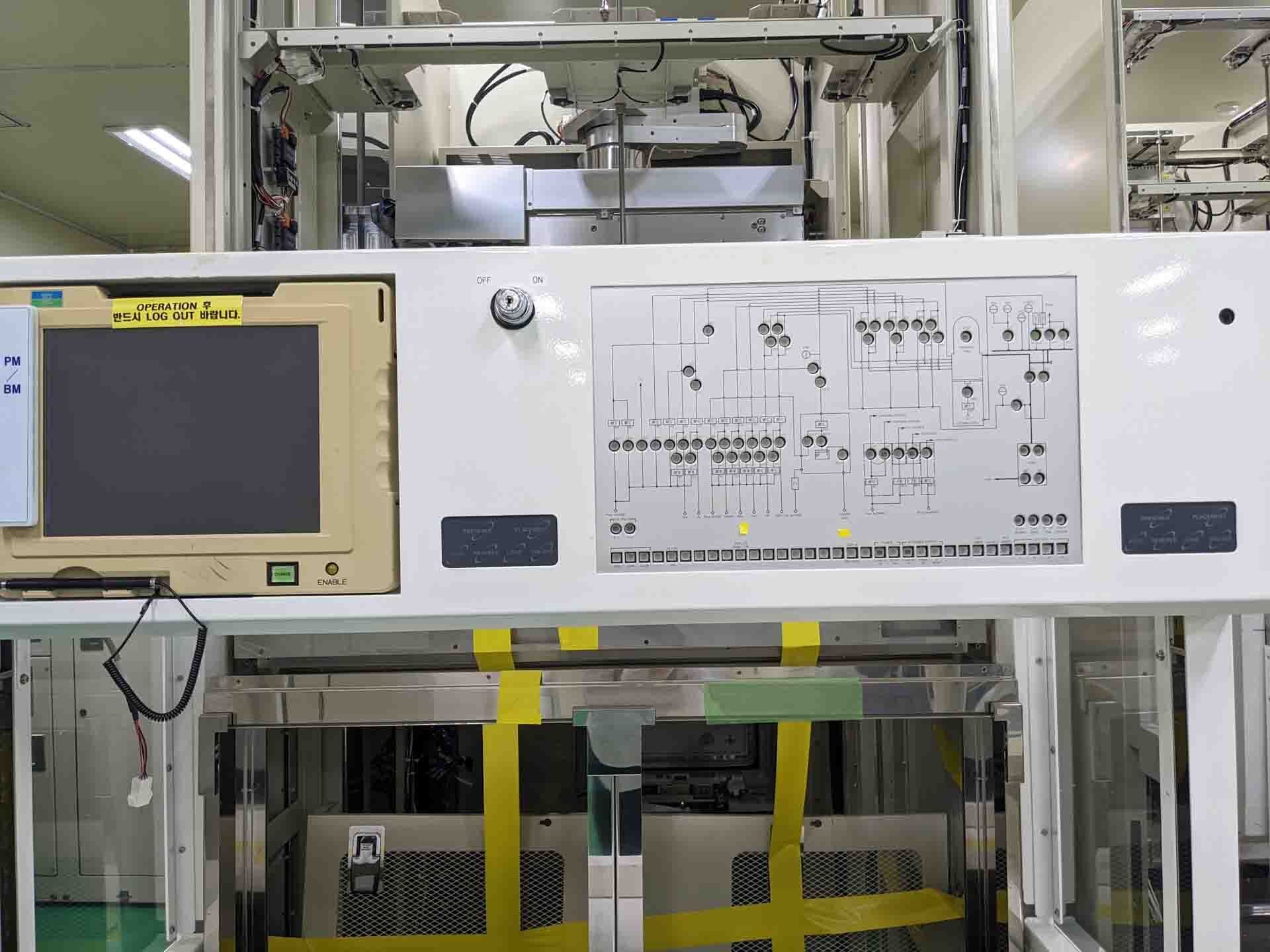

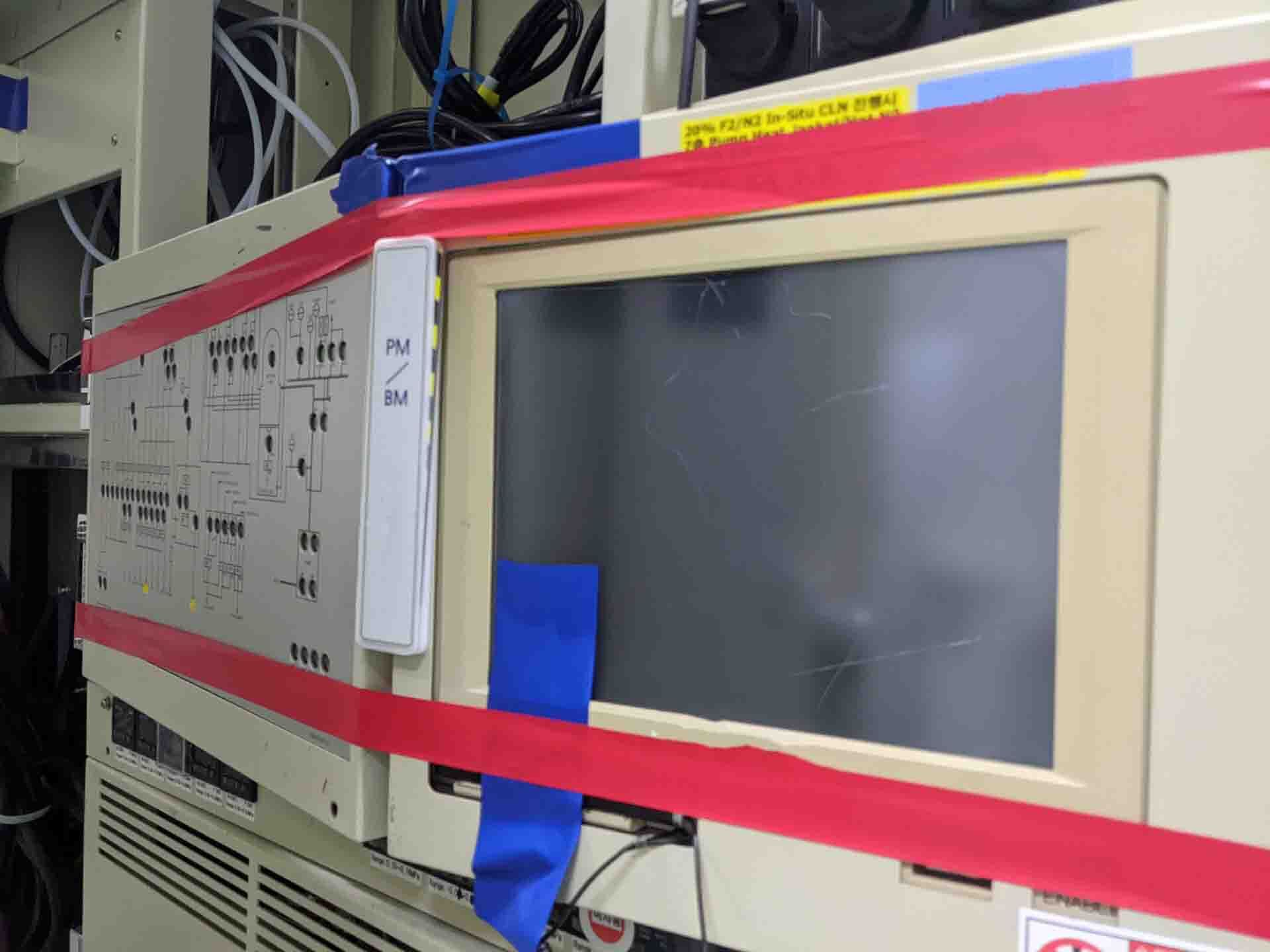

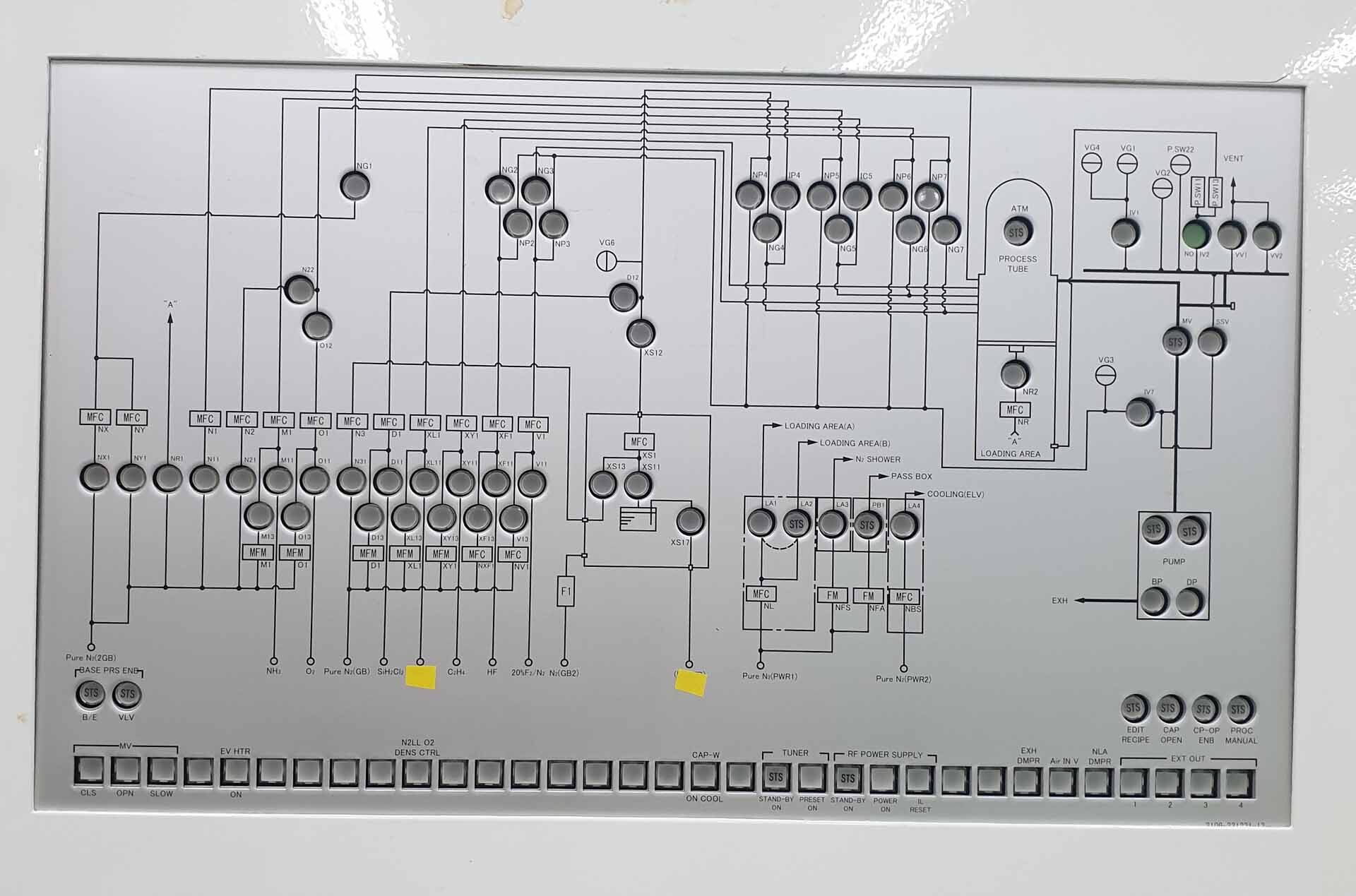

Operation panel

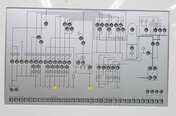

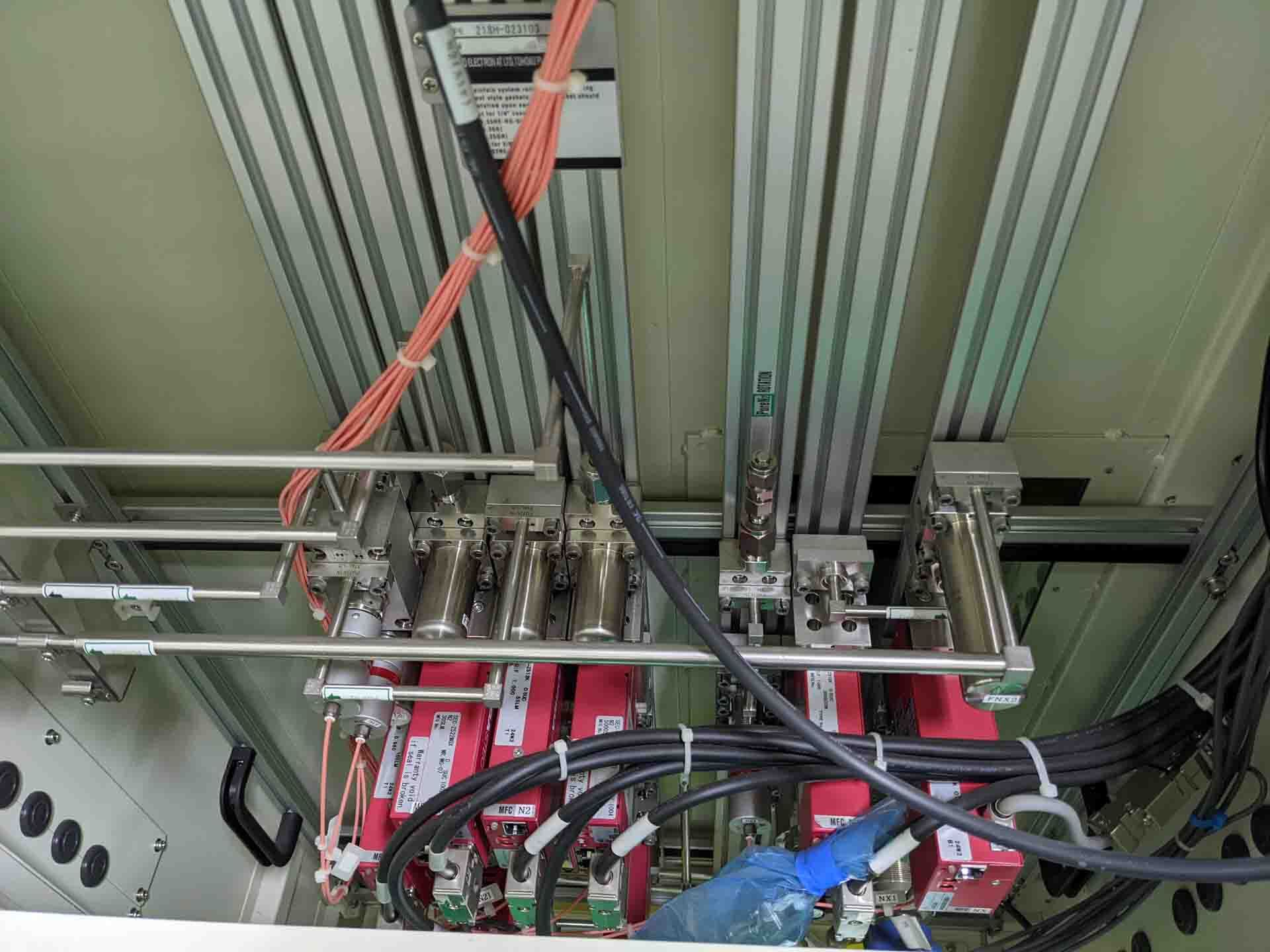

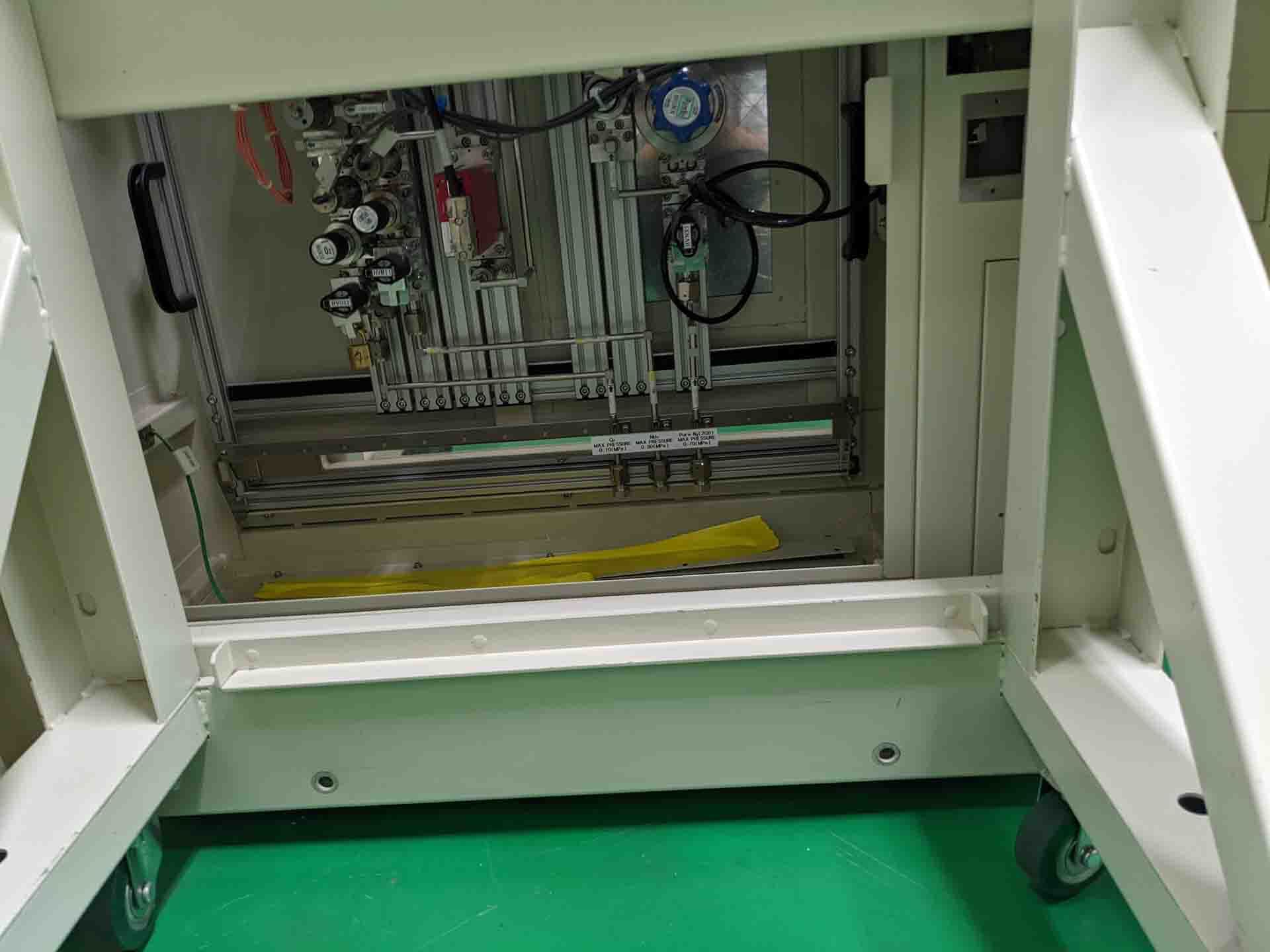

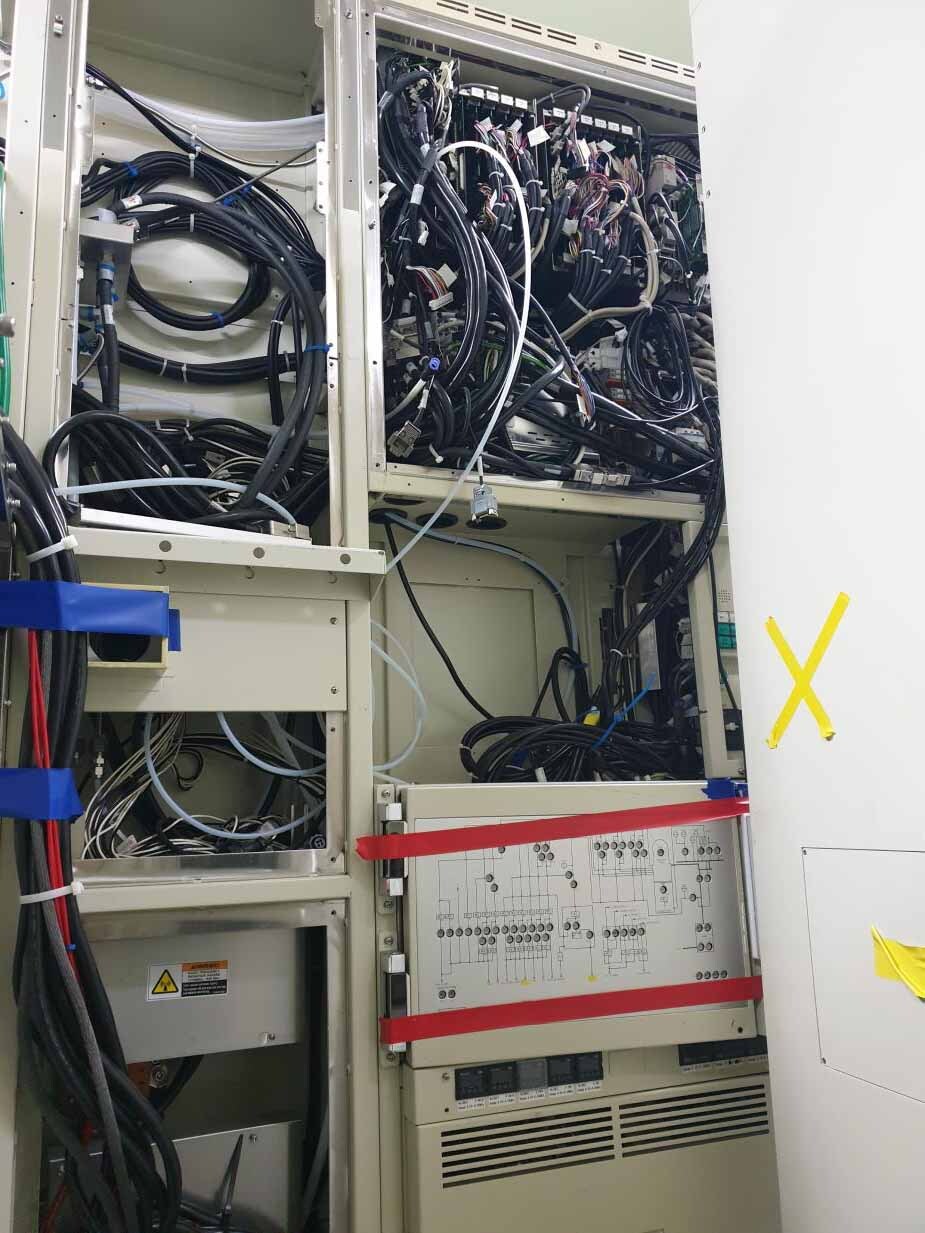

IO Unit

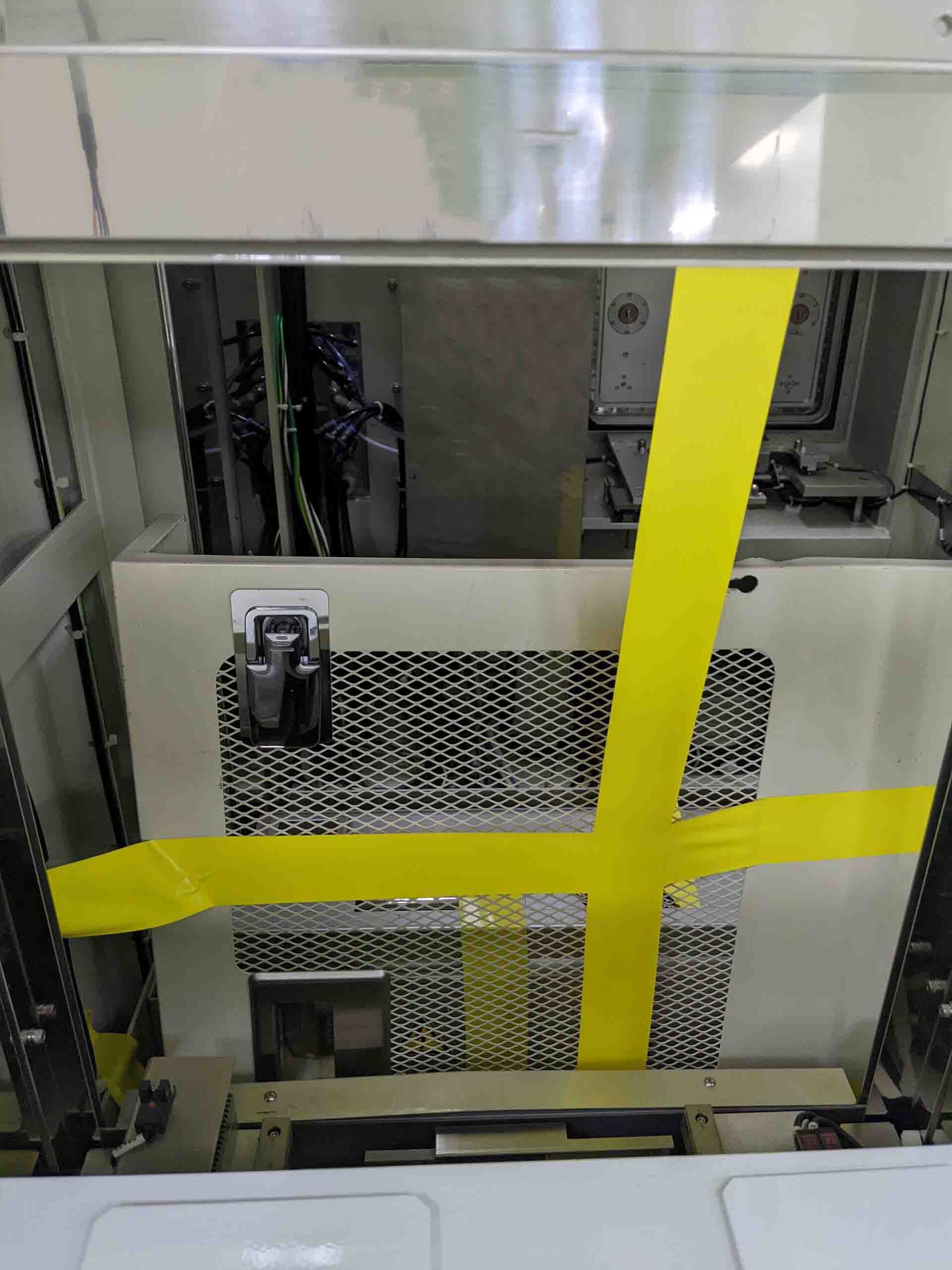

Exhaust box

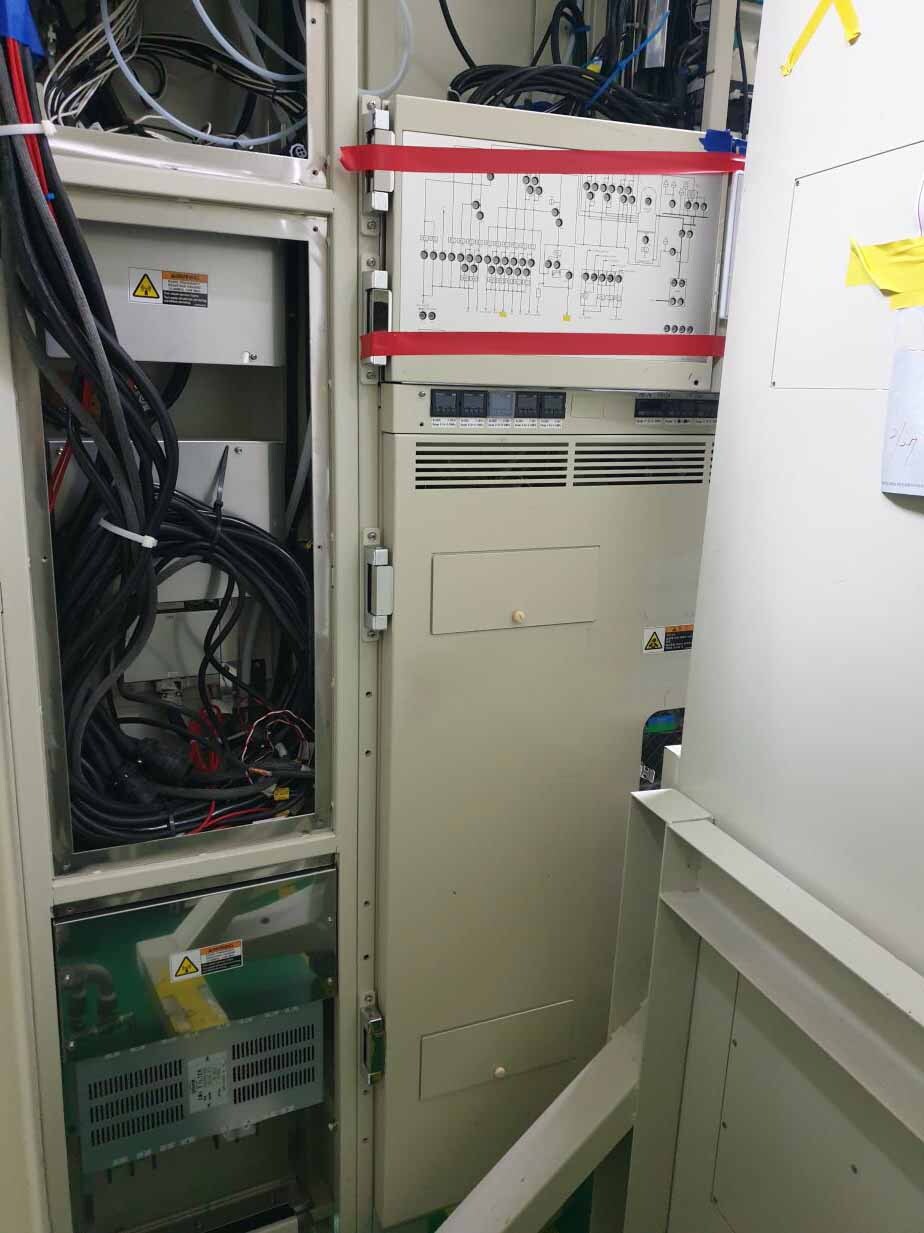

Power box

Heater

2006 vintage.

TEL / TOKYO ELECTRON Indy-I-L is a versatile etcher/asher that is used in semiconductor manufacturing. It is an inductively-coupled plasma-based (ICP) etcher/asher that uses an advanced technology perforation windowless etching equipment to achieve high-precision, high-quality etching and ashing results. TEL Indy-I-L features a powerful, yet stable high-frequency power supply that delivers a precise amount of power to the etching surface with superior repeatability. This precision power control allows for the etching of hard-to-process materials such as low-temperature polysilicon and cobalt. The unit also features an advanced atmospheric control system that is capable of maintaining a normal and stable pressure in the reaction chamber. The chamber is equipped with both a pressure transducer and a pressure regulator, allowing for precise pressure control. TOKYO ELECTRON Indy-I-L is also equipped with TEL proprietary RIE SPRON-H technologies, which was developed to provide the highest possible etching rates and process uniformity. This proprietary technology has improved the etching rate by up to 40%, allowing for shorter cycle times and higher levels of repeatability. The etching process on Indy-I-L is further optimized by the unit's advanced, automated recipe management unit. By providing the precise process time and energy per stage of the etching cycle, the machine ensures that the resulting products meet all manufacturers' specifications. In addition, TEL / TOKYO ELECTRON Indy-I-L is designed for maximum flexibility and the ability to adapt to changing production requirements. The unit can be set up for both single and multiple wafer loads, and the dedicated hardware can be changed quickly and easily to accommodate different sized substrates. TEL Indy-I-L is designed to provide reliability and cost-effectiveness for chip makers, making it a valuable tool for semiconductor manufacturing. With its advanced design and sophisticated control tool, the unit is highly reliable and capable of delivering consistent, high-precision etching and ashing results.

There are no reviews yet